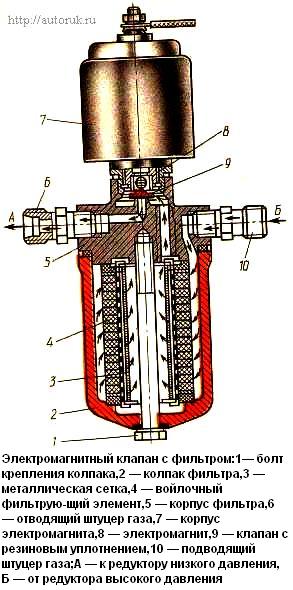

The solenoid valve is used to pass gas to the low pressure reducer when the engine is switched to gas-diesel mode

When the engine is running in diesel mode, valve 9 is closed under the pressure of the electromagnet spring, it is also affected by the pressure of the gas supplied through the fitting 10 from the high pressure reducer.

The gas filter consists of a housing 5, a filter element equipped with a mesh 3 and a pack of felt rings 4.

The housing has two threaded holes for screwing in a fitting for supply 10 and output 6 of gas.

The cap 2 of the gas filter, when mounted on the housing 5, is sealed with a rubber ring and a copper gasket installed on the head of the coupling bolt 1.

The sealing of the solenoid valve connection with the housing 7 is provided by a gasket.

A sealing gasket is installed between the felt rings 4 and the cap 2.

The gas enters through the nozzle channel 10, passes through the felt rings 4, the metal mesh 3 and is supplied to the valve 9 through the channel in the housing 5.

When the engine is switched to gas-diesel mode, power is supplied to the solenoid valve.

The current passes through the winding of the electromagnet and under the influence of the electromagnetic field, the core, overcoming the force of the spring, rises and opens the valve 9.

The filtered gas goes to the low pressure reducer.

The need for preventive cleaning of the gas filter is determined by the gas pressure in the first stage of a two-stage low pressure reducer.

A sharp drop in pressure in the first stage during the transition from idle to load operation indicates a clogged filter.