The cylinder block is cast in gray cast iron.

There are coolant channels between the cylinders

Cylinders are made without insert sleeves.

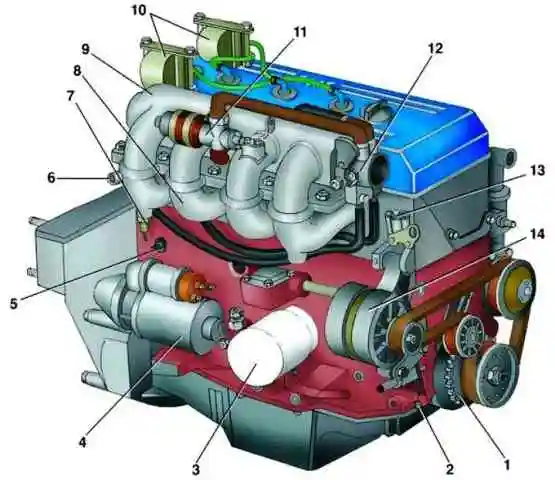

Type of engine mod. 4062 on the right side: 1 - synchronization disk; 2 - speed and synchronization sensor; 3 - oil filter; 4 - starter; 5 - knock sensor; 6 - coolant drain pipe; 7 - air temperature sensor; 8 - inlet pipe; 9 - receiver; 10 - ignition coil; 11 - idle speed regulator; 12 - throttle; 13 - hydraulic chain tensioner; 14 - generator

There are five crankshaft main bearings at the bottom of the block.

The main bearing caps are made of ductile iron and are attached to the block with two bolts.

The bearing caps are bored together with the block, so they cannot be interchanged.

On all covers, except for the third bearing cover, their serial numbers are stamped.

The cover of the third bearing, together with the block, is machined at the ends to install thrust bearing half washers.

The chain cover and stuffing box with crankshaft seals are bolted to the ends of the block.

The oil sump is attached to the block from below.

At the top of the block is a cylinder head cast from an aluminum alloy. It has intake and exhaust valves.

There are four valves per cylinder, two intake and two exhaust.

The intake valves are on the right side of the head, and the exhaust valves are on the left.

The valves are driven by two camshafts through hydraulic tappets.

Maintenance and repair of the engine are described in the articles:

Camshafts of the ZMZ-406 engine

Checking and replacing nozzles ZMZ-406

Checking and replacing sensors ZMZ-406

Checking and replacing the synchronization sensor ZMZ-406

Checking engine compression ZMZ-406

Diagnostics of the engine management system ZMZ-406

Engine management system ZMZ - 405, 406

High-voltage wires and candles ZMZ-406

How to check the camshaft sensor ZMZ-406

How to replace valve stem seals ZMZ-405, ZMZ-406

Hydraulic chain tensioner ZMZ-406

Ignition system with 406 engine

Microprocessor ignition system ZMZ-406

Possible malfunctions of ZMZ-406

Repair of the cylinder head ZMZ-405, ZMZ-406

Replacement of crankshaft oil seals ZMZ-406