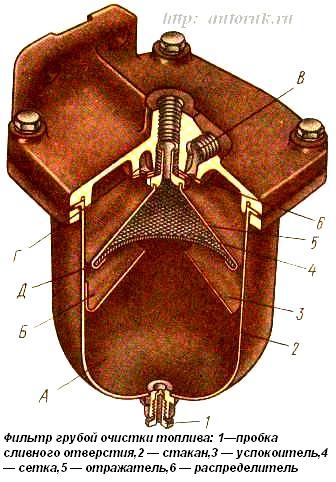

The filter is installed on the left side of the car on the frame and is designed to remove mechanical impurities and water from the fuel (Fig. 1)

Through channel B of the filter, the fuel enters the annular cavity G, from where it flows in thin streams through the holes (8 pcs.) in the distributor 6 onto the reflector 5.

Spreading over the surface of the cone reflector, the fuel loses speed and flows into the annular gap D between the reflector and the glass.

When moving through this gap, the speed of the fuel increases sharply, and when it leaves it in cavity B, its movement slows down again.

From cavity B, the fuel, abruptly changing direction, is sucked in by the booster pump through the grid 4, while mechanical impurities and water drops, under the action of inertia forces, fall into cavity A under the damper 3.

The damper separates cavity A from cavity B, where the fuel circulates, and prevents it from mixing with the sludge even with shaking and vibration.

From the upper part, through the filter mesh and through the outlet fitting and fuel lines, fuel is supplied to the fuel priming pump

Coarse filter maintenance

Unscrew plug 3 on the filter cover by 3-4 turns

Unscrew the drain plug 9 and drain the fuel from the filter cap into a previously prepared container

Use a wrench to unscrew the four bolts 1 fastening the cap 8 of the filter to the cover

Remove the filter cap and remove the old filter element 7

We wash the inner surfaces of the cap with clean gasoline or diesel fuel

Put the new element 7 and the gasket 6 into the groove of the cover

We install the cap and, after making sure that the gasket is in the correct (without displacement), tighten the bolts 3 for fastening the housing on the cover

If access to the filter is difficult, in order to avoid cases of gasket displacement, it is allowed to lubricate the gasket on the cover side before installation at several points with grease

Unscrew plug 3 and fill the filter with clean fuel, then carefully tighten the plug

We start the engine and check the tightness of the filter; tighten bolts 1, eliminate air leakage

Drain filter sediment

To drain the sludge from the coarse fuel filter, unscrew the drain plug by 3-4 turns and drain 0.1 liters of fuel into a set dish

After draining the sludge, close the plug and start the engine for 3-4 minutes to remove air pockets

Draining sludge is especially important in winter to remove condensate