Structurally, the cardan transmissions of all vehicle modifications are made according to a single scheme and differ only in the number of cardan shafts and their length

The small bases of MAZ-5335 vehicles and their modifications made it possible to implement a single-cardan scheme. Below are the main data of the cardan gears.

Main data

Length of cardan shafts (distance between the flanges of the hinges) of cars, mm:

- - MAZ-5335, MAZ516B - 1868

- - MAZ-504V, MAZ5429, MAZ-5430, MAZ-5549 - 1320

Dimensions of cardan shaft pipes, mm:

- - outer diameter - 89±0.32

- - wall thickness - 3.5±0.16

- - diameter of crosspiece necks, mm - 33.65-0.015

- - Type of needle bearing universal joints of the cardan shaft GPZ-804707K3S10

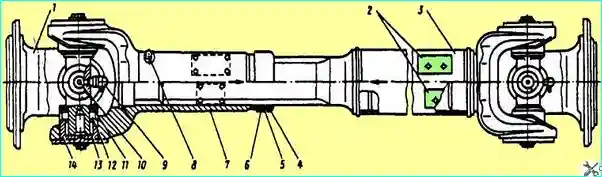

Fig. 1. Universal joint: 1 - flange-yoke; 2 - balancing plates; 3 - shaft; 4. oil seal ring; 5 - oil seal; 6 - oil seal cage; 7 - sliding fork; 8 - fork oiler; 9 - universal joint oiler; 10 - universal joint; 11 - mechanical seal; 12 - needle bearing oil seals; 13 - needle bearing; 14 - bearing cap

The MAZ-5335 MAZ-516B vehicles have longer cardan shafts than other modifications. The cardan joints of all cardan transmissions of MAZ vehicles are completely unified.

The MAZ-64227 vehicles have a cardan transmission consisting of two cardan shafts: a drive to the middle and rear axles. MAZ-54322 has one cardan shaft to the rear axle.

Cardan transmission maintenance consists of lubricating operations, as well as checking the condition of the cardan shaft flange fastenings and needle bearing caps.

Possible cardan transmission faults and methods for eliminating them by maintenance and repair operations are given in the table.

Cardan transmission lubrication is performed in strict accordance with the frequency of lubrication operations and the lubricant used for bearings, crosspieces, splined connections.

Checking the fastening of the cardan shaft flanges is performed on the vehicle with the parking brake released.

The gearshift lever is set to neutral. The vehicle must be braked with wheel stops.

If, when rocking the cardan shaft forks, a loosening of the secondary shaft flanges of the gearbox or the drive pinion of the rear axle reduction gear is detected, it is necessary to disconnect the corresponding end of the cardan shaft, unpin the flange fastening nut, and then tighten it to the limit and cotter pin it.

All the fastening bolts of the cardan shaft flanges must also be carefully tightened to a torque of 44-56 Nm (4.4-5.6 kgf.m).

If a torque wrench is not available, they must be tightened to the limit. Replacing the flange mounting bolts installed during factory assembly with non-heat-treated bolts is not permitted.

Gaps between the crosspiece 10 and the needle bearings 13 (see Fig. 1) are eliminated by tightening the bolts securing the bearings.

Faults that arose during operation and the method of elimination

Increased noise, clearly audible when coasting

- Lack of lubrication in splined connection - Lubricate the splined connection

- Loose fork flange mounting bolts - Tighten bolts

- Worn splined connection parts - Replace propeller shaft

- Worn intermediate support bearing - Replace bearing

Vibration of propeller shaft

- Bent or twisted propeller shaft tube - Replace propeller shaft

- Incorrect connection of sliding fork to splined end of shaft - Install splined end of shaft into sliding fork, aligning arrows

- Increased wear of joint parts - Replace crosspiece

- Breaking off balance plates - Replace shaft or balance

When disassembling the cardan shaft with a sliding fork (see Fig. 1), do the following:

- - bend the tabs of the locking plate from the bolt faces, unscrew the bolts and remove the locking plates and bearing caps 14 from the ends of the fork cheeks;

- - remove the needle bearings 13 from the holes of the flange-fork 1 and the sliding fork 7. To press out the bearings from the flange-fork and from the fork, it is necessary to use a special device.

Do not use a hammer, as this leads to a violation of the alignment of the holes for the bearings in the joint forks.

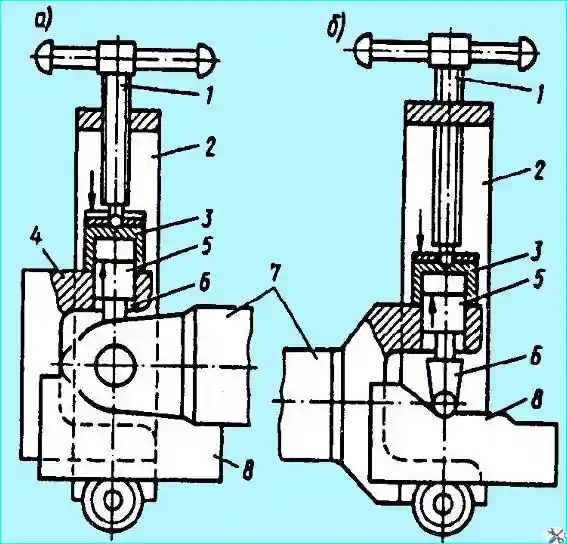

When pressing out the bearings, install the fork 7 of the cardan shaft on the support prism (Fig. 2). and press the bearings out of the fork flange (see Fig2, a), then press the end seals and remove the flange-yoke 4 and after that the pins of the crosspiece 6 are installed in special holes of the support prism and the bearings are pressed out of the fork 7 of the cardan shaft (see Fig. 2, b);

- - remove the flange-yoke 1 from the pins of the crosspiece 10 (see Fig. 1) and remove the crosspiece 10 from the holes of the sliding fork, unscrew the oiler 9 from the crosspiece 10.

Pressing out bearings from the flange-yoke (a) and from the shaft fork (b): 1 - screw; 2 - sliding posts; 3 - cup; 4 - flange-yoke of the cardan shaft; 5 - bearing; 6 - crosspiece; 7 - cardan shaft fork; 8 - support prism

The cardan shaft is disassembled in the same sequence from the side of the connection with the sliding fork.

The subsequent disassembly is carried out in the following order:

- - unscrew the oiler 8 from the sliding fork 7;

- - unscrew the collar 6 of the oil seal and remove the sliding fork 7 from the splined end of the cardan shaft;

- - remove the sealing ring 4 of the oil seal from the collar 6 of the oil seal and remove the collar 6 from the splined end of the shaft.

The flange-fork, sliding fork and crosspiece of the cardan shaft are subject to repair in the cardan transmission.

The flange-fork of the cardan shaft is made of steel 40 and heat-treated to a hardness of HB 229-269.

The main defects, in the presence of which the flange-yoke is subject to restoration, are: wear of the holes for bearings and flange mounting bolts. The flange-yoke is rejected if the distance between the cheeks is less than 134.96 mm or more than 135.09 mm.

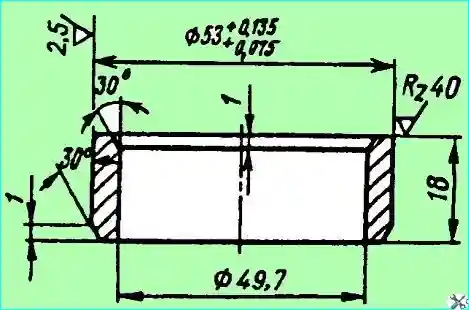

Fig. Repair bushing for cardan fork holes for needle bearings

When the bearing holes wear out to a diameter of more than 50.05 mm, they are restored by installing repair bushings.

The flange-yoke with a 132 mm landing collar is installed in a device fixed on the spindle of a lathe, secured with a clamp and two holes are bored in a line to a diameter of 53+0.06 mm.

Then repair bushings (Fig. 3), made of 20 steel, are pressed into the bored holes, welded to the fork at four points on the inside with an electrode UONI-13/45 Ø 3 mm.

Then the bushings are filed flush with the main surface of the part from the side of the inner end, the holes are bored and reamed in bushings in line up to Ø 50+0.027 mm.

The axis of the surfaces of the holes for the bearings of the surface must intersect the axis of the mounting flange with an accuracy of 0.1 mm and the misalignment of the surfaces of the holes for the bearings is allowed to be no more than 0.025 mm.

If the wear is more than 10.5 mm, the holes for the fastening bolts are drilled to Ø 12 mm, countersunk at an angle of 90 ° to a depth of 8 mm and welded with an electrode UONI-13/55 Ø 4 mm.

Then install the flange in the fixture on the lathe, based on the holes for the bearings, and grind the surface of the flange on both sides from the metal build-up flush with the main surface.

After this, install the flange in the jig, based on the surface of the mounting flange, drill eight holes Ø 10+0.3+0.1 mm and countersink them on both sides (chamfer 0.5 x 90°). The holes must be evenly spaced around the circumference with an accuracy of 0.12 mm.

The sliding fork of the cardan shaft is made of steel 40 and heat-treated to a hardness of HB 229-269. The fork is restored when the holes for the bearings, spline grooves along the width and outer diameter are worn out, and when the thread for the gland race is damaged.

The holes for the bearings are restored in the same way as in the flange-fork. The axes of the surfaces of the holes for bearings and the spline surface must be perpendicular with an accuracy of 0.1 mm over a length of 100 mm and intersect with an accuracy of 0.1 mm.

Misalignment of the surfaces of the holes for bearings is allowed to be no more than 0.025 mm.

If the wear on the outer diameter is more than 65.05 mm or on the width to a size of more than 5.10 mm, the spline grooves are restored by compression with simultaneous cutting of the thread for the nut.

The crosspiece of the cardan shaft is made of 18KhGT steel and cemented to a depth of 1.6-1.9 mm with subsequent hardening to a hardness of HRC58-64.

The main defect for which the crosspiece is subject to restoration is wear of the studs to a size of less than 33.62 mm.

If there is a deviation distances between the ends of opposite tenons to a size of less than 126.91 mm or more than 127.05 mm, the crosspiece is rejected.

Worn tenons of the crosspiece are restored to a diameter of 36.5 by vibratory arc surfacing of OVS wires with a diameter of 1.6 mm with cooling, followed by grinding to a diameter of 33.65-0.015-0.030 mm and a rough 0.63.

The pins must lie in the same plane with a deviation of no more than 0.3 mm.

The cardan shaft is assembled in the following sequence:

- screw the safety valve and angular oiler 9 into the crosspiece 10 (Fig. 1), the inclined part of which must be located between the pins of the crosspiece at an angle of 45± 5° and protrude from the crosspiece by no more than 33 mm. the size corresponds to the distance of the end of the oiler to the axis of the crosspiece tenons;

- - insert the assembled crosspiece 10 with tenons into the holes of the sliding fork 7 and install the flange-yoke 1 on the free tenons of the crosspiece. In this case, the crosspiece is positioned so that the oiler is facing the sliding fork.

- - press the end seals 11 onto the tires of the crosspiece 10 through the holes for the bearings in the forks, place plastic grease No. 158 in the cavity between the working edges of the end seal and the needle bearing in an amount of (10±1) g in each bearing;

- - press the needle bearings 13 into the holes of the fork 1 and the sliding fork 7. The assembly of the hinge with the bearings is carried out only with the use of a hand press.

It is permissible to unscrew the oiler from the crosspiece to facilitate the assembly of the joints when pressing in the bearings to allow excess grease to escape, and the oiler should be screwed in after the joint is fully assembled;

- - install support and locking plates on the ends of the fork cheeks, secure each cover and plates with bolts that must be tightened to a torque of 14-17 Nm (1.4-1.7 kgf/m) and locked by bending one of the ears of the locking plate to the edge of the head of each bolt;

- - similarly install the flange-yoke from the second end of the cardan shaft 3;

- - install the collar 6 of the oil seal 5 of the sliding fork 7 from the splined end, the ring 4 of the oil seal, placing it in the collar, and insert the rubber seal into the collar ring 4;

- - install sliding fork 7 on the splined end of the cardan shaft so that the axes of the holes in the sliding fork and in the fork on shaft 3 are in the same plane, a deviation of the axes of these holes by an angle of no more than 2° is allowed.

In this case, the arrows on the sliding fork and the cardan shaft pipe must be aligned;

- - screw the collar 6 of the oil seal onto the sliding fork 7, screw the oiler 8 into the fork and lubricate the splined connection through it with USSA or Litol-24 grease until it is squeezed out of the hole in the plug of the sliding fork;

- - punch the collar 6 of the sliding fork oil seal in two places located around the circumference;

- - check the swing angle cardans from the central axis in each direction, which should be at least 24°;

- - perform dynamic balancing of the assembled cardan shaft.

- - the imbalance should not exceed 65 g/cm. The imbalance is eliminated by welding plates 2, bent along the outer diameter of the cardan shaft, and turning the sliding fork by 180°.