The signaling device is designed to warn the driver about damage to one of the circuits of the hydraulic drive brake system

It was installed only on cars with a drive split along the sides.

Disassembling the signaling device

To dismantle the signaling device, located on the bracket of the left wing mudguard, it is necessary to disconnect the pipelines from its housing, the wire of the signal lamp switch and unscrew the bolt holding the signaling device on the bracket.

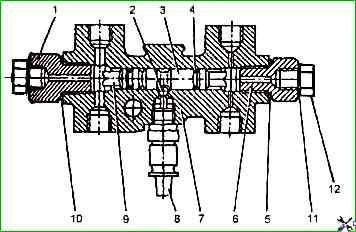

To disassemble the signaling device, it is necessary to unscrew the switch 8 (Fig. 1), remove the ball 2, then, having unscrewed the end fitting 1 and fitting 6, push out pistons 3 and 9.

When removing the pistons from the housing, care should be taken when pushing the pistons with a wooden mandrel so as not to damage the "mirror" of the housing 7.

When disassembling the signal device, replace the piston sealing rings.

Wash the parts and dry them with a jet of compressed air.

Replace damaged parts.

Assemble the signal device in the reverse order of disassembly, taking into account the following:

- - lubricate the cylinder mirror, pistons and sealing rings with fresh brake fluid;

- - install each piston on the corresponding side, preventing the sealing ring from passing through the hole for the ball, so as not to damage the sealing surface of the ring.

To check the signal device, do the following

Connect a hydraulic drive equipped with a pressure gauge to one of the chambers and plug the remaining openings of this chamber with plugs. The other chamber is connected to the atmosphere.

Connect the signal lamp, battery and signal device switch in series.

Gradually increase the pressure and record the value at which the lamp lights up.

The signal lamp should light up at a pressure of 1.1-2.1 MPa and the brake fluid should not leak from under the switch.

The reason for the reduced pressure that activates the signal device is insufficient tension of the cuffs due to wear of the housing "mirror" or the use of a low-quality cuff.

The reasons for the increased pressure that activates the signal device may be:

- - switch malfunction; scuffs on the "mirror" of the housing;

- - swelling of the cuffs;

- - poor cleaning (flushing) of the "mirror" of the housing.

After eliminating the above reasons, you should check the operation of the signaling device chamber again.

Repeat the operations with the second chamber (the first chamber communicates with the environment).

The signaling device is installed on the car in the reverse order of dismantling.

After installing the signaling device on the car and connecting the pipelines to it, you should bleed the hydraulic drive of the car.

Of course, the signaling device is a good thing, but as practice shows, many drivers remove it altogether and connect the tubes directly, as they say, "The simpler the system, the more reliable it is" the only thing you need to pay more attention to the presence of liquid in the tanks of the main cylinders.

If the liquid quickly decreases, then it is definitely necessary to look for the cause of the leak.