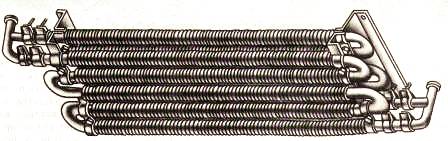

In order to prevent oil dilution, an oil cooler is included in the lubrication system (Fig. 1)

It is installed in front of the water cooler of the cooling system, which provides it with intensive airflow from the oncoming air flow when the car is moving.

The oil cooler must be constantly on, and it should only be turned off when starting a cold engine at an outside temperature below 0 °C.

After warming up the engine, the valve must be opened, otherwise the temperature of the oil in the crankcase will rise, it will become very liquid and the pressure in the lubrication system will drop.

The oil cooler shut-off valve is located under the centrifuge body.

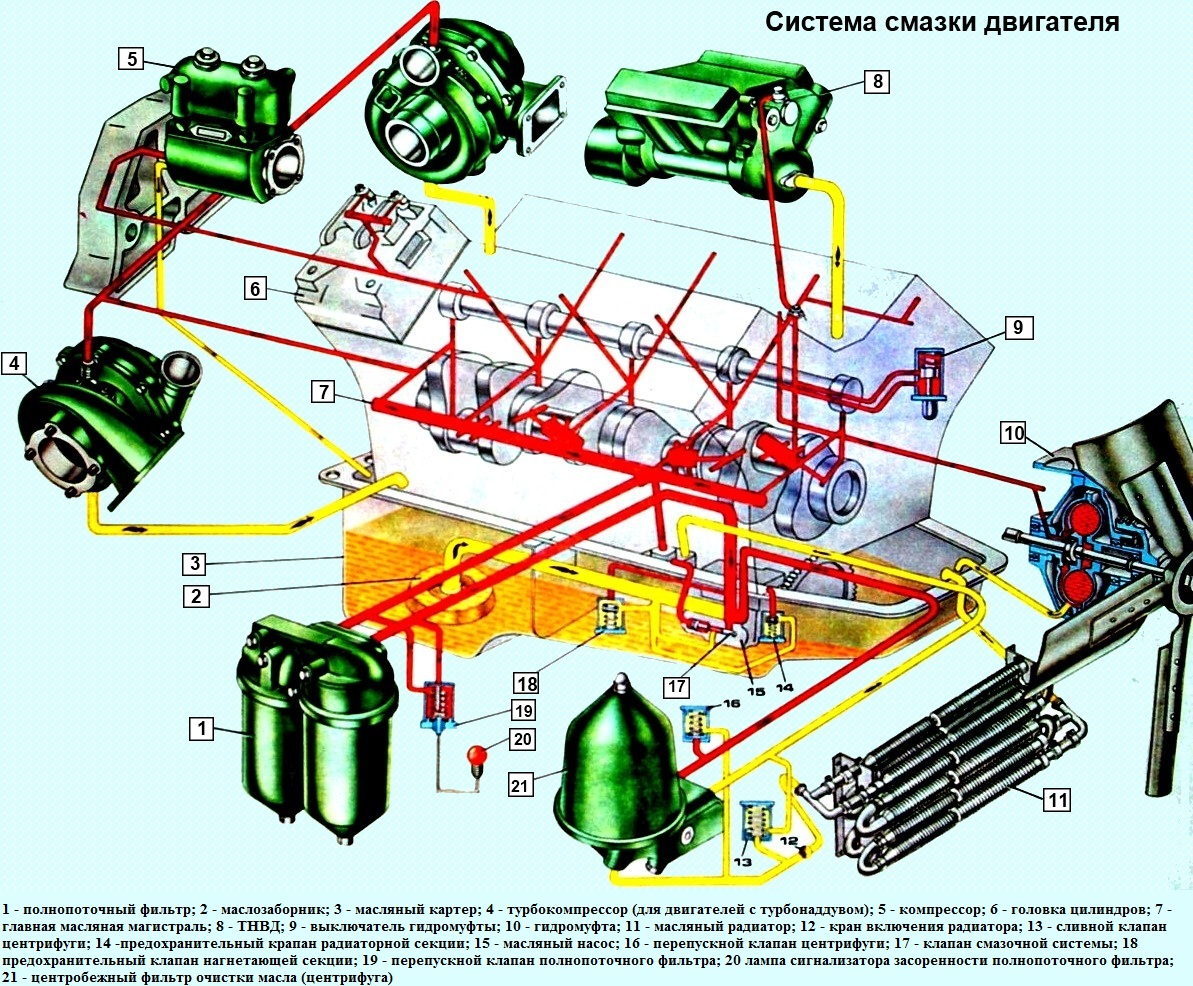

Scheme of the lubrication system is shown in fig. 2.

From the crankcase 3 through the oil receiver 2, oil enters the discharge and radiator sections of the oil pump 15;

- - from the injection section, through the channel in the right wall of the block, it is fed into the oil filter 1, where it is cleaned by two filter elements;

- - then it enters the main line 7, from where it goes through the channels in the block and cylinder heads to the crankshaft main bearings, rocker bushings and upper tips of the pusher rods.

Oil is supplied to the connecting rod bearings of the crankshaft through holes inside the shaft from the nearest main journal.

The oil removed from the cylinder walls by the oil scraper ring is discharged into the piston and lubricates the piston pin bearings in the bosses and the connecting rod bearing.

Through the channels in the rear wall of the cylinder block and the flywheel housing, oil under pressure enters the bearings: compressor 5, through the channels in the front wall of the block - to the bearings of the high-pressure fuel pump 8.

Oil is taken from the main line to be supplied to the switch 9 of the hydraulic coupling 10, which is installed on the front end of the unit and controls the operation of the fan drive hydraulic coupling.

From the radiator section of the oil pump, oil enters the centrifugal filter 21, then into the radiator and then drains into the crankcase.

When the valve 12 is closed, the oil from the centrifugal filter is drained through the drain valve 13, bypassing the radiator, into the crankcase.

The rest of the engine parts and assemblies are lubricated by splashing and oil mist.

Oil cooler maintenance

When servicing an oil cooler, the main defects of which are cavity contamination and oil leakage, clean it by blowing and flushing with hot 10% caustic soda solution, hot water, then kerosene in the opposite direction to air and oil flows.

For flushing with caustic soda solution, use equipment that circulates the liquid.

Check the tightness by filling the radiator with oil under pressure not exceeding 196 kPa (2 kgf/cm2). If a leak is found, replace the radiator.