Adjusting the tension of the drive belts of the MAZ vehicle

The water pump, compressor and generator are driven by V-belts, the normal operation of these units depends on their reliable operation

Therefore, during daily maintenance of engines, protect the belts from oil and fuel, monitor their tension and adjust it.

Better check the tension of the belts during the first 50 hours of engine operation, since this is when they are most stretched.

The belt tension should always be normal, since both excessive and insufficient tension leads to their premature failure.

In addition, excessive tension of the water pump drive belt can cause the destruction of the pump bearings.

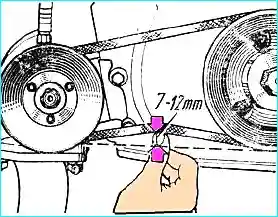

A normally tensioned water pump belt, when pressed in the middle of the long branch with a force of 40 N (4 kgf), bends by 7-12 mm (Fig. 1)

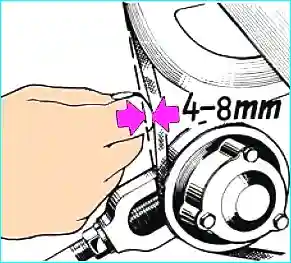

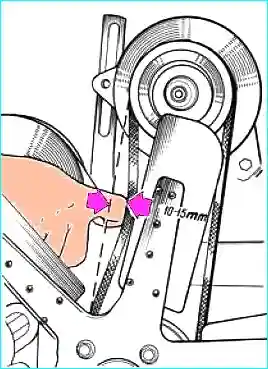

or 10-15 mm (Fig. 2), and the compressor belt - by 4 - 8 mm on the short branch (Fig. 3)

Check the alternator drive belt tension by pressing with a force of 40 N (4 kgf) on the middle of each belt branch (Fig. 4), while the alternator drive belts should sag by 10 - 15 mm.

If the belts sag more or less than specified, adjust their tension.

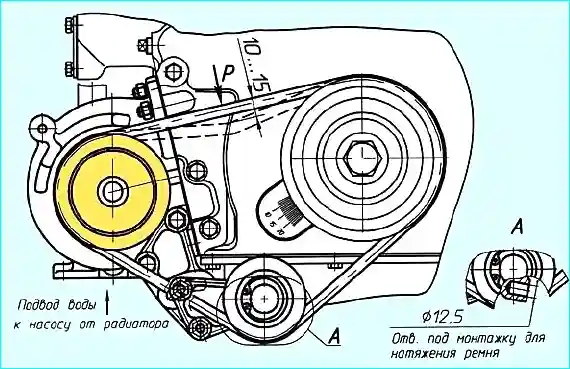

Adjust the tension of the water pump belt of the YaM3-2Z6NE, NE2, BE, BE2 engines (Fig. 1) with a tensioner, for which:

- - loosen the bolts securing the tensioner bracket lever;

- - use a Ø12 mm ratchet inserted into the hole in the tensioner bracket lever to tension the belt;

- - without loosening tension force tighten the tensioner bracket lever mounting bolts;

- - check the belt tension.

Adjust the tension of the water pump belt of the YaMZ-236N, B engines with shims (Fig. 5).

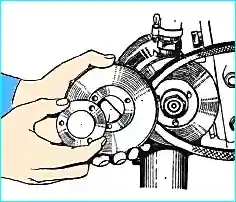

To adjust the belt, unscrew the pulley sidewall mounting nuts and remove one or two adjusting shims (Fig. 5).

Place the shims on the outer side of the sidewall and tighten the nuts sequentially in several steps, turning the pulley after tightening each nut.

Then check the correct belt tension.

When replacing the old belt, place all the shims between the hub and the removable pulley sidewall and adjust the belt tension as indicated above.

Adjust the compressor belt tension with a tensioner.

Before adjusting, unscrew the lock nut one turn, tensioner pulley axle mounting nut by half a turn and tensioner bolt nut by two turns.

Adjust the belt tension by turning the tensioner bolt.

After adjustment, tighten the axle mounting nut and lock nut to a torque of 120-150 Nm (12-15 kgfm) and the tensioner bolt nut to a torque of 10-20 Nm (1-2 kgfm). If the tightening torque is higher, the adjustment will be disrupted due to the pulley axle displacement.

Adjust the alternator drive belt tension by moving the alternator relative to its mounting axis.

Before adjustment, loosen the alternator mounting bolts, alternator bar mounting nut and alternator to bar mounting bolt.

After adjustment, securely fasten the alternator.

If the stretch is increased and at least one from the generator drive belts, replace both belts as a set to ensure uniform load on them.