Repair ZIL-5301

The ZIL-5301 "Bychok" is a light-duty truck whose specifications vary depending on the model, but generally speaking, it features a 4.75-liter diesel engine (producing between 109 and 130 hp), a payload capacity of approximately 3–3.5 tons, and a top speed of 95 km/h.

Key features include rear-wheel drive, a five-speed manual transmission, and reinforced suspension with leaf springs.

- Steering malfunctions ZIL-5301

- How to repair liquid pump D-245E3

- Disassembling the coarse filter ZIL-5301

- ZIL-5301 springs assembly

- Assembly of the rear axle ZIL-5301

- Features of the ZIL-5301 oil system

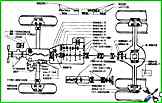

- Electrical diagram of ZIL-5301 harnesses

- Assembly, installation of gearbox ZIL-5301

- Clutch malfunctions ZIL-5301

- Brake system signaling device ZIL-5301