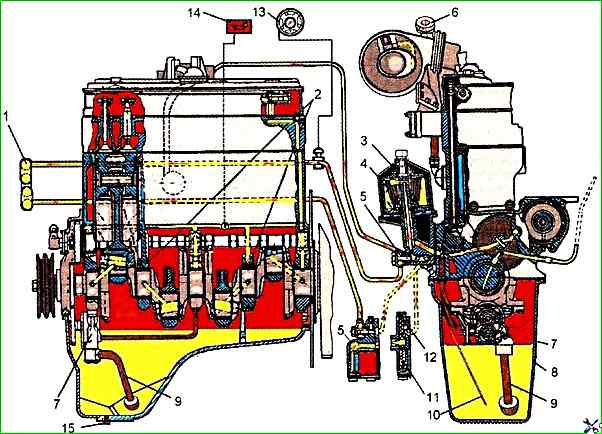

Diesel Lubrication System D-245

Diesel lubrication system is combined

Crankshaft and camshaft bearings, intermediate gear bushings and fuel pump drive gears, connecting rod bearing of the crankshaft of the brake air drive compressor, as well as the valve drive mechanism and the turbocharger shaft bearing are lubricated under pressure

Sleeves, pistons, piston pins, rods, tappets and cams of the camshaft are lubricated by splashing.

Oil pump 7 - gear, single-section, bolted to the cover of the first main bearing.

The pump delivers oil through the branch pipe and channels of the cylinder block to the centrifugal filter 3, where it is cleaned of foreign impurities, combustion products and wear.

From the centrifugal filter, the purified oil enters the radiator for cooling and through the oil supply pipe to the turbocharger shaft bearing.

From the oil radiator 1, the oil enters the diesel line.

In the housing of the centrifugal oil filter there are pressure-reducing 12, drain 11 and safety 5 valves.

When starting the diesel engine, unheated oil, due to the high resistance of the oil radiator, through The pressure-reducing (radiator) valve goes directly into the diesel line, bypassing the radiator.

The safety valve (centrifugal filter valve) serves to maintain the oil pressure in front of the filter rotor at 0.7 MPa.

When the pressure increases, some of the uncleaned oil is drained through the diesel crankcase.

The pressure-reducing and safety valves are not adjustable.

It is strictly forbidden to unscrew the plugs of the pressure-reducing and safety valves while the diesel is running.

The drain valve is adjusted to a pressure of 0.25-0.35 MPa and serves to maintain the required oil pressure in the main diesel line.

Excess oil is drained through the valve into the diesel crankcase.

From the main diesel line, oil flows through channels in the cylinder block to all main bearings of the crankshaft and camshafts.

From the main bearings, it goes through channels in the crankshaft to all the connecting rod bearings.

From the first main bearing, oil goes through special channels to the bushings of the intermediate gear and the fuel pump drive gear, as well as to the fuel pump.

The valve mechanism parts are lubricated with oil coming from the rear bearing of the camshaft through channels in the block, cylinder head, drilling in the fourth rocker arm stand into the internal cavity of the rocker arm axis and through a hole - to the rocker arm bushing, from which it goes through a channel to the adjusting screw and rod.

Oil comes to the compressor of the pneumatic brake drive from the main line through drillings in the cylinder block and a special oil line.

From the compressor, the oil drains into the crankcase diesel.

Main parameters of the lubrication system: