The gearbox assembly is performed in three stages: assembly of the drive shaft and drive shaft bearing cap units, intermediate and driven shafts, gearbox top cover, remote gear shift mechanism, oil pump, general gearbox assembly and testing

The drive shaft and drive shaft bearing cap are assembled in the following sequence:

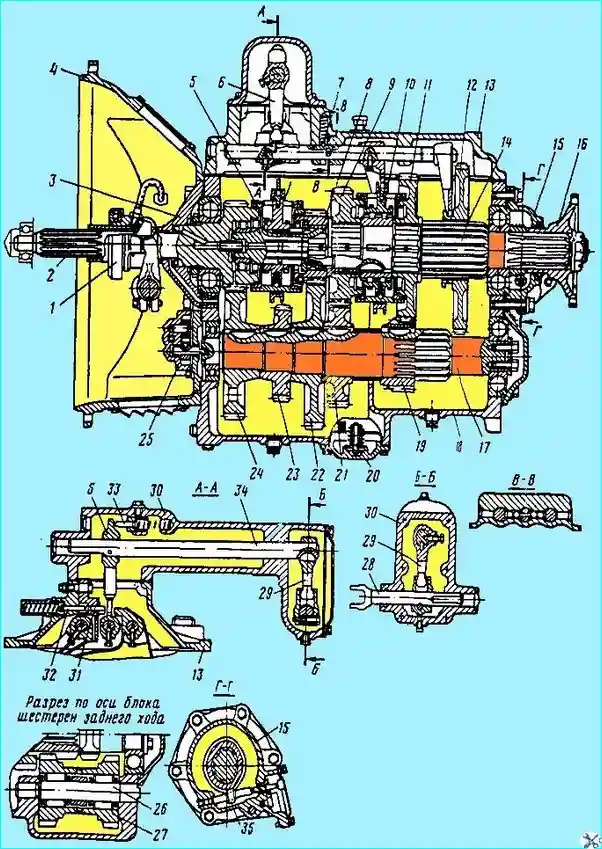

Fig. 1. Gearbox: 1 - clutch release sleeve; 2 - drive shaft; 3 - drive shaft bearing cap; 4 - clutch housing; 5 - fourth and fifth gear synchronizer; 6 - gear shift lever; 7 - retainer with spring; 8 - fifth gear pinion of driven shaft; 9 - third gear pinion of driven shaft; 10 - synchronizer of second and third gears; 11 - second gear pinion of driven shaft; 12 - first gear and reverse gear pinion of driven shaft; 13 - upper gearbox cover with rod and forks; 14 - driven shaft; 27, 15 - driven shaft bearing cover; 16 - flange; 17 - intermediate shaft with first gear pinion; 18 - gear map; 19 - second gear pinion of intermediate shaft; 20 - oil pump intake with magnet; 21 - third gear pinion of intermediate shaft; 22 - fifth gear pinion of intermediate shaft; 23 - power take-off pinion; 24 - intermediate shaft drive pinion; 25 - oil pump; 26 - reverse gear block axis; 27 - reverse gear block; 28 - rod; 29 - intermediate lever; 30 - crankcase; 31 - first gear and reverse gear shift linkage; 32 - reverse code engagement fuse with spring; 33 - pin; 34 - shaft; 35 - speedometer gear worm

- - install the drive shaft (see Fig. 1) with the toothed rim on the support and press the rear ball bearing onto the shaft journal until it stops, having first installed the retaining ring in the groove of the outer race;

- - screw the ring nut onto the threaded shaft journal and tighten it until it stops. The edge of the nut is punched into the groove of the shaft;

- - install the cover 3 of the bearing of the drive shaft with the seat under the oil seal upwards and press the oil seal into the seat until it stops, having previously lubricated the outer surface of the oil seal with nitro enamel.

The intermediate and driven shafts are wiped before assembly, and the mating surfaces are lubricated with oil.

The intermediate shaft is assembled in the following order:

- - install shaft 17 (see Fig. 1) with the toothed ring on the table of the hydraulic press, press the key into the groove of the shaft and press gear 19 of the second gear onto the shaft until it stops against the toothed ring of the shaft. The hub of gear 19 should be facing away from the toothed ring;

- - put the spacer sleeve of the second and third gear gears on the shaft, press the segment key into the shaft groove and press gear 21 of the third gear until it stops with the short hub towards the spacer sleeve;

- - press the key into the shaft groove and press gear 22 of the fifth gear until it stops with the short hub towards gear 21 of the third gear;

- - press the key into the shaft groove and press gear 23 of the power take-off with the long hub from gear 22 of the fifth gear until it stops;

- - press the key into the shaft groove and press gear 24 until it stops with the long hub towards gear 23 power take-off;

- - install the front thrust ring in the shaft groove, press the front roller bearing onto the shaft until it stops and install the thrust ring of the bearing in the shaft groove.

Assemble the driven shaft in the following sequence:

- - install shaft 14 (see Fig. 1) with the threaded end down;

- - install the thrust washer on the shaft until it stops against the end face of the splined surface and gear 11 of the second gear with the toothed rim from the thrust washer. The gear on the shaft should rotate easily without jamming;

- - press the keys into the shaft grooves and press the spacer sleeve of the second and third gears onto the shaft until it stops with the large end towards the gear II of the second gear;

- - install the synchronizer 10 of the second and third gears assembled with the carriage with the short hub towards the gear 11 of the second gear onto the splines of the spacer sleeve;

- - press the sleeve of the gear 9 of the third gear onto the shaft until it stops against the spacer sleeve, aligning the cutout in the sleeve with the key of the spacer sleeve, and install gear 9 on the sleeve with the straight-toothed crown towards the synchronizer 10. The gear on the shaft should rotate easily without jamming;

- - check the longitudinal movement of the cage of the conical rings of the synchronizer 10, which should be within 3-5 mm. The engagement of the synchronizer carriage teeth with the gear teeth should be easy, without jamming;

- - press the fifth gear gear 8 sleeve onto the shaft until it stops with the shoulder towards the third gear gear 9 and, at the same time, aligning the pin of the sleeve with the groove of the shaft, install gear 8 on the sleeve with the straight-toothed crown away from the flange of the sleeve.

The gear should rotate on the shaft easily, without jamming;

- - install the thrust washer of gear 8 of the fifth gear, rotating it until the projections of the washer align with the splines of the shaft, and press in the locking key.

The gap between the sleeve of the fifth gear gear and the thrust washer should be within 0.02-0.1 mm, which is ensured by selecting the thickness of the thrust washer before installing the fifth gear gear.

Thrust washers are made in three thickness sizes: 7-0.58, 7.15-0.58 and 7.3-0.58 mm;

- - install synchronizer 5 of fourth and fifth gears on splines of driven shaft 14 with straight-toothed rim of carriage of smaller diameter towards fifth gear pinion;

- - press front roller bearing onto front journal of shaft until it stops and install thrust spring ring in groove on front journal;

- - press oil seal into hole of cover 15 of driven shaft flush with inner end of hole. Before pressing in the seal, the seating surface of the hole in the cover is lubricated with nitro enamel.

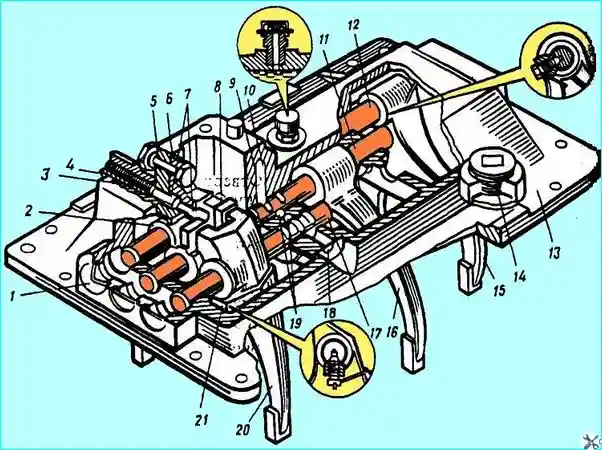

The upper cover of the gearbox is assembled in the following sequence:

- - insert spring 19 and locking ball 18 into the seat of cover 1, insert rod 21 into the holes of the cover while simultaneously installing head 11 and fork 3 for engaging reverse gear on the rod.

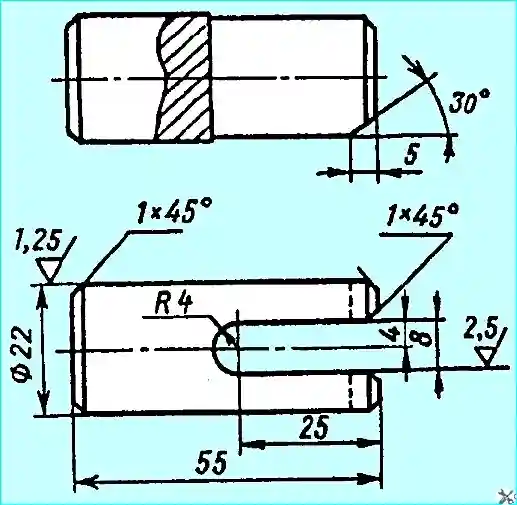

When installing the rod, use a mandrel (Fig. 3). Align the threaded holes in the head and fork with the holes in the rod and secure them with a locking screw, which is secured with a cotter pin;

Fig. 2. Gearbox cover: 1, 18 - plug; 2 - head of the reverse gear fork rod; 3 - safety spring; 4 - spring cup; 3 - linkage axis; 6 - linkage: 7 - reverse gear safety devices; 8 - head of the 1st and 2nd gear fork rod; 9 - retainer ball; 10 - retainer spring, 11 - 1st and 2nd gear fork rod; 12 - reverse gear fork rod; 13 - top cover; 14 - plug: 15 - reverse gear fork; 16 - 1st and 2nd gear shift fork; 17 - 3rd and 4th gear shift fork rod; 19 - rod lock ball; 20 - 3rd and 4th gear shift fork; 21 - lock bolt

- - install rod 5 of the third and fourth gear shift fork into cover 1 (Fig. 2) and simultaneously install fork 8 on the rod.

Align the threaded hole in the fork with the hole in the rod and secure the fork with a lock screw 9, which is secured with cotter wire;

- - insert two balls 7 of the gear shift rod lock into the channels of the cover under rod 21 of the reverse gear fork and under rod 5 of the third and fourth gear shift fork;

- - set rods 21 and 5 to the neutral position;

- - insert the rod lock pin into the rod hole, which should move freely in the hole, and the assembled rod with head 1, fork installed on it. 4 first and second gear shifts are inserted into the cover.

Align the threaded holes of the head and fork with the holes in the rods and install a locking screw in them, which is secured with cotter wire;

- - insert plugs 10 into the holes in the cover under the rods.

- - install the plugs on nitro enamel;

- - install the leash 15 for engaging the reverse gear on the cover and secure it with an axis 14, onto the threaded end of which a nut is screwed

- - insert the safety spring into the cup 13 and screw the cup into the cover;

- - screw the oil filler plug 2 and the breather assembly into the cover 1

The remote gear shift mechanism is assembled in such a way sequences:

- - insert pin 33 (see Fig. 1) into the bushing, install a spring on the head of the pin in the bushing, and then install the assembled unit with the bushing into the socket of the crankcase 30, aligning the hole in the bushing with the threaded hole in the crankcase, and screw in the lock bolt with the spring washer;

- - screw the oil filler and drain plugs into the crankcase 30;

- - insert a segment key into the groove of the shaft 34, put the intermediate gearshift lever 29 on the shaft, having previously aligned the groove in the lever with the key and the threaded hole with the hole in the shaft, screw in the set screw and secure it with cotter wire;

- - install the assembled shaft 34 into the crankcase 30 from the side hatch of the crankcase cover;

Fig. 3. Mandrel for installing the gear shift fork rods

- - insert a key into the groove of the free end of the shaft and put it on its end gear shift lever 6, aligning the threaded hole in the lever with the hole in the shaft, screw in the set screw and secure it with a cotter wire like the intermediate lever 29;

- - put the head of the rod 28 on the ball surface of the intermediate lever 29, insert the sealing ring of the rod 28 into the groove of the crankcase and insert the rod 28 into the crankcase from the side of the sealing ring with a recess for the bolt for fastening the head of the rod from the intermediate lever 29, simultaneously putting the head on the rod so that the threaded hole in it is located from the hatch;

- - align the hole in the head with the recess on the rod 28 and screw in the bolt for fastening the head with a lock washer;

- - lubricate both sides of the crankcase cover gasket with sealing paste, install it on the crankcase hatch, aligning the holes for the bolts, apply onto the gasket, the cover of the mechanism housing and screw the bolts with spring washers into the aligned holes.

The oil pump is assembled in the following sequence:

- - a segment key is pressed into the groove of the drive gear shaft and the shaft with the key is pressed into the drive gear, maintaining the size of (25.5±0.5) mm from the end of the gear to the end of the shaft on the shank side;

- - the driven gear assembled with the bronze bushing is put on the axle and the shaft assembled with the drive gear is inserted into the bushing at the base;

- - the pump body gasket is installed on the base, having previously degreased it with white spirit and lubricated it on both sides with a sealing paste;

- - the pump body assembled with the gears is installed on base, aligning the holes of the housing, gasket and base, and screw in the bolts with spring washers;

- - check the ease of rotation of the gears, which should rotate easily by hand and without jamming;

- - insert a ball and a spring into the pump housing socket and screw in the bypass valve plug until it stops;

- - cotter the fastening bolts and the valve plug with a wire with a diameter of 1.2 mm;

- - test the assembled pump on a stand with Dp - 11 oil at a temperature of (50 ± 5) ° C at a drive shaft speed of 1100 min for at least 3 min:

During testing, the oil pressure at the outlet should be within 0.7-0.12 MPa (0.7-1.2 kgf / cm²) and the capacity - at least 7 l / min at back pressure 0.07-0.12 MPa (0.7-1.2 kgf/cm²). Oil leakage through the connections is not allowed.

The general assembly of the gearbox is performed in the following sequence:

- - install the intake screen with the gasket assembly in the lower hatch of the crankcase 18 (see Fig. 1) of the gearbox, place the intake cover 20 with the magnet assembly on the screen and screw the bolts with spring washers into the aligned holes, tightening them evenly;

- - install the gaskets and covers on the side hatches of the gearbox crankcase and screw the bolts into the aligned holes. The hatch cover gaskets and threaded holes for the bolts are lubricated with a sealing paste before installation;

- - blow out the oil channels and the internal cavity of the gearbox housing with compressed air, screw the oil drain plugs and the oil level control plug into the housing, having previously lubricated the threaded holes with a sealing paste;

- - install the intermediate shaft assembly 17 in the gearbox housing with the bearing in the front seat, install the retaining ring in the groove of the outer race of the ball bearing, press the rear ball bearing onto the end of the intermediate shaft and into the hole in the housing at the same time, install a thrust washer on the end of the intermediate shaft, screw the bolts into the aligned holes, tightening them until they stop;

- - assemble the block 27 of the reverse gears with roller bearings and an intermediate sleeve, having previously lubricated the roller bearings consistent grease TSIA-TIM-201;

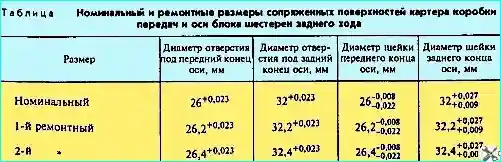

- - install the reverse gear block in the gearbox housing 18 with the small toothed rim toward the rear end of the housing, press the axle 26 of the gear block into the holes of the housing of the nominal or repair size (see table) so that the chamfer on the end of the axle faces the rear bearing of the intermediate shaft;

- - install the cover of the rear bearing of the intermediate shaft on the end of the gearbox housing with the protrusion toward the chamfer on the axle of the gear block and screw the bolts with spring washers into the aligned holes, tightening them evenly;

- - check the rotation of the reverse gear block and the intermediate shaft by supplying compressed air under a pressure of 0.5-0.7 MPa (5-7 kgf/cm²) to the teeth of the gear block. Knocks, grinding and uneven noise are not allowed;

- - install gear 12 of the first gear and reverse gear on the splines of the driven shaft 14 and check the ease of its movement along the splines, remove the gear from the shaft and place it in the gearbox housing 18, blow out the driven shaft assembly with compressed air and smoothly install it in the gearbox housing, simultaneously installing the first gear and reverse gear on it;

- - blow out the channels of the drive shaft with compressed air and install the drive shaft 2 assembled with the bearing in the hole of the crankcase 18, aligning the oil drain pipe with the hole in the driven shaft;

- install the retaining ring in the groove of the outer race of the rear ball bearing of the driven shaft 14 and press the bearing onto the rear end of the driven shaft into the hole of the gearbox crankcase 18 at the same time;

- check the ease of rotation of the shafts by hand. The shafts should rotate easily, without jamming when the synchronizers and gear 12 are in the first gear and reverse gear position;

- press on the drive pinion speedometer on the rear end of the driven shaft 14, install the gasket and cover 15 of the rear bearing of the driven shaft, having previously lubricated the working surface of the seal in the cover with TSIA-TIM-201 consistent grease, screwing a bolt with spring washers into the aligned holes and tightening them evenly until they stop;

- press on the flange 16 of the cardan shaft until it stops, put a disc washer on the splined end of the driven shaft, screw on and tighten the nut until the slot in the nut aligns with the hole in the shaft and insert the cotter pin.

- lubricate the screw groove and the working surface of the seal in the cover 3 of the bearing of the drive shaft 2 with TSIA-TIM-201 consistent grease, the sealing gasket of the cover on both sides and the threaded holes in the crankcase for the cover fastening bolts - sealing paste "Sealant";

- apply a gasket to the cover flange, aligning the holes for the bolts, install cover 3 on drive shaft 2, aligning the oil drain channel in the cover with the throttle sleeve in gearbox housing 18, screw the bolts into the aligned holes, tightening them until they stop, having previously placed flat washers under them, and lock the bolts in pairs with cotter wire with a diameter of 1.2 mm;

- lubricate the sealing gasket of oil pump 25 on both sides and the threaded holes in gearbox housing 18 for the oil pump mounting bolts with sealing paste "Sealant";

- apply a gasket to the base of oil pump 25, aligning the holes for the bolts, install the pump assembly on gearbox housing 18, aligning the position of the protrusion of the pinion shaft shank with groove in the intermediate shaft 17 and the cut part of the base directed towards the cover 3 of the bearing of the drive shaft, and screw the bolts with flat washers placed under them into the aligned holes, which are locked in pairs;

- check the rotation of the gearbox shafts by hand, which should rotate easily, without jamming;

- install the upper and lower covers on the hatches of the housing 4 of the clutch and secure them with bolts with spring washers placed under them;

- lubricate the threaded holes in the housing 18 of the gearbox under the bolts for fastening the housing 4 of the clutch with the sealing paste "Sealant";

- install the assembled housing 4 of the clutch on the end of the gearbox, screw the bolts with spring washers placed under them into the aligned holes of the clutch housing and the gearbox and lock them in pairs with a cotter pin-wire with a diameter of 1.6 mm;

- insert the clutch release fork shaft into the 4 clutch housing bushings so that the splined end of the shaft is on the left when looking at the gearbox from the side of the Cardan shaft flange, check the ease of rotation of the shaft by hand, insert a key into the shaft groove, pull the shaft out of one bushing, install the clutch release fork on it with the machined surfaces forward, screw the tie bolt with washers into the fork hole, set the fork symmetrically to the pipe of the cover 3 of the drive shaft bearing and tighten the tie bolt finally;

- press the bearing onto the neck of the clutch release coupling 1 until it stops. After pressing, the inner ring and outer race of the bearing should rotate freely by hand;

- install the clutch 1 assembly on the cover 3 of the drive shaft bearing, check the ease of movement of the coupling along the cover of the drive shaft, connect the coupling springs, inserting their ends into the holes of the coupling and fork;

- fasten the clutch release coupling lubrication hose by screwing its ends into the coupling and clutch housing;

- screw angular oilers into the end of the hose secured to the clutch housing and into the holes for lubrication of the bearing journals of the clutch release shaft;

- set synchronizers 5, 10, gear 12 of the first gear and reverse in the neutral position, apply a gasket to the mating plane of the gearbox housing 18 with the upper cover 13, aligning the holes for the bolts, install the upper cover 13 on the gasket in assembly, aligning the gear shift forks with the grooves of synchronizers 5 and 10 and gear 12 of the first gear and reverse, screw the bolts into the aligned holes and tighten them evenly

- install the gasket of the remote gear shift mechanism on the studs of the upper roofs ki, place the remote gear shift mechanism assembly on the gasket so that it is directed towards the splined end of the clutch release shaft, and the gear shift lever enters the groove of the gear shift rod head, put spring washers on the studs, screw on the nuts and tighten them until they stop;

- insert the speedometer drive gear into the cover 15 of the rear bearing of the driven shaft 14, install the cover of the replaceable gears with the driven cylindrical gear shaft and secure with bolts;

- lubricate the clutch release sleeve and the clutch release drive shaft bushings through oilers with universal refractory grease.

- Before testing on the bench, the assembled gearbox must meet the following requirements:

- the gearbox shafts, when rotating the input shaft by hand, must rotate freely, without jamming, both with the neutral position of the gear shift lever, and and with first gear and reverse gear disengaged;

- all gears should be shifted without much effort. The rod locks should clearly fix the rods in the engaged and disengaged positions. Simultaneous engagement of two gears is not allowed;

- when rotating the clutch release drive shaft by hand, the clutch release coupling must move freely, without jamming, along the guide cover of the drive shaft bearing until the ends of the coupling and the cover touch.

When testing a repaired gearbox on a stand, it is allowed to use regenerated diesel oil DP - 11 as a lubricant, heated to a temperature of 65 ° C, poured into the gearbox and into the remote control mechanism.

Gearboxes are tested in all gears both without load and under load, creating 2 braking torque on the driven shaft.

The operation of the gearbox on the stand in any engaged gear must occur without sharp noises and knocks. The noise level is assessed by ear, comparing with the reference gearbox.

Gear shifting must occur without great effort and jamming. With the gearshift lever in neutral and the drive shaft at maximum speed.

A slight rotation of the driven shaft is allowed, eliminated by a torque of no more than 15 Nm (1.5 kg/cm) applied to the flange.

Oil leakage through the gearbox joints is not allowed. Minor oil leakage through the seals and breather is possible, but without dripping.

The oil temperature in the gearbox sump during testing must not exceed 85°C.