Disconnect the intermediate shaft from the flange of the transfer case input shaft

Drain the oil from the transfer case and clean it from dirt.

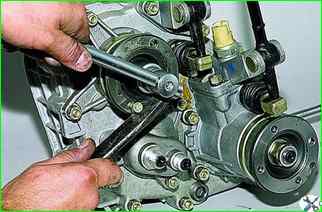

Loosen the nut of the input shaft flange.

Loosen the nuts of the other two flanges in the same way.

Remove the drive gear housing speedometer.

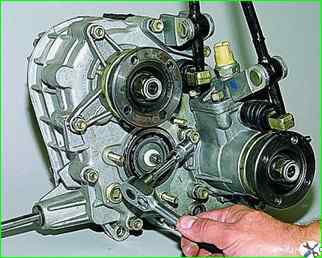

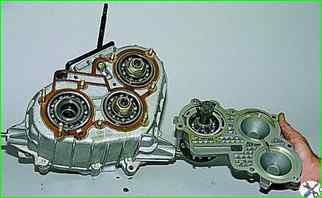

Using a 13 mm socket, unscrew the five nuts on the front axle drive housing.

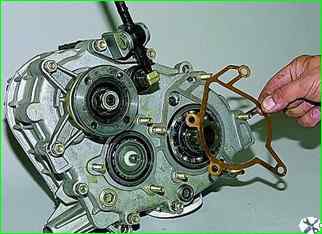

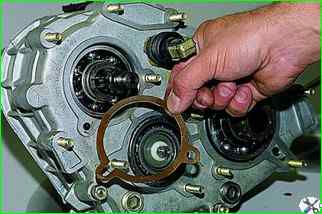

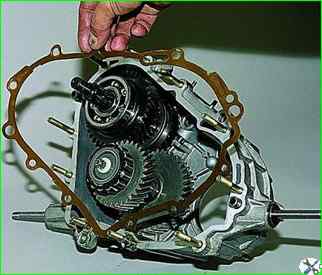

Prying the crankcase lugs with a screwdriver,

Removing it

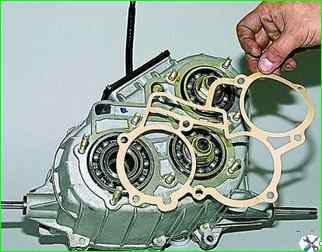

And remove the gasket.

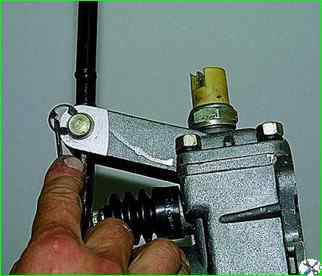

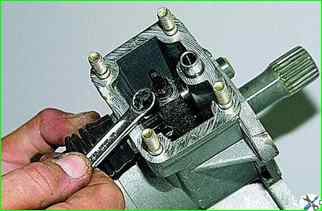

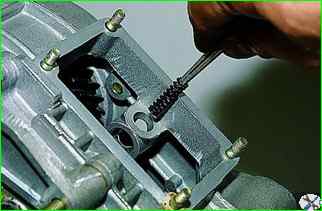

Prying off the lock washer with a screwdriver, we take out the axle of the differential lock lever (if difficult, knock it out with a punch made of soft metal).

Remove the differential lock lever and plastic axle bushings.

Remove the differential lock indicator light switch

Remove the lever spring from the differential lock fork rod

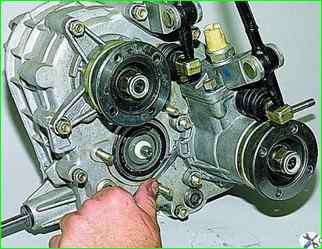

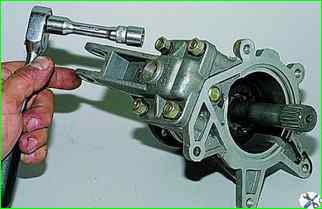

Using a 13 mm socket, unscrew the four nuts securing the front axle drive housing cover.

Remove the cover and gasket

Remove the spring and shake the retainer ball out of the crankcase socket

Using a 10 mm open-end wrench, loosen the locking bolt of the differential lock clutch fork.

We take out the bolt with the spring washer.

Pry off m screwdriver protective cover of the differential lock fork rod

We take out the rod with the cover.

Remove the plug

Remove the differential lock clutch.

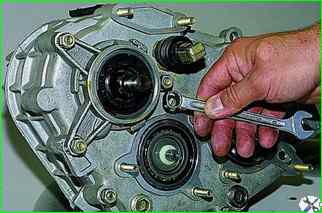

Unscrew the previously loosened flange mounting nut to the end and remove the washer

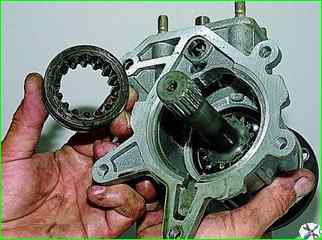

Removing the flange.

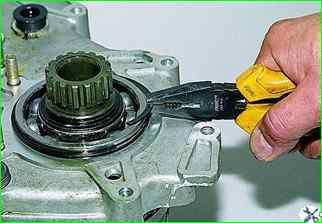

Using pliers, remove the retaining ring of the front axle drive shaft bearing.

Remove the shaft assembly from the crankcase

Remove the oil deflector and thrust ring from the front end of the shaft

Having hooked the outer ring of the bearing with a three-jaw puller, we press out the bearing.

Using a 13 mm socket, unscrew the eight nuts securing the rear cover to the transfer case housing.

Prying off the cover with a screwdriver, remove the rear axle drive shaft assembly and gasket.

Remove the rear axle drive shaft from the rear cover and disassemble it in the same way as the front crankcase shaft

Using a 13 mm wrench, unscrew the two nuts on the Weld the gear shift lever bracket to the transfer case housing and remove the gear shift bracket with the lever.

We disconnect the gear shift lever from the bracket in the same way as removing the differential lock lever.

After finally unscrewing the drive shaft flange nut, we remove the flange

Using a 13 mm wrench, unscrew the three nuts and remove the front bearing cover of the drive shaft.

The connection is sealed with a gasket.

Using a 10 mm wrench, unscrew the four nuts securing the hatch.

Remove the hatch and gasket

Remove the spring of the gearshift lever from the rod of the gear shift fork and move the rod cover

Inside the hatch, use a 10 mm open-end wrench to unscrew the bolt securing the fork to the rod.

To prevent the ball and the retainer spring from popping out, cover the hole with your finger and gradually pull the rod out with pliers

The retainer ball falls out through the side hole in the crankcase

We take out the retainer spring with tweezers

Pulling the rod further, we remove the gear shift clutch fork and the remote plastic sleeve.

We take out the rod.

The differential lock fork and gear shift fork rods are sealed with rubber.

We will show how to remove them using the example of the gear shift fork rod ring.

Prying it off with a screwdriver, we take out the rubber sealing ring.

We loosen the nuts of the rear bearings of the drive and intermediate shafts.

Using a 27 mm open-end wrench, unscrew one of the nuts, holding the shafts from turning by the other nut with a wrench or head of the same size

Remove the nut and washer

Insert the propeller shaft mounting bolts into the flange holes and put the flange on the splines of the transfer case drive shaft.

Unscrew the second nut, holding the shafts from turning with a mounting blade inserted between the bolts.

Remove the nut and washer.

Remove the drive shaft flange.

Remove the thrust ring of the front bearing of the drive shaft.

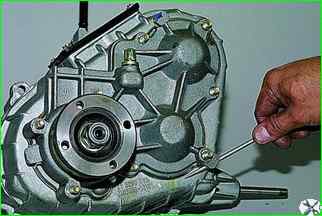

Using a 13 mm wrench, unscrew the three remaining nuts securing the front cover of the transfer case.

The remaining nuts of this cover were unscrewed when dismantling the front bearing cover of the input shaft, the front axle drive housing and the gearshift lever bracket.

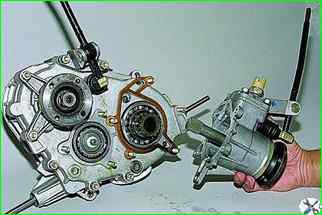

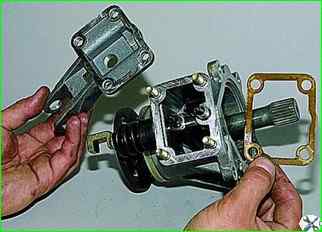

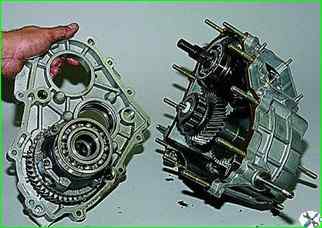

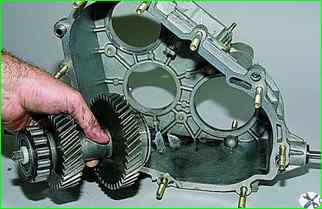

Remove the front cover of the transfer case with the differential.

Remove the gasket from the studs of the transfer case housing

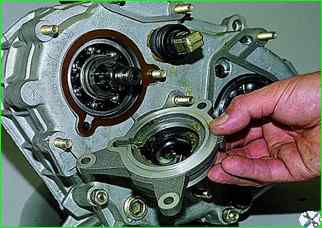

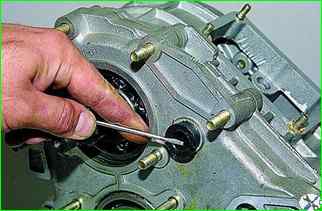

Using pliers, remove the installation ring of the front bearing of the differential housing

Disconnect the differential and the front cover of the transfer case.

Remove (or knock out with a soft metal punch) the outer ring of the front bearing of the intermediate shaft from the front cover socket.

Using pliers, we unclasp the retaining ring of the front bearing of the differential housing and remove it

Remove the spring washer.

Install a suitable stop for the puller screw into the hole in the front differential housing and Using a three-jaw puller, press off the front bearing.

If necessary, remove the rear bearing in the same way.

Apply marks to the front and rear differential housings so as not to disturb the unit's balance during assembly.

Having clamped the differential housing in a vice with soft metal jaw pads, use a 17 mm open-end wrench to unscrew the six bolts holding the driven gear, front and rear differential housings.

Disconnect the front and rear differential housings.

The driven gear remains on the front housing.

Knock it off the housing using a punch made of soft metal

Disconnecting the driven gear and the front differential housing

Remove the thrust washer from the front axle drive gear and take out the gear itself

Use pliers to loosen the retaining ring of the satellite axle and remove it

Remove the spring washer of the satellite shaft.

Hooking the pliers on the other retaining ring, take out the satellite shaft.

We take out the thrust washer and the satellite from the rear differential housing.

Having removed the second satellite and its washer, remove the rear axle drive gear.

For s removing the primary and intermediate shafts, use pliers to remove the mounting ring of the rear bearing of the drive shaft.

Similarly, dismantle the ring of the rear bearing of the intermediate shaft.

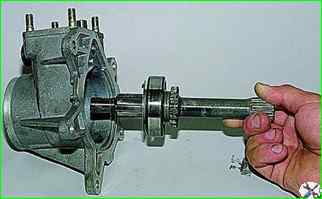

We take out the drive shaft and intermediate shaft from the crankcase.

We clamp the splined part of the drive shaft in a vice with soft metal jaw pads, and, hooking the puller paws onto the gear shift clutch, remove the rear bearing, bushing, low gear gear and clutch

Removing the clutch hub and top gear from the shaft

With a puller we press off the front bearing of the drive shaft.

Use a screwdriver to remove the rollers from the front bearing of the intermediate shaft and remove the separator.

Clamp the intermediate shaft in a vice with soft metal jaw pads.

Prying off the inner ring of the front bearing with two mounting blades, press it off and remove it.

Remove the intermediate shaft rear bearing in the same way as the drive shaft front bearing.

Assemble the transfer case in the reverse order.

When assembling the center differential, align the marks on its housings.

Install the spring washer on the satellite axle from the side of the blind hole on the axle end.

Using suitable pipe sections, press on the inner ring of the intermediate shaft front bearing, the front axle drive shaft bearing (the pipe rests on the inner ring) and the differential bearings.

In the same way, we press on the bearing of the rear axle drive shaft, the rear bearing of the intermediate shaft, the front and rear bearings of the drive shaft.

We install the drive and intermediate shafts in transfer case housing at the same time.

Lubricate all sealing gaskets with a thin layer of silicone sealant.

Having tightened the nuts of the rear bearings of the drive and intermediate shafts to the specified torque, lock the nuts by pressing their flanges into the grooves of the shaft tails.

After assembly, fill with oil.

Tightening torques of transfer case connections

Nut for fastening the suspension bracket to the axle - 26.5-32.3 Nm (2.7-3.3 kgf m)

Nut for fastening the suspension bracket to the body - 15.0-18.6 Nm (1.53-1.9 kgf m)

Nuts for fastening the transfer case housing cover, front axle drive housing, speedometer drive housing, control lever bracket - 14.7-24.5 Nm (1.5-2.5 kgf m)

Differential lock indicator light switch - 28.4-45 Nm (2.9-4.6 kgf m)

Fork to gear shift rod mounting bolt - 11.8-18.6 Nm (1.2-1.9 kgf m)

Fork to differential lock rod mounting bolt - 11.7-18.6 Nm (1.2-1.9 kgf m)

Driven gear mounting bolt - 66.6-82.3 Nm (6.8-8.4 kgf m)

Drive shaft rear bearing and intermediate shaft rear bearing mounting nut - 96-117.6 Nm (9.8-12.0 kgf m)

Nuts for fastening the flange of the cardan shaft to the drive shaft and to the drive shafts of the front and rear axles - 96-117.6 Nm (9.8-12.0 kgf m)