The use of contaminated oils is not allowed.

It is not allowed to engage the gear in the main box until the selected range of the demultiplier turns on, that is, until the control lamp lights up when the slow range is turned on or until it goes out when the fast range is turned on

Demultiplier switching time 0.5—1.0 sec.

When the car is moving, it is strictly forbidden to engage the first gear in the main gearbox with the fast range of the demultiplier switched on.

Engage first gear and reverse gear only after the car has come to a complete stop and the slow range is on in the demultiplier.

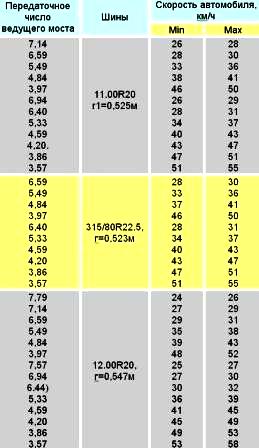

It is not allowed to turn on the slow range of the demultiplier when the vehicle speed is higher than the minimum speed indicated in table 1.

It is not allowed to shift gears while the vehicle is moving with the power take-off engaged.

It is not allowed to increase the engine speed when the vehicle is braked by the engine, in excess of the maximum idle speed.

The maximum oil temperature in the gearbox is 120˚C. Short-term operation is allowed (for no more than 2 hours) at oil temperatures up to 145˚С.

Preparing the gearbox for work

Before operation, it is necessary to check the connection of the gearbox control systems to the corresponding vehicle systems;

- —pneumatic system for controlling the demultiplier to the pneumatic valve of the gearshift mechanism located in the gearshift lever and the pressure reducing valve to the vehicle pneumatic system;

- - power supply of an automatic electronic-pneumatic type locking system (ASBP) to the vehicle's electrical circuit;

- - power supply of the control lamp for switching on the slow gear in the demultiplier and the lamp for switching on the reverse gear to the electrical system of the car;

- - shift roller lever to the gearbox control drive.

Check the oil level in the gearbox, to do this, unscrew the plug with a level indicator from the filler hole located on the right side of the gearbox housing, and then insert the plug with the indicator into the hole until it stops into the thread.

The oil level should be at the top mark on the pointer. After checking the oil level, screw the plug into the hole.

Check the operation of the ASBP, for which first make sure that when the slow gear is turned on in the demultiplier, the control lamp is on, and when switching to a fast gear, it goes out.

Shift gears in the demultiplier with the range switch located on the gear lever handle, at an air pressure in the vehicle’s pneumatic system of at least 450-490 kPa (4.5-4.9 kgf / cm²).

Accelerate the car to a speed of 5-10 km / h above the maximum speed indicated in table 1.

Determine the maximum speed according to the table for each vehicle, depending on the rear axle gear ratio and the tire model installed on the vehicle.

Depress the clutch, disengage a gear in the main gearbox, engage a slow gear in the demultiplier and watch the warning light and vehicle speed.

If the switching occurs immediately (the control lamp lights up) after turning on the slow gear in the demultiplier at a speed higher than the maximum speed indicated in table 1, the ASBP is faulty.

In this case, without releasing the clutch pedal, reduce the speed by 5 km/h below the minimum speed indicated in Table 1, and then switch.

If the inclusion of a slow gear in the demultiplier occurs at a vehicle speed below the minimum specified in table 1. - ASBP is working properly.

Check the operation of the first gear and reverse gear air lock in the main gearbox in the following sequence;

- —set the gear lever to neutral position;

- - turn on a slow gear in the demultiplier and make sure that the force on the head of the gear lever when moving it towards the first gear and reverse gear is 5-10 kg;

- - turn on a fast gear in the demultiplier and check the force on the head of the gear lever when moving it towards the first gear and reverse gear; the force should be 4-5 times greater compared to the inclusion in a slow gear in the demultiplier.

Maintenance

Maintenance work is mandatory and must be carried out strictly on time.

Maintenance of the gearbox according to the frequency and work performed is divided into the following types:

- - daily maintenance (EO);

- - technical obstinning after a car break-in (1000 km);

- — first maintenance (TO-1);

- — second maintenance (TO-2).

The frequency of maintenance of the gearbox (TO-1 and TO-2) corresponds to the frequency of maintenance of the vehicle on which it is installed.

During maintenance, it is necessary to ensure conditions that exclude the ingress of dust and dirt into the gearbox components.

Daily Maintenance

Check by visual inspection if there are any oil leaks from the gearbox. Check the tightness of the pneumatic control system of the demultiplier.

Air leaks are identified by ear. Alternately moving the range switch to the upper and lower positions, listen to the air ducts with the lever in the main box in the neutral position and with any gear engaged.

If oil or air leaks are detected, find the cause and fix the problem.

Maintenance after running in the car

After running the car, drain the oil from the gearbox housing, clean the drain plug magnet from metal particles, and clean the cover installed from below on the lower crankcase from wear products.

Drain the oil from the box immediately after working while hot.

After draining the oil, flush the box crankcase with liquid industrial oil, for example, I-12A or I-20A according to GOST 20799-88.

Do not flush the gearbox with diesel fuel or kerosene. Fill with fresh oil up to the upper mark on the level indicator.

First maintenance (TO-1)

Check the oil level and top up if necessary.

Change the oil in the gearbox with maintenance operations after the vehicle has been broken in.

Clean and lubricate with Litol-24 grease the spool, piston, inner surfaces of the air distributor cylinders, piston cuffs and the inner surfaces of the demultiplier switching cylinder.

Check the operation of the ASBP.

Check the air pressure at the outlet of the pressure reducing valve, which should be within 450-500 kPa (4.5-5kgf/cm²).

Check the tightness of the range control pneumatic system, eliminate the detected air leaks by tightening the bolts or replacing the sealing washers.

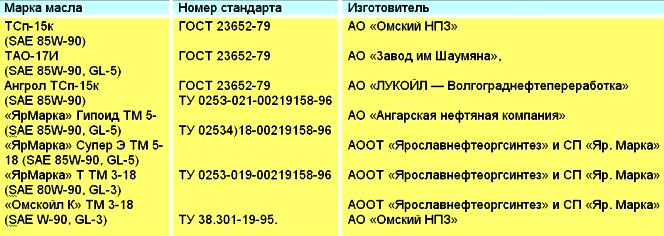

Gear oils approved for use in the gearbox and recommended viscosity grades of gear oils depending on the ambient temperature, °C, are shown in Table 2.

- 1. When the ambient temperature is below minus 20˚C, it is allowed to use a mixture of gear oil approved for use (85%) with diesel fuel grade "A" or "Z" (15%).

- 2. Oil MT-16P GOST 6360-83 is allowed for use in a gearbox with a halved replacement period.

- 3. It is allowed to use imported gear oils with an API performance level of at least GL-4, viscosity grade according to table 2.

Possible gearbox failures

Reasons

Remedy

- Difficulty engaging gears in the main gearbox. The inclusion of the first gear and reverse occurs with a rattle

- Incomplete clutch disengagement (clutch leads)

Adjust clutch pedal freeplay or replace damaged parts

- Difficulty shifting into 2nd, 3rd, 4th and 5th gears. Turning on occurs with a rattle

- Wear of conical synchronizer rings

Replace Synchronizer

- Gears are not included in the main box

- Wear of the gear rims of the synchronizer carriage, gear couplings mounted on the gears of the 2nd, 3rd, 4th and 5th gears, the gear clutch for engaging the first gear and reverse, or the gear rims of the gears of the first gear and reverse

Replace defective parts

- Wear of parts or misalignment of the remote gearshift drive

Replace defective parts; adjust remote shifter

- Engaging gears in the demultiplier occurs with a bang and a rattle

- Increased pressure in the pneumatic control system of the demultiplier

Adjust pressure reducing valve

- - Wear of the cone rings in the synchronizer

- - Wear of the blocking chamfers of the fingers and synchronizer carriage

Replace Synchronizer

- Non-disengagement or delayed engagement of gears in the demultiplier with the neutral position of the main gearbox shift lever.

- The indicator lamp does not go out for a long time when the fast range is turned on and does not light up for a long time when the slow range is turned on.

- Air exits through air distributor saloon

- wearintake valve rubber

Replace valve

- Valve stem O-ring wear

Replace O-ring

- Uneven fit of the inlet valve to the shoulder of the body

Replace O-ring

- Inlet valve sticking in the depressed position

Replace defective parts

- O-ring hardening inlet valve body ring

Rinse, blow out and lubricate the valve stems and cap bore. Polish the stem if necessary

- Wear or hardening of the O-rings of the power cylinder piston rod

Replace O-rings

- Air exits through the gearbox breather when the slow gear is engaged in the demultiplier

Replace O-ring

- Wear or hardening of the O-ring of the air distributor piston

Replace O-rings

- Wear or hardening of the O-rings of the air distributor spool

Replace cuff

- Low pressure in the pneumatic system of the gearbox

Replace cuff

- Wear or hardening of the cuff of the piston of the power cylinder

Replace Aperture

- Air distributor inlet valve diaphragm rupture

Replace Aperture

- Air comes out through the gearbox breather.

Clean or replace breather

- Rupture of the diaphragm of the locking device of the first gear and reverse

Replace defective parts

- Air exits through the gearbox breather when the fast gear is engaged in the demultiplier

Clean or replace breather

- Self-deactivation of gears while driving

- Incomplete gear engagement due to wear of the fork crackers, due to misalignment of the remote control drive

Tighten fasteners, replace worn parts, adjust control drive.

- Wear of gear couplings of gears and synchronizer carriages due to incomplete engagement

Replace worn parts

- Increased noise during gearbox operation

- Loosening the bolts securing the clutch housing to the flywheel housing

Tighten bolts

- Gear teeth wear

Replace gears

- Wear of shaft or gear bearings

Replace bearings

- Not enough oil in the gearbox

Add oil up to the upper mark on the oil level indicator

- Gearbox oil leak

- Wear or loss of elastic cuffs

Replace cuffs

- Increased crankcase pressure

Rinse breather

- Violation of tightness on sealing surfaces

Tighten fasteners

- Enable slow range at vehicle speeds higher than recommended

- Opening the contacts of the electrical circuit

Restore contact

- Broken wires of the ASBP system

Replace Wire

- Faulty ASBP blocking relay

Replace relay 6312.3747

- Faulty speed sensor

Replace speed sensor 1101.3843

- Faulty blocking valve

Replace defective parts