engines

There are many internal combustion engines powered by gasoline, diesel, propane, or natural gas; hybrid vehicles, plug-in hybrids, hydrogen-powered fuel cell vehicles, and all-electric vehicles. Fuel-powered vehicles have an advantage due to their limited range and high battery costs. Some options require a network of refueling or charging stations.

- G4KE Engine Compression Check

- G6EA engine valve clearance adjustment

- Gas distribution mechanism of diesel KAMAZ 740.30-260

- Head cover gasket ZMZ-406

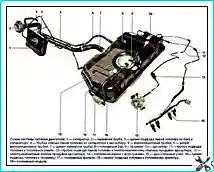

- High-voltage wires and candles ZMZ-406

- How to adjust the engine valve VAZ-21114

- How to adjust the fuel injection of a YaMZ-238 diesel engine

- How to adjust the valve clearances of the 11183 engine

- How to assemble a connecting rod and piston group ZMZ-406

- How to assemble the ZMZ-406 engine