We remove the cylinder head to replace the gasket, repair the valve drive mechanism and the head itself, as well as during complete disassembly of the engine

We carry out the work on an inspection pit or lift.

To replace the head gasket or connecting rod and piston group of the engine, we remove the cylinder head from the engine assembled with the receiver, intake pipe and exhaust manifold.

To dismantle the cylinder head:

- - disconnect the negative cable of the battery;

- - drain the coolant (see Replacing the coolant);

- - remove the throttle assembly (see Removing the throttle assembly);

- - disconnect the hoses from the outlet pipe of the jacket cooling;

- - disconnect the hose from the heater radiator inlet pipe;

- - disconnect the fuel rail injector wire connector (see Removing the fuel rail);

- - disconnect the connectors from the injection system coolant temperature sensor and the coolant temperature gauge sensor;

- - remove the high-voltage wire tips from the spark plugs;

- - disconnect the fuel supply and outlet pipes from the fuel rail;

- - disconnect the inlet pipe from the exhaust manifold (see Removing the inlet pipe), the starter heat shield and the heater radiator outlet pipe bracket;

- - remove the camshaft and valve drive levers (see Removing the camshaft and valve drive levers);

- - remove the camshaft sprocket and tie the chain with wire.

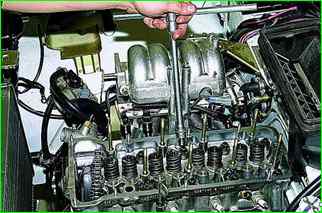

With a "13" head unscrew the cylinder head mounting bolt located next to the ignition module bracket.

Using a 12 mm socket, unscrew the ten bolts securing the head to the cylinder block.

Take out the bolts.

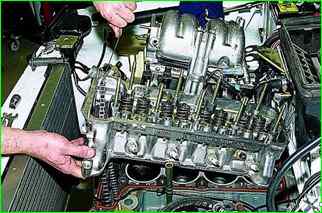

Remove the cylinder head assembly with the exhaust manifold, receiver and intake pipe with the fuel rail.

The cylinder head can also be removed from the engine, having first dismantled the receiver (see. Removing the receiver), the intake pipe and the exhaust manifold.

Removing the cylinder head without the exhaust manifold and intake pipe

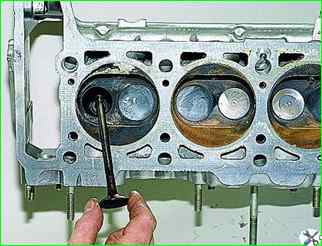

Removing the cylinder head gasket.

Installing the cylinder head on the workbench.

Using a 10 mm socket, unscrew the two nuts securing the heater radiator inlet pipe to the cylinder head and remove it.

Removing the sealing gasket.

Using a 13 mm socket, unscrew the two nuts securing the outlet pipe of the cooling system jacket and remove the pipe with the coolant temperature sensor of the injection system

Removing the pipe sealing gasket.

When disassembling the valve mechanism, place a stop - a wooden block - under the valve plate to be decompressed.

Decompress the valve (see Replacing the valve stem seals of the valve timing mechanism) and remove the valve from the cylinder head guide sleeve.

Remove the other valves in the same way.

Assemble and install the cylinder head in the reverse order.

Before installing the valves, clean them from carbon deposits and lubricate the valve stems with engine oil.

After assembling the valve mechanism, strike the ends of the valves with a hammer with a plastic striker to secure the crackers more securely (the wooden stop must be removed from under the valve plate)

Before installing the cooling system pipes, clean the mating surfaces of the pipes and the cylinder head from the remains of the old gaskets.

Install new pipe gaskets, applying a thin layer of sealant to them.

Clean the mating surfaces of the head and cylinder block from the remains of the old gasket, dirt and oil.

Use a syringe with a needle or a rubber bulb to remove oil and coolant from the mounting holes of the cylinder block.

We install the gasket and the cylinder head on two centering bushings

When installing the head on the cylinder block, thread the chain by the wire through the hole in the head

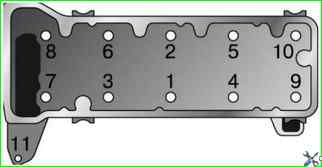

After installing the cylinder head mounting bolts, tighten them in the order shown in the figure.

To ensure a reliable seal and eliminate the need to tighten the bolts during vehicle maintenance, tighten the bolts in four steps:

- Step 1 – tighten bolts 1–10 to 20 N⋅m (2.0 kgf⋅m);

- 2nd step – tighten bolts 1–10 to 69.4–85.7 N⋅m (7.1–8.7 kgf⋅m), and bolt 11 to 31.4–39.1 N⋅m (3.2–4.60 kgf⋅m).

Then tighten bolts 1–10 by 90° (3rd step) and another 90° (4th step).