During operation, there are cases when a liner crack occurs

When a crack forms, bubbles appear in the expansion tank

We determine in which cylinder the liner crack has formed as follows:

Drain some of the coolant.

Remove the air intake manifold.

Fill in coolant according to the level of the holes in the heads.

Start the diesel engine and see from which hole in the heads bubbles begin to emerge.

Where bubbles appear, there will be a microcrack.

You can quickly remove the sleeve as follows:

Remove the cylinder head.

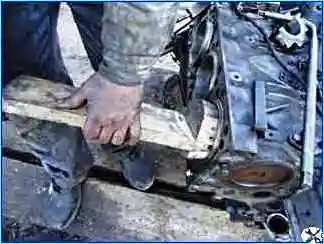

Using an ax and a hacksaw we make a block of smaller diameter.

It should fit freely into the cylinder liner.

The height should be approximately 100 mm. We split it in half.

We make a wedge from a suitable board.

Rotate the crankshaft so that the piston goes down.

We insert our device into the sleeve.

We hammer in the wedge. (Operations shown with engine removed)

Rotating the crankshaft, the piston, resting against our device, pushes out the sleeve.

Install a new sleeve and assemble in reverse order.

You can change the liner on an installed engine without removing the pan.

To do this, you need to make a pass on the new sleeve on a lathe so as not to break the rings.