The cuff can be replaced without removing the gearbox from the car

To do this, hang up the rear axle, drain the oil from the crankcase, remove the wheels and brake drums, and disengage the axle shafts from the differential gears (see the article on removing the axle shafts - How to remove and repair the axle shaft of the rear axle of the VAZ-2121).

Disconnect the propeller shaft from the flange of the drive gear (see the article - "Removing and installing the propeller shaft") and move it to the side.

Using a dynamometer, turn the drive pinion clockwise by the flange mounting nut and determine the torque of resistance to rotation of the pinion.

You can determine the torque in another way.

Tightly wind a strong thread around the flange neck several times and attach it to it dynamometer (or, more simply, hand scales).

The force at which the flange begins to rotate uniformly, multiplied by the radius of the neck, will give the value of the required moment.

Write down its value.

Having inserted two bolts into the flange holes and holding it with a mounting blade from turning, unscrew the nut with a 24 key

Remove the flange from the splines of the main gear pinion shaft.

If the flange sits tightly on the shaft splines, then use a hammer with a plastic striker to knock the flange off the splines

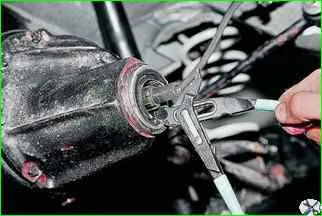

Use sliding pliers or a powerful screwdriver to remove the cuff

Lubricate the sealing surface of the seal with Litol-24 grease and lightly tap a hammer through a piece of pipe of a suitable diameter to press in the new seal.

Install the flange and washer on the pinion.

Holding the flange, tighten its fastening nut to a torque of 118-255 Nm (12-26 kgf.m), periodically checking the torque of resistance to rotation of the pinion (by turning the pinion clockwise with a dynamometer).

If the initially measured torque of resistance to rotation was not lower than 59.0 Nm (6 kgf.m), then the new torque should be greater than this value by 9.8-19.6 Nm (1-2 kgf.m).

If the initial torque was less than 59.0 Nm (6 kgf.m), then tighten the flange fastening nut until a torque of resistance to rotation of 59.0-88.0 Nm (6-9 kgf.m) is reached, not exceeding the tightening torque of 118-255 Nm (12-26 kgf.m).

If, when tightening the nut, the moment of resistance to rotation of the drive gear exceeds 88.0 Nm (9 kgf.m), which indicates an excessive preload of the bearings, replace the spacer sleeve of the gearbox and perform the adjustment again.

Further assembly and installation of units is carried out in the reverse order.