We carry out the work in case of failure of one or more hydraulic supports of the valve drive levers

We remove the cylinder head cover, see the article - "Replacing the cylinder head cover gasket"

To check the condition of the hydraulic compensator, we insert a screwdriver between the edge of the camshaft bearing housing and the valve drive lever.

In this case, the camshaft cam should be facing the valve drive lever "with its back" (the valve is closed).

Leaning a screwdriver on the bearing housing, press through the lever on the hydraulic bearing.

In a normal state, the hydraulic bearing should be pressed with significant force.

If the force is small, the hydraulic bearing must be replaced.

To do this, remove the camshaft and valve drive levers, see - "Removing the camshaft and valve drive levers of the VAZ-21214 engine"

Using a 24 mm socket, unscrew the hydraulic bearing of the valve drive lever and remove it.

In the same way, we dismantle the hydraulic bearings of the levers of other valves.

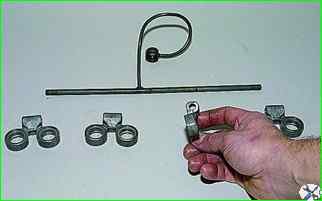

Remove the oil supply frame to the hydraulic mounts.

Move the oil supply bushing of the hydraulic mounts from the frame tube and remove it

Similarly, we remove three more oil supply bushings of the hydraulic bearings

The tightness of the connection of the frame tube and the oil supply bushings is ensured by rubber sealing rings installed in the bushings.

One sealing ring is installed in the outer bushings, two in the others.

To replace the sealing ring, pry it with a screwdriver and remove it from the bushing.

Before assembly, clean, rinse with gasoline and blow out with compressed air the channels in the tube and oil supply bushings of the frame.

Install new sealing rings in the bushings and lubricate them with engine oil.

Carefully, so as not to damage the rings, put the bushings on the tube.

Before screwing in the hydraulic bearings of the valve levers, use a syringe to pump out the oil from the hydraulic bearing seats in the cylinder head