The engine cooling system is liquid, closed type, with forced circulation of coolant

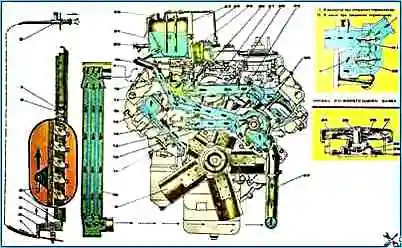

The main elements of the system are the water pump, radiator, thermostats, fan, fan drive fluid coupling, fluid coupling switch, expansion tank, bypass pipes, louvers.

Engine cooling system diagram: 1 - Protective tube, 2 - Brake drive lever, 3 - Brake drive mounting bracket, 4 - Radiator brake tension frame, 5 - Brake linkage, 6 - Radiator brake plates, 7 - Louver drive rod, 8 - Radiator blind control rod, 9 - Fan impeller, 10 - Radiator, 11 - Cooling system drain cock; 12 - Right half-block inlet pipe; 13 - Inlet pipe branch; 14 - Fan drive fluid coupling switch; 15 - Cylinder head; 16 - Drain cock handle; 17 - Thermostat housing; 18. Coolant drain pipe from the expansion tank to the water pump; 19 - Coolant drain pipe to the heater; 20 - Coolant level control valve; 21 - Expansion tank; 22 - Air-steam lock; 23 - Bypass pipe from the radiator to the expansion tank; 24 - Connecting pipe from the compressor to the expansion tank; 25. Compressor; 26 - Right water collection pipe; 27 - Connecting water pipe; 28 - Left water collection pipe; 29 - Bypass pipe from thermostats; 30 - Water pump; 31, 32 - Thermostat valves; 33 - Elbow of the outlet pipe; 34 - Plug housing; 35 - Valve stand; 36 - Spring; 37 - Cover spring; 38 - Exhaust valve (58-80 kPa)(0.58-0.8 kgf/cm2); 39 - Exhaust valve; 40 - Gasket

During engine operation, the circulation of coolant in the system is created by a centrifugal pump.

The liquid from the pump is pumped into the water cavity of the left bank of cylinders, and through the pipe - into the water cavity of the right bank of cylinders.

Washing the outer surfaces of the cylinder liners, the coolant enters the water cavities of the cylinder heads through the holes in the upper mating surfaces of the cylinder block.

From the cylinder heads, hot liquid enters the thermostat box through the water collection pipes, from which, depending on the temperature, it is directed to the radiator or to the inlet of the water pump.

The temperature of the coolant in the system is maintained within 80-98 ° C.

The thermal mode of the engine is automatically ensured by thermostats and a fan drive fluid coupling switch, which change the direction of the liquid flow and the fan operating mode depending on coolant temperature in the engine cooling system.

To speed up engine warm-up and maintain the engine temperature in the cold season, blinds are installed in front of the radiator.

Thermostats with solid filler and direct valve travel, designed for automatic regulation of the engine thermal mode, are located in a box fixed to the front end of the right row of the cylinder block.

When the engine is cold, the liquid inlet to the radiator is blocked by a valve, and the inlet to the bypass pipe to the water pump is open by a valve.

The coolant circulates, bypassing the radiator, which speeds up engine warm-up.

When the coolant temperature reaches 80 °C, the active mass - ceresin, contained in the cylinder, melts, increasing in volume. At the same time, the cylinder begins to move to the right, opening the valve and closing the valve.

The coolant begins to circulate through the radiator.

At a temperature range of 80-93 ° C, the coolant continues to flow through the bypass pipe to the pump inlet and through the radiator, the valves are partially open.

At a temperature of 93 ° C, the valve opens completely, and all the liquid circulates through the radiator.

When the coolant temperature drops to 80 ° C and below, the volume of ceresin decreases, and the valves, under the action of the thermostat springs, take their original position.

The fan drive fluid coupling transmits torque from the crankshaft to the fan.

The front cover of the block and the bearing housing are connected with screws and form a cavity in which the fluid coupling is installed.

The radiator louvers are designed to regulate the flow of air pumped through radiator grille.

They are made in the form of a set of horizontal plates made of galvanized iron, united by a common frame and equipped with a hinge device that ensures their simultaneous rotation around the axes. The blinds are attached to the radiator frame in front of the cooling grille.

The fan is axial type, heel blade, mounted on the driven shaft of the fluid coupling.

The fan rotates in a diffuser mounted on the radiator frame, which reduces the suction of air from the sides by the blades and thereby helps to increase the air flow sucked by the fan through the radiator.

The expansion tank is mounted on the engine on the right side in the direction of the vehicle and is connected to the thermostat box, the upper radiator tank and the compressor.

The expansion tank is used to compensate for changes in the volume of the coolant when it expands from heating, and also allows you to control the degree of filling of the cooling system and helps remove air and steam from it.

A steam-air plug with an inlet (air) and outlet (steam) valves is installed in the neck of the expansion tank.

The outlet valve, loaded with a spring, maintains excess pressure in the cooling system up to 56.9-78.5 kPa (0.58-0.80 kgf/cm 2), the intake valve, loaded with a weaker spring, prevents the creation of a vacuum in the system when the engine cools down.

The intake valve opens and connects the cooling system to the atmosphere at a vacuum of 0.98-12.7 kPa (0.01-0.13 kgf/cm 2).

The coolant is poured into the engine through the neck of the expansion tank.

The liquid level in the expansion tank is controlled by the level control valve, which should be above the control level valve, while the upper level of the liquid in the tank should be ½-2/3 of the tank height.

The coolant temperature in the system is monitored by the indicator on the instrument panel.

When the temperature in the cooling system rises to 98 °C in The coolant overheating warning light comes on in the indicator.