In the fuel injection system of the engine, the pressure is 30 MPa (3 kgf / cm 2)

Therefore, it is forbidden to loosen the fuel line connections while the engine is running or immediately after it has stopped.

To carry out work on the repair of the power supply system on a just stopped engine, it is necessary to first reduce the pressure in the power supply system.

2-3 hours after the engine stops, the pressure in the system drops to almost zero.

A fundamental feature of the ZMZ-4062 engine power system is the absence of a carburetor in it, which combines the functions of mixture formation and dosing of the air-fuel mixture into the engine cylinders.

In the distributed injection system installed on this engine, these functions are separated - the nozzles carry out metered fuel injection into the intake pipe, and the air required at each moment of engine operation is supplied by a system consisting of a throttle and an idle speed controller.

The fuel injection system and the ignition system are controlled by an electronic engine control unit, which continuously monitors the engine load, the vehicle speed, the thermal state of the engine and the environment, and the optimal combustion process in the engine cylinders using appropriate sensors.

This control method makes it possible to ensure the optimal composition of the combustible mixture at each particular moment of engine operation, which allows you to get maximum power with the lowest possible fuel consumption and low exhaust gas toxicity.

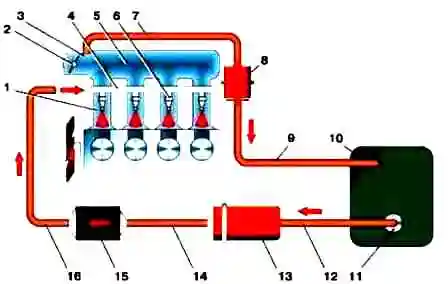

Scheme of the fuel injection system is shown in the figure.

Scheme of the power supply system of the engine ZMZ-4062, ZMZ-40522, ZMZ-40524: 1 - inlet pipe; 2 - air throttle; 3 - throttle; 4 - engine fuel line; 5 - receiver; 6 - nozzle; 7 - vacuum hose; 8 - pressure reducing valve; 9 - fuel drain hose; 10 - fuel tank; 11 - fuel tank receiver; 12 - low pressure fuel line; 13 - fuel pump; 14,16 - high pressure fuel line; 15 - fuel fine filter

Fuel tank 10 welded stamped, secured with two steel clamps through gaskets under the floor of the luggage compartment.

At the top of the fuel tank there is a fuel intake and a fuel level sensor.

Next to the fuel tank under the floor of the body is an electric fuel pump connected by a fuel line to the fuel tank.

To reduce vibration, the pump bracket is attached to the floor through rubber pads.

From the pump, fuel is supplied to the fuel filter installed in the engine compartment, and from there it enters the engine fuel line attached to the engine intake pipe.

From the fuel line of the engine, fuel is injected by injectors into the intake pipe.

Excess fuel is drained to the fuel tank through a pressure reducing valve installed at the rear end of the engine fuel line.

In addition to the element power supply system shown in the diagram, it includes an air filter installed in the engine compartment, connected by a rubber hose to a mass air flow sensor, which in turn is connected to a throttle installed on the air receiver, as well as an idle speed regulator, also installed on the air receiver.

The nozzle is an electromechanical valve in which the check valve needle is pressed against the seat by a spring.

When an electrical impulse is applied from the control unit to the electromagnet winding, the needle rises and opens the atomizer hole through which fuel is supplied to the engine intake pipe.

The amount of fuel injected by the injector depends on the duration of the electric pulse.

Reducing valve is a container divided by a diaphragm, on which a valve is fixed, which closes the fuel drain hole under the action of a spring.

The pressure reducing valve maintains a constant pressure in the supply system of about 0.3 MPa.

The upper part of the pressure reducing valve is connected to the receiver by a vacuum hose.

When the pressure drop in the receiver is not higher than 0.3 MPa, the valve is closed and the pressure in the supply system rises.

When the fuel pressure reaches more than 0.3 MPa, the membrane flexes, opening the hole, and excess fuel drains into the fuel tank.

As soon as the fuel pressure drops to 0.3 MPa, the membrane returns to its original position and closes the fuel drain hole.

The mass air flow sensor is used to determine the amount of air entering the engine cylinders.

The signals from the sensor are sent to the engine control unit and are one of the parameters that determine the duration of the injection then fuel injectors - the amount of fuel depends on the amount of air at any given moment.

The main element of the sensor is a platinum filament heated up to 150 °C during operation.

As engine intake air passes through the sensor housing, the filament cools down, and the sensor electronics constantly strive to maintain the filament temperature at 150 °C.

Electrical power spent on maintaining the temperature of the thread is a parameter by which the engine control unit determines the duration of the electrical pulse applied to the nozzles.

The degree of cooling of the platinum filament depends not only on the amount, but also on the temperature of the passing air, determined by a thermal compensation resistor, which accordingly corrects the signal supplied by the sensor to the control unit.

To provide the ability to adjust the amount of carbon monoxide in the exhaust gases at idle, the electronic module has a variable resistor, with a screw of which you can manually change the value of the signal supplied by the sensor to the electronic control unit, thereby changing the duration of the pulse supplied to the injectors, and hence the amount of injected fuel.

In order to clean the platinum filament from contamination, the electronic module periodically applies an increased voltage to it, causing it to heat up to 1000 °C. In this case, all deposits are burned.

If the sensor fails, the engine control unit turns on a backup program that ensures engine operation with slightly different, but acceptable power and consumption characteristics. At the same time, the control lamp in the instrument cluster lights up.

The idle speed controller serves to maintain the set idle speed of the engine unchanged when it is started, warmed up and load changes caused by the activation of auxiliary equipment.

The regulator is a spool valve with electromagnetic control and serves to supply additional air to the intake pipe, bypassing the throttle.

If the idle speed controller fails or there is no contact in the plug block, the stability of the idle speed is disturbed (the speed “floats”).

The indicator lamp in the instrument cluster comes on.

If the idle speed is unstable and the control lamp does not light up, it is necessary to check the tightness of the connecting hoses.

The throttle position sensor, which is a dual variable semiconductor resistor, is installed on the throttle on the same axis as the throttle.

According to the signal from the sensor, the engine control unit determines the position of the throttle valve in order to calculate the duration of the electrical impulse supplied to the injectors and the optimal ignition timing.

The determining signal is the value of the voltage drop across the variable resistor of the sensor, which varies depending on the position of the throttle valve (fully closed, partially open, fully open).

When a sensor fails, the engine control unit operates according to the backup program stored in ((memory)) using data from other sensors. At the same time, the control lamp in the instrument cluster lights up.

The speed and timing sensor is located at the front of the engine on the right side.

According to the signal from the sensor, the engine control unit determines the angular position of the crankshaft and its speed.

According to the frequency of the signals generated by the sensor during the rotation of the synchronization disk mounted on the crankshaft pulley, the control unit determines the number of revolutions of the engine crankshaft, synchronizing the fuel supply by the injectors and the ignition timing with the engine's working process.

If the crankshaft position sensor fails, the engine will not start, because the control unit, without receiving a signal from the sensor, will not turn on the injection and ignition systems.

The knock sensor is located on the top of the engine block on the right side and is secured with a nut and spring washer.

It is used to determine the moment of detonation when the engine is running on gasoline with a lower than required octane number when the engine overheats, the driver chooses the wrong driving mode.

The knock sensor is based on the principle of the piezoelectric effect.

When a piezoelectric element made of cermet is mechanically acted upon, an electric current arises in it.

The mechanical action is carried out by an inertial washer, which perceives the shock wave that occurs in the combustion chamber and engine cylinder during detonation combustion of the fuel mixture.

In this case, a voltage pulse occurs in the sensor, which it transmits to the control unit from the plug.

According to this signal, the control unit corrects the ignition timing until detonation stops.

Failure sensor or a malfunction in its electrical circuit will result in the lack of optimal ignition timing in the presence of detonation. At the same time, the indicator lamp in the instrument cluster will light up.

The phase sensor is located at the rear of the cylinder head on the left side.

The principle of operation of the sensor is based on the Hall effect.

When a metal plate attached to the camshaft passes by the end of the sensor core, an impulse is generated that allows the control unit to determine the moment of location

piston of the 1st cylinder at top dead center during the compression stroke and apply an injection signal to the nozzle of this particular cylinder.

Further supply of impulses is carried out by the control unit in accordance with the order of operation of the cylinders laid down in its program.

If the phase sensor fails, the control unit switches to standby mode with fuel supply to all cylinders simultaneously. At the same time, engine performance is maintained, but fuel consumption is significantly increased.

A malfunction of the sensor is signaled by a warning lamp in the instrument cluster.

An air filter with a dry replaceable filter element made of corrugated filter paper is located in the right front of the engine compartment.

The filter element is fixed on the filter cover with a wing nut, and the cover is fixed on the body with three spring clips.

Electric fuel pump of rotary type driven by a DC motor is located directly in the pump housing and works in the fuel.

In this regard, there are no seals of moving parts in the pump, and the rubbing surfaces are lubricated by flowing fuel.

A non-return valve installed in the pump prevents fuel from flowing from the high pressure fuel line into the tank after the ignition is turned off.

The electric fuel pump is a non-separable design and must be replaced if it fails.

The fuel filter is installed in the engine compartment above the vacuum brake booster.

Replacing the standard filter with some other, for example, unified, in a plastic case, is strictly prohibited due to the high fuel pressure in the system.

Crankcase ventilation system of a closed type, forced, acting due to vacuum in the intake pipeline.

When the engine is idling and at low loads, when the throttle is closed, crankcase gases are sucked through the hose of the small branch of the system directly into the engine intake pipe and then into the cylinders.

In other modes, the exhaust of crankcase gases is carried out through the hose of the main branch of the system into the throttle and from there into the intake pipeline.

During operation, it is necessary to monitor the tightness of the connection and the cleanliness of the pipelines, since when the crankcase ventilation system is not working, the oil in the engine quickly oxidizes and ages.

Clogging of the system pipelines leads to oil leakage through the oil seals and engine seals due to an excessive increase in the pressure of crankcase gases.