The engine removed from the vehicle for repair is disassembled completely or partially, depending on the nature of the damage

Complete disassembly of the engine is carried out in three stages: partial disassembly, disassembly of the engine into units and parts, and disassembly of the engine units into parts.

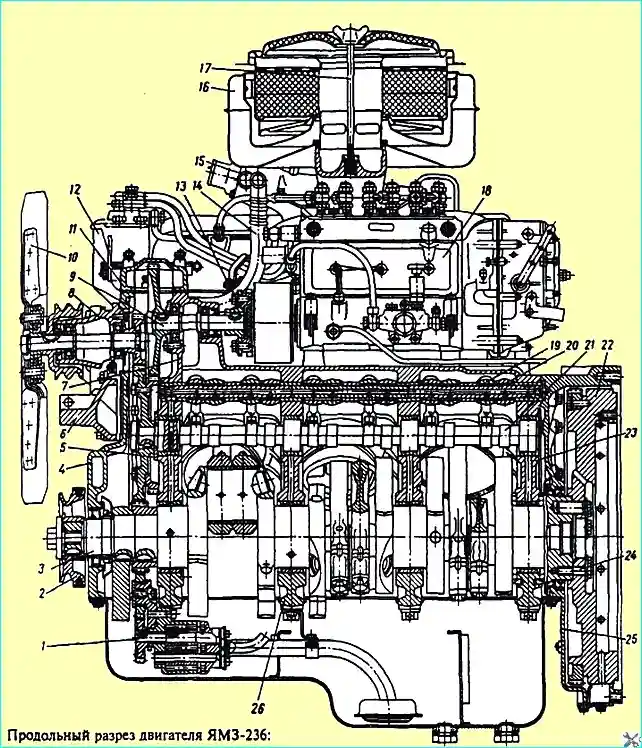

Disassembly of the YaMZ-236 and YaMZ-238 engines is carried out taking into account the design features.

Before disassembly, the engine is temporarily installed on a support, protecting the oil pan from damage, and the clutch housing mounting bolts are unscrewed.

Remove the gearbox together with the clutch housing, supporting it from below so as not to damage the driven clutch discs or the drive shaft of the gearbox, unscrew the bolts securing the clutch housing to the flywheel and remove the pressure plate with the housing assembly.

The bolts must be unscrewed gradually, loosening one by one, otherwise the last remaining bolts may be torn off by the force of the pressure springs.

Next, it is necessary to remove the driven disc.

For YAMZ-238K, YAMZ-2Z8, YAMZ-236K clutches, the middle driving and front driven discs must also be removed.

After this, it is necessary to unpin and unscrew the two tie bolts 2 (Fig. 1) securing the starter, remove the starter 3, the generator and the air brake compressor, unscrew the bolts, remove the impeller 10 (Fig. 2) of the fan, unscrew the rod 17 and remove the air filter 16, remove the four side plugs 23 (see Fig. 1) two on the right and left sides.

Having installed the engine on the stand (Fig. 3) and secured it with four clamps inserted into the holes of the water channels, it is necessary to:

- - remove the oil level indicator;

- - loosen the clamping clamp screws, remove the bypass 14 (Fig. 2) and connecting 15 tubes of the water thermostats;

- - remove the connecting pipe 15 (Fig. 1) of the intake manifolds and the fastening brackets of the high-pressure fuel pipes;

- - disconnect the pipes 12 and the fuel outlet pipe 11, having first released it from the clamp.

After removing the cylinder head covers 10, it is necessary to:

- - disconnect the injector drain pipes, unscrew the injector bracket fastening nuts and remove the injectors 9

- - remove the rocker arms 18 with the axles in assembly, take out the rods 5 pushers;

- - remove the heads of 8 cylinders and their gaskets.

Turning the engine on the stand with the flywheel housing down, remove the sump 27, oil pump 28 with differential valve 26 and pipes.

Unscrew the connecting rod bolts and remove the connecting rod caps, take out the pistons 4 assembled with the connecting rods 24.

Put the connecting rod caps on the corresponding connecting rods, guided by the marks, and screw them on with bolts.

Turn the engine to the working position and disconnect the low-pressure pipes, remove the fuel filter 12 (Fig. 2) fine cleaning;

- - remove the high-pressure fuel pump 18;

- - unscrew the half-coupling fastening nut on the shaft of the driven gear of the fuel pump drive and remove the half-coupling 13 together with the half-coupling washer and the press we remove the key from shaft 9;

- - remove the coarse and centrifugal oil filters (CMO) and flywheel 22.

To remove the flywheel, use two wrenches 1 (Fig. 3), which we screw into special holes with M12x1.75 thread until they stop against the crankshaft 2.

To avoid skewing of the flywheel 3, we screw in the wrenches simultaneously.

Then, remove the flywheel housing 25 (Fig. 2), the side of the oil pump pulley and the oil pump drive belt.

After unscrewing the crankshaft pulley mounting bolt, use a puller to remove the pulley 2 (Fig. 2) and extract the key from the crankshaft.

After this, remove the bracket 6 of the front engine mount and the upper cover 11 of the block, the fan drive housing, the cover 4 of the timing gears in assembly with water pump.

With the engine turned on the stand with the crankcase facing up, you should:

- - unpin and unscrew the bolts securing the main bearing caps, remove the caps 26, remove the crankshaft 3 from the cylinder block 23, using a special suspension (Fig. 5), protecting the shaft journals from damage;

- - remove the liners and thrust half rings from the supports and caps of the main bearings, put the caps of the main bearings in their places, guided by the marks;

- - unscrew the bolts securing the thrust flange 5 (see Fig. 2) of the camshaft, having first bent the lock washers, remove the camshaft 21 assembled with the gears;

- - press out, starting from the rear, the axle 20 of the tappets and remove the tappets 19 and the tappet spacer bushings.

With the engine turned on the stand with the crankcase down, unscrew the bolts securing the thrust flange of the driven gear of the fuel pump drive.

Having first bent the lock washers, remove the gear 7 assembled with the shaft 9 and bearings, and also all cylinder liners.

The liners are extracted from the cylinder block using the device shown in Fig. 6.

The device is inserted into the inner cavity of the sleeve, the shoulders of the thrust plate 1 are put on the lower end of the sleeve 2, the bushings 6 are put on the studs 5 of the cylinder block 3 and, screwing the nut onto the screw 4 by the handles 7, the sleeve is removed from the cylinder block.

When disassembling the cylinder head, unscrew the nuts securing the intake and exhaust pipes and the water distribution pipe, remove the pipes, water distribution pipe and gaskets.

While compressing the valve spring, remove the valve retaining crackers and the tapered sleeve of the plate, and then the plate, outer and inner springs.

The same sequence is performed for the remaining valves.

Then turn the cylinder head with the valve heads up, remove the valves from the guide bushings.

To disconnect the piston from the connecting rod, use pliers to remove the piston pin retaining rings and push it out with a mandrel.

Then remove the compression and oil scraper rings.

The camshaft is disassembled in the device shown in Fig. 8.

The camshaft is installed with its rear support cheek in the thrust bearing with its front journal in clamp 4 and secured by turning handle 3.

To protect the shaft from turning in the upper plate 1 there is a prismatic cutout, where the camshaft cam enters to remove the timing gear, it is necessary to unscrew the nut, having previously bent the whiskers of the locking washers of the nut faces, and unscrew the six bolts securing the fuel pump drive gear to the camshaft gear.

Then, having screwed the bolts 5 of the puller into two technological threaded holes in the body of the timing gear (Fig. 9), rotating the screw 2 with the stop 8 in the direction of the end of the shaft, we press the gear.

Disassembling the flywheel housing consists of pressing out the rear crankshaft oil seal.

The flywheel housing hatch cover and the piston top dead center indicator are not removed, and the need for their replacement is determined during the repair process.

After disassembling the engine, clean all mating surfaces from gasket residues and dirt and thoroughly wash the parts.