Valve seals or simply valve oil seals are changed during major engine repairs, as well as during cylinder head repairs

Valve seals are also subject to replacement when the engine overheats, in which case the elasticity of the valve seals is lost.

Increased oil consumption and increased smoke from the exhaust gases are a sign of replacing the valve seals.

Use a spark plug wrench to remove the spark plugs from the cylinder head.

Remove the cylinder head cover and look at "Cylinder head cover gasket replacement"

Turn the crankshaft until the mark on its pulley matches the mark on the camshaft drive cover.

Remove the camshaft housing and valve drive levers, look – «Removing the camshaft and valve drive levers VAZ-21214»

In this position of the crankshaft (pistons of the 1st and 4th cylinders are at TDC), we change the valve stem seals of the 1st and 4th cylinders.

Through the spark plug hole, we insert a rod of soft metal, about 8 mm in diameter, between the piston bottom and the valve plate (on which we are changing the stem seal). mm.

Install the valve spring compressor.

Put the valve spring compressor thrust pad against the valve plate and hook the engagement lever behind the nut screwed onto the camshaft bearing housing mounting stud.

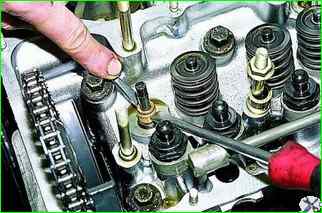

Compress the valve springs with the compressor and remove the valve springs with pliers (or tweezers).

Loosen the springs. Remove the valve plate

Remove the outer and inner springs as well as the upper and lower spring support washers

Use pliers to remove the oil deflector cap from the valve guide sleeve.

If you don't have pliers, use two screwdrivers to pry the oil deflector cap off.

Carry out the operation carefully so as not to damage the fragile guide sleeve.

After lubricating the working edge of the new oil deflector cap with engine oil, carefully put it on valve stem.

Using a high "12" head or a mandrel, press the cap onto the valve guide sleeve.

Assemble the valve mechanism in the reverse order.

Remove the rod from the spark plug hole.

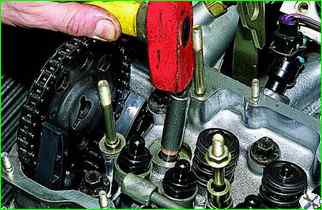

After replacing the oil deflector caps of the valves of the 1st and 4th cylinders, turn the crankshaft 180° (supporting the camshaft drive chain so that it does not get pinched) and change the valve caps of the 2nd and 3rd cylinders.

We assemble the valve timing mechanism in the reverse order.