Only the crankcase, the bearing cap of the drive shaft, the intermediate shaft, the reverse gear block, the third gear pinion of the driven shaft, the housing and the base of the oil pump are subject to repair in the gearbox.

The remaining parts of the gearbox are subject to replacement if they are visibly damaged or worn.

The gearbox housing, cast from a special cast iron, is subject to restoration if the holes for the bearings of the drive, driven and intermediate shafts, the holes for the bearing axis of the reverse gear block, the holes for the mounting pins and damage to the threaded holes are worn.

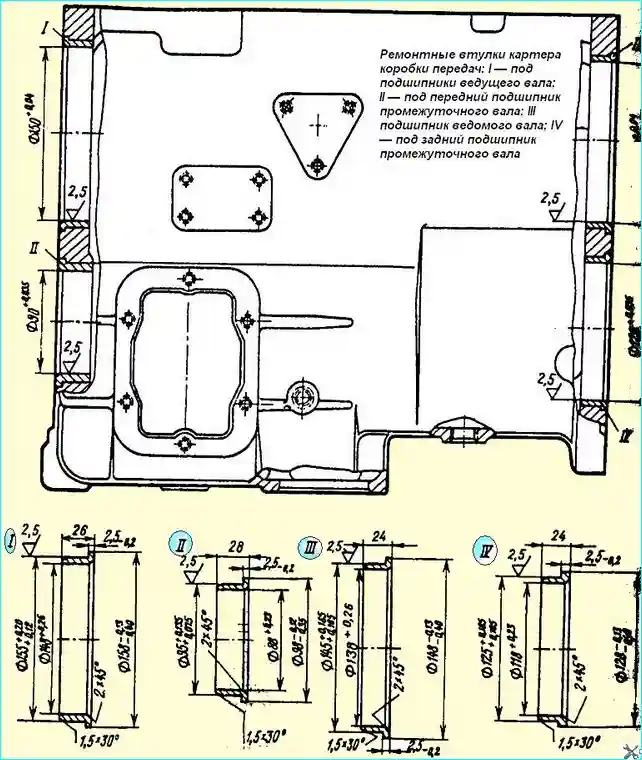

Fig. 1. Gearbox housing repair bushings: I - for the input shaft bearings; II - for the front bearing of the intermediate shaft; III - driven shaft bearing; IV - for the rear bearing of the intermediate shaft

When the holes for the bearings of the drive shaft are worn to a diameter of more than 150.08 mm and the driven shaft to a diameter of more than 140.08 mm, they are restored by installing bushings.

To do this, the hole for the bearing of the drive shaft is bored to Ø 155+0.08 mm and at the same time a recess of Ø158+0.3 mm is bored to a depth of 2.5+0.2 mm under the flange of the repair bushing.

Then reinstall the crankcase and bore the hole for the repair bushing of the bearing of the driven shaft to Ø 145+0.08 mm and at the same time bore the recess of Ø 148+0.3 mm to a depth of 2.5+0.2 mm under the flange of the repair bushing. bushings.

Repair bushings (Fig. 1) are pressed into the bored holes until they stop against the flange, ensuring an interference fit of 0.08-0.15 mm, and the holes in the bushings are bored in a line.

The hole for the drive shaft bearing is bored to Ø 150+0.04 mm and the hole for the driven shaft bearing is bored to Ø 140+0.1 mm.

The holes for the front bearing of the intermediate shaft, worn to a diameter of more than 90.07 mm, and the holes for the rear bearing of the intermediate shaft, worn to a diameter of more than 120.07 mm, are also restored by installing bushings.

The hole for the front bearing bushing is bored to Ø 959.07 mm and at the same time, bore a recess Ø 98+0.03 mm to a depth of 2.5+0.5 mm under the flange of the bushing.

Then bore the hole for the repair bushing of the rear bearing to Ø 125+0.08 mm and simultaneously bore the recess to Ø 128+0.3 mm to a depth of 2.5+0.2 mm under the flange of the bushing.

Press the repair bushings into the holes until they stop against the flange, ensuring an interference fit within 0.08-0.15 mm, and bore the holes in the bushings to the nominal size in line.

Bore the hole for the front bearing to Ø 90+0.035 mm, and for the rear bearing to Ø 120+0.035 mm.

When in case of wear of the holes for the reverse gear block axle to a diameter greater than 26.05 mm for the front end of the axle and to a diameter greater than 32.05 mm for the rear end of the axle, they are restored by reaming to one of the repair sizes given in the table, or restored by installing bushings.

When restoring the holes by installing bushings, the holes are drilled for the front end of the axle to Ø 29.8 mm, and for the rear end of the axle to Ø 35.8 mm.

Then the holes are reamed to diameters of 30+0.045 mm and 36+0.05 mm, respectively. Into the holes

repair bushings are pressed, which have the following main dimensions: for the front end of the axle, outer Ø 30+0.095 mm and length 26 mm, for the rear end of the axle - outer Ø 36 mm and length 30 mm.

After pressing in, the bushings are welded in two diametrically opposite places, drilled and reamed holes in the bushings to the nominal diameter (see table).

The holes for the mounting pins, worn to a size greater than 14.03 mm, are reamed to the repair size 14.2+0.013 mm.

Damaged threaded holes are restored by installing inserts on epoxy glue.

Thus, if the threaded hole M16 cl. is damaged. 2 it is drilled to Ø 17.1+0.2 mm, M20 thread is cut with a tap and the insert is screwed in flush with the plane of the base metal.

The requirements for the relative position of the surfaces of the repaired gearbox housing must be as follows:

- - the non-parallelism of the axes of the surfaces of the holes for the ball bearings of the drive and driven shafts relative to the plane of the connector with the top cover is allowed to be no more than 0.12 mm;

- - the non-parallelism of the axis of the surfaces of the holes for the ball bearings of the drive and driven shafts relative to the axis of the surfaces of the holes for the bearings of the intermediate shaft must not exceed 0.08 mm;

- - the non-parallelism of the axis of the surfaces of the holes for the axis of the bearings of the reverse gear block relative to the axis of the surfaces of the holes for the bearings of the intermediate shaft is allowed to be no more than 0.03 mm over a length of 100 mm;

- - the non-perpendicularity of the crankcase ends from the side of the bearing holes relative to the axis of the surfaces of the bearing holes of the drive and driven shafts must not exceed 0.07 mm over a length of 100 mm;

- - the mutual runout of the surfaces of the holes for the bearing axis of the reverse gear block must not exceed 0.05 mm;

- - the deviation of the axes of the surfaces of the bearing holes of the drive, driven and intermediate shafts from their position in the same plane must not exceed 0.08 mm;

- - the deviation of the axes of the surfaces of the bearing holes of the intermediate shaft and the holes for the bearing axis of the reverse gear blocks is allowed to be no more than 0.03 mm over a length of 100 mm;

- - the distance from the axis of the holes for the axis of the reverse gear block to the axis of the holes for the bearings of the intermediate shaft must be (89.25±0.042) mm and to the axis of the holes for the bearings of the driving and driven shafts — (182.75±0.042) mm.

- - the distance between the axes of the holes for the intermediate shaft bearings and for the bearings of the driving and driven shafts should be (165.75±0.042) mm;

- the distance from the axis of the mounting holes to the axis of the holes for the bearings of the driving and driven shafts should be (136±0.15) mm;

- - the distance between the axes of the mounting holes should be (433±0.05) mm;

- - the distance from the plane of the parting of the gearbox housing with the upper cover to the axis of the holes for the bearings of the driving and driven shafts should be (109.5±0.2) mm.

Bearing cover drive shaft, made of malleable cast iron KCh 35-10, is subject to restoration in case of the following defects: breaks and cracks in the pipe, wear of the hole with the oil drain groove, the hole for the oil seal, the holes for the bolts for fastening to the gearbox housing, the end surface of the flange for the retaining ring of the drive shaft bearing.

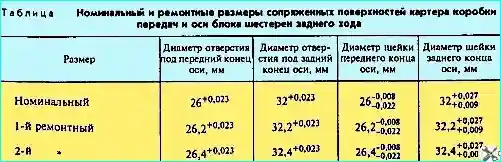

Fig. Repair bushings of the drive shaft bearing cover: 1 - under the clutch release sleeve; 2 - under the oil drain groove; 3 - under the oil seal

In case of breaks and cracks on the cover pipe, cut off the damaged pipe, maintaining a size of 60 mm to the surface of the flange mating with the gearbox housing, bore the hole to 55+0.06 mm through the repair sleeve (Fig. 2) and grind down the chamfer 5 x 45°.

Then press the repair sleeve 1 under the clutch release sleeve into the bored hole, weld it from the outside with a continuous seam, preventing overheating of the base metal, and install it on the faceplate.

Trim the end of the pipe to the length of the entire cover, equal to 170 mm, grind the outer surface to Ø 55.5-0.1 mm and a chamfer of size - 1.5x30°, bore the hole, Ø 44 mm for a length of 90 mm and chamfer measuring 1x45°.

After this, install the cover with the coupling surface in the chuck with extended jaws, trim the end of the pipe flush with the base metal, grind the hole for the oil drain groove to 42+0.34, bore the chamfer in this hole at an angle of 30° to Ø 50 mm and cut a spiral oil drain groove with a special tap with a pitch of 4 mm, a width of 3 mm and a depth of 1.0 mm.

The number of turns should not be less than four. Finally, the neck for the clutch release sleeve up to Ø 55 mm is processed in special mushroom centers on a cylindrical grinding machine.

The hole with an oil scraper groove, worn to a diameter of more than 42.70 mm, is bored to Ø 46+0.05 mm over a length of 30+0.34 mm for a repair sleeve (see Fig. 2).

Then press the sleeve into the bored hole until it stops against the ledge, trim the end of the sleeve flush with the base metal, bore the hole to Ø 42 mm for the oil scraper groove, bore a chamfer in the hole at an angle of 30° to Ø 50 mm and cut an oil scraper groove.

When the hole for the oil seal is worn to a size of more than 64.12 mm, its restore by installing a bushing.

To do this, bore the hole to Ø 68+0.06 mm over a length of 24.5+0.34 mm, press bushing 3 (see Fig. 2) into the bored hole until it stops, aligning the holes in the bushing with the oil channel in the cover, trim the end of the bushing flush with the base metal, bore the hole in the bushing for the oil seal to Ø 64+0.06 mm and bore a chamfer of 1.5x30°.

The hole for the oil seal is bored in the reverse faceplate, based on the surface of the groove for the outer race of the ball bearing.

The holes for the bolts fastening the cover to the gearbox housing, worn to a diameter of more than 11.5 mm, are welded with an electrode ЦЧ-4 Ø 3 mm.

Then clean the welded surface of the flange flush with the base metal, drill six holes 0 11 mm and countersink the holes from the pipe side to Ø 18 mm.

If the end surface of the cover under the bearing retaining ring is worn to a size greater than 3.05 mm, trim the worn end “as clean” to Ø 160 mm, bore a chamfer of 0.3x45°, trim the end of the flange Ø 200-0.047 mm, ensuring a deep the groove for the retaining ring is (2.85 ± 0.1) mm, and the end face of the groove for the outer race of the ball bearing is trimmed to Ø 150 mm, ensuring a size of (7.6 ± 0.1) mm from the end face of the groove to the end face of the flange.

When repairing the drive shaft bearing cover, the following requirements must be met:

- - when centering the cover on the surface for the outer race of the ball bearing with an emphasis on the end face of the flange, the runout of the outer surface of the flange should not be more than 0.04 mm;

- - the runout of the surface of the hole for the oil seal should not exceed 0.08 mm;

- - the runout of the surface of the hole with the oil scraper thread is allowed to be no more than 0.2 mm;

- - the runout of the surface for the clutch release sleeve should not be more than 0.2 mm;

- - mutual non-parallelism of the flange ends and the recess for the bearing is allowed to be no more than 0.05 mm.

The intermediate shaft is made of 15KhGNTA steel and cemented to a layer depth of 0.9-1.2 mm on the teeth with subsequent heat treatment to a tooth surface hardness of HRC 58-64.

The hardness of all ground surfaces must be at least HGC 50.

The intermediate shaft is restored in case of the following defects: broken teeth, chipping of the working surface of the teeth, wear of the teeth along the ends, teeth along the thickness, necks under bearings and necks under shaft gears.

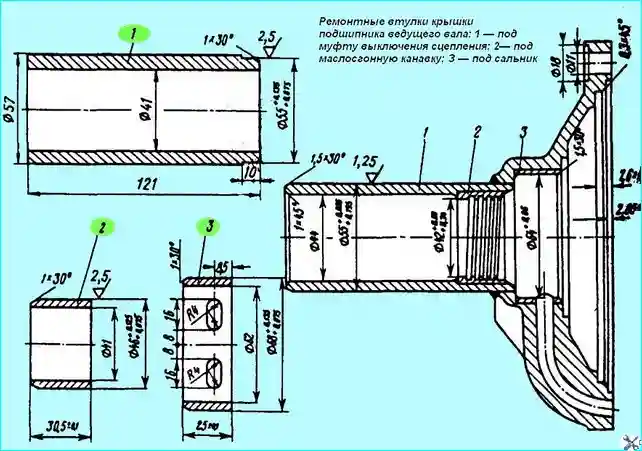

In case of broken teeth, chipping of the working surface of the teeth, wear of the teeth along the ends to a size less than 62.0 mm and when the teeth wear out in thickness to a size of less than 7.65 mm, a repair crown is installed.

To do this, anneal the 59 mm neck and the toothed crown on a high-frequency installation, heating them to a temperature of 780-800 ° C, and place them in a box with dry sand.

Then straighten the shaft until the runout is eliminated in a device on a hydraulic press.

The runout of the ground surfaces relative to the necks under the bearings should not exceed 0.025 mm.

After this, correct the center holes of the shaft on a screw-cutting lathe, install the shaft in the center of the machine, turn the toothed crown to Ø 59 mm, the neck Ø 59 mm to a diameter of 46.5-0.12 mm over a length of 138.7-0.16 mm for grinding and chamfering 5 x 45°.

Then grind the neck under the repair crown to Ø 46 mm over a length of 68-0.2 mm (Fig. 3, a) and the neck under the bushing to Ø 45.9+0.057 mm over a length of 70.7 mm.

Install the shaft on the support of the hydraulic press and press on the toothed crown (Fig. 3, b) until it stops against the end face, ensuring an interference fit within 0.02-0.05 mm.

The toothed crown is heat treated before being pressed onto the shaft and is made of the same steel as the shaft.

Fig. repair of the intermediate shaft by replacing the repair ring gear; (a) - shaft before replacing the ring gear; (b) - shaft assembly; (c) - toothed ring gear; (g) - bushing

Then the toothed (Fig. 3, c) crown is welded to the shaft with a circular weld from both sides (without melting the keyway and tooth cavities) with an electrode of the UONI-13/55 brand Ø 4 mm in a device installed in a bath with water.

After this, the shaft is straightened until the runout is eliminated, the weld is turned from the side of the keyway, deepening it by 0.5 mm from the surface of the neck, the end of the crown is trimmed “as cleanly” and the weld is turned from the opposite side of the crown.

The bushing is pressed onto the shaft until it stops.

In the crown, ensuring an interference fit within 0.02-0.05 mm, the end of the bushing is trimmed flush with the shaft, ensuring size 13З,5-0,15 mm to the end face of the crown and blunting the edges of the bushing with a radius of 0.5 mm.

The worn neck under the front bearing is restored by vibratory arc surfacing, and the necks under the shaft gears are chromium plating.

The reverse gear block is made of 15KhGNTA steel and cemented to a layer depth of 0.9-1.2 mm on the teeth, followed by heat treatment to a tooth surface hardness of HRC 58-64.

The gear block is restored when the teeth of the small crown are broken or the working surface of the teeth of the small crown is chipped, when the small crown is worn along the ends and thickness.

The gear block is rejected when the teeth of the large crown are broken or the working surface of the teeth is chipped, when the teeth of the large crown are worn by thickness to a size less than 6.25 mm and with wear of the hole for roller bearings to a size greater than 52.10 mm.

In case of breakage of teeth of the small rim, wear on the ends to a size less than 25.0 mm and wear by thickness to a size less than 7.60 mm, a toothed rim is installed.

To do this, anneal the defective rim, heating it to a temperature of 780-800 ° C, and place it in a box with dry sand.

Then turn the toothed rim to Ø 72-0.12 mm over a length of 35-0.12 mm, turn the chamfer 5x45 ° and grind the neck to Ø 72 mm.

Press the toothed rim (Fig. 3) onto the machined neck of the gear block flush with the end of the block, ensuring a tension of 0.05-0.08 mm.

The gear block is installed in the fixture, immersed in a bath with a 4% solution of soda ash and The crown is welded with a circular weld on both sides using a UONI-13/55 Ø4 mm electrode.

During the welding process, some deformation of the hole for the roller bearings is possible.

Therefore, the hole is ground to Ø 52 mm at the deformation site on an internal grinding machine, with an E25SM2-S2K PP40x60x20 grinding wheel.

The end face of the gear block from the small crown side is ground to a size of 125-0.15 mm on a cylindrical grinding machine.

The third gear pinion of the driven shaft is made of 15KhGNTA steel and cemented to a tooth depth of 0.9-1.2 mm, followed by heat treatment to a hardness of HRC58-64. Hardness of the tooth core HRC 30—45.

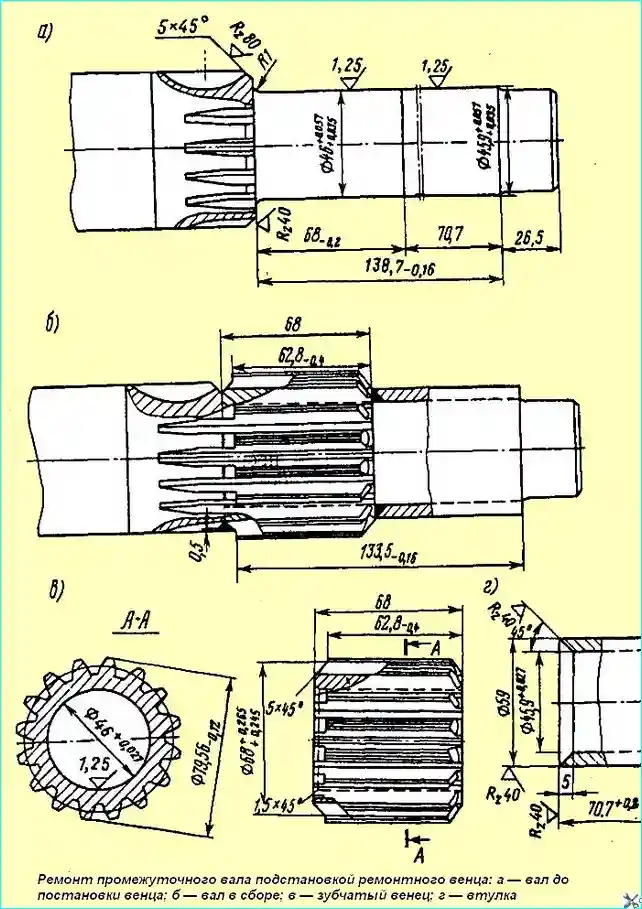

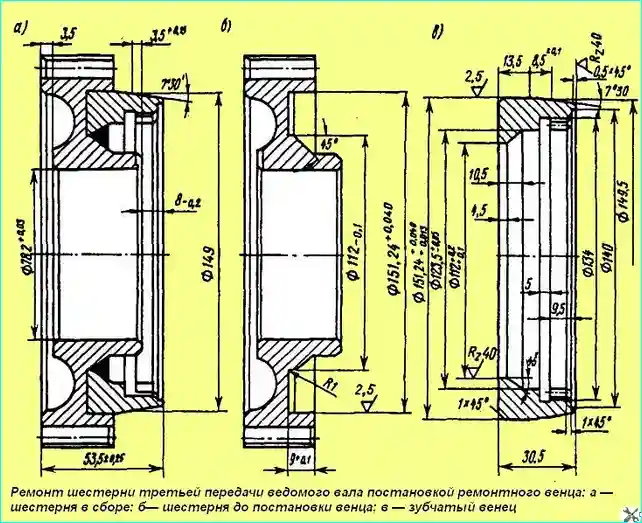

Fig. Repair of the third gear pinion of the driven shaft by replacing the repair rim: (a) - assembled pinion; (b) - pinion before replacing the rim; (g) - toothed rim

The gear is restored with the following defects: broken internal engagement teeth or chipping of the working surface of the teeth, wear of the internal engagement teeth along the ends with a size of less than 8.0 mm and wear of the internal engagement teeth along the thickness, with a play of more than 0.85 mm between the gear teeth and the mating reference part with a size of 138.366+0.152 mm, measured by balls Ø (7.938 ± 0.005) mm.

With these defects, the gear is restored by installing the toothed rim (Fig. 4, a).

To do this, the gear is annealed in an electric furnace, heating to a temperature of 780-800 ° C, and cooled together with the furnace.

Then the damaged toothed rim is cut off the ring gear and the conical part of the gear flush with the end face of the gear, bore the seat for the ring gear (Fig. 4, b) to Ø 112 mm and Ø 151.24+0.040 mm to a depth of 9+0.1 mm and, having provided a fillet with a radius of 1 mm, grind a chamfer on the surface of Ø 112-0.1 mm at an angle of 45° to the surface of the gear hub.

The gear is machined in a faceplate on a screw-cutting lathe.

The ring gear (Fig. 4, c) is pressed into the bored seat of the gear and the runout of the conical surface of the ring gear is checked (which should not exceed 0.06 mm), based on the inner hole of the gear, the ring gear is welded to the gear with a circular solid electrode of the brand UONI-13/55 Ø4 mm and grind the deposited one to a size of 25+0.52 mm from the end of the gear.

Then the gear is hardened by heating it for 50 minutes to a temperature of 825˚-850 ° C and holding at this temperature for 15 minutes.

Then the gear is cooled in SU machine oil, tempered by heating for 70 minutes to a temperature of 170-200 ° C and holding at this temperature for 20 minutes, and cooled in air.

After hardening, the gear is cleaned of scale, the hole in the gear is ground to an increased Ø 78.20+0.03 mm in a special faceplate on an internal grinding machine, based on the pitch circle of the constant-grip teeth.

The conical surface is ground toothed rim, providing Ø 149 mm at a distance of 3.5+0.15 mm from the end of the gear hub on the rim side, and an angle of 7° 30'.

The runout of the conical surface relative to the surface of the hole in the gear should not exceed 0.05 mm.

The conical surface of the toothed rim is checked with a conical gauge for paint. The mating surface with the conical gauge should not be less than 65%.

The toothed rim is made of the same steel as the gear. The rim is cemented before pressing into the gear. The parameters of the crown teeth must correspond to the working drawing of the gear.

The oil pump housing is restored when the gear seats are worn out by diameter, the driven gear axis, the hole in the bushing for the oil pump shaft.

When the gear seats are worn out by a diameter of more than 43.10 mm and the end surface of the gear seats is worn out to a size of more than 16.0 mm, boring is carried out to an increased diameter with subsequent installation during assembly of gears with an increased outer diameter.

For this, the bosses of the holes for the fastening bolts are faced to a size that ensures the same height of all the bosses. This size should not be less than 22 mm.

Then install the pump body with the ends of the machined bosses on the device, machine the end of the seat for the gears “as cleanly as possible”, face the mating surface of the body with the pump base to the depth of the seat (16.5 ± 0.03) mm, and bore the seats for the driven and driving gears to Ø 45.5 + 0.05 mm.

The non-flatness of the mating surface of the body with the pump base should be no more than 0.02 mm, and the non-parallelism of the end surface of the seats for the gears should be no more than 0.05 mm over a length of 100 mm.

The surfaces under the axis of the driven gear and the driven gear, the surfaces of the sleeve under the shaft and the driving gear should be pairwise concentric, the permissible runout is no more than 0.03 mm.

The housing is rejected if the height of the bosses for the oil pump mounting bolts is less than 20.5 mm.

The worn axle is driven gears with a diameter of less than 13.95 mm are replaced with new ones. To do this, drill a Ø 6 mm hole in the pump housing on the opposite side of the axle until the drill stops against the axle.

Press out the defective axle from the housing, press in a new axle and weld the hole in the housing with a Ø 3 mm copper-steel electrode.

After pressing in, the driven gear axle should be recessed from the mating surface of the housing with the pump base by (1±0.5) mm.

If the hole in the bushing for the shaft of the drive gear of the oil pump wears out to a diameter of more than 14.06 mm, replace the bushing.

To press out the bushing from the housing, secure an M16 tap in a bench vice and screw the tap into the bushing by rotating the oil pump housing.

Then lightly tap the housing with a hammer to press the bushing out of the housing. The new bushing is pressed into the housing with a recess of 0.5 mm from the end surface of the seat for the drive gear.

The hole in the bushing is reamed to Ø 14+0.040

The difference in wall thickness of the bushing is allowed to be no more than 0.3 mm.

The distance between the axes of the holes for the axles and the shaft of the gears should be 34.42+0.04 mm and the non-perpendicularity of the axes of the holes to the mating surface of the housing with the base of the pump should be no more than 0.05 mm over a length of 100 mm.

The base of the oil pump is restored if there are scratches and burrs on the end surface for the gears and if the hole in the bushing for the shaft of the oil pump is worn.

If there are scratches and burrs, the end surface for the gears is ground "as clean" on a surface grinding machine, with a KCh40MZ-SM1K PP250x25 grinding wheel

The machined surface should be 0.5 mm higher than the rest of the base.

If the height is lower, the base is rejected.

The gear surface is ground in a special device, and the surface adjacent to the gearbox housing is taken as the base surface, since these surfaces must have a non-parallelism of more than 0.05 mm over a length of 100 mm, and the total machined surface must be flat with an accuracy of no more than 0.02 mm.

When the hole in the bushing for the oil pump shaft wears out to a size greater than 14.06 mm, the bushing is pressed out and a new bushing is pressed in, sinking it into the base 0.5 mm from the mating surface with the pump body.

Then the hole in the bushing bore and ream to Ø 14+0.040 in a special faceplate on a lathe, based on the mounting surface of the mating with the gearbox housing Ø 90 mm.

The axes of these surfaces must be concentric, should not exceed 0.08 mm. The perpendicularity of the axis of the sleeve surface to the end surface under the gears should be no more than 0.05 mm over a length of 100 mm