Checking and adjusting the valve clearance must be done on a cold engine (coolant temperature 20˚С), with the cylinder head mounted on the block

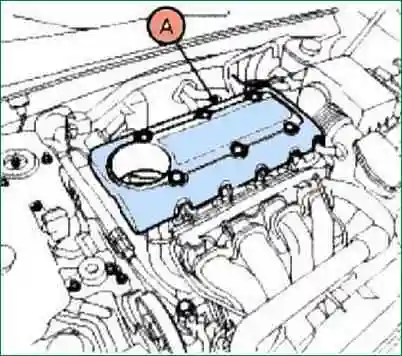

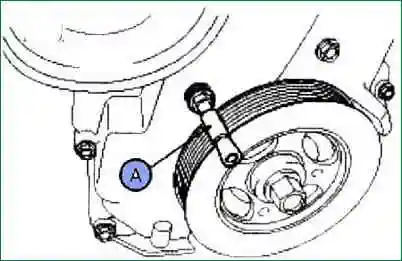

Remove the engine cover (A).

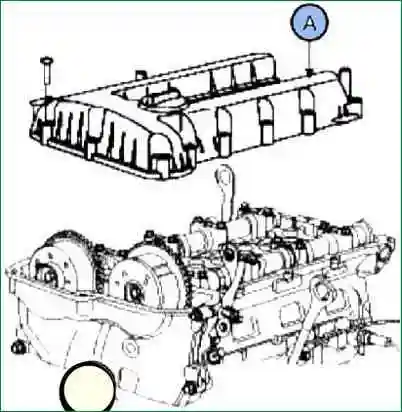

Remove the cylinder head cover.

- - Disconnect the ignition coil connector and remove the ignition coil.

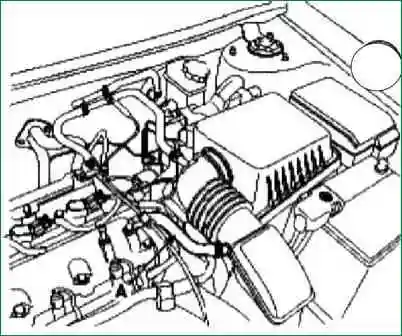

- - Disconnect the R.C.U. cable (crankcase ventilation) (B).

- - Disconnect the ventilation hose (A).

- - Loosen the mounting bolts and remove the cylinder head cover (A) together with the gasket.

Set the piston of the first cylinder to top dead center on the compression stroke. For this:

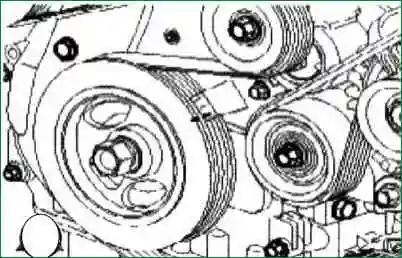

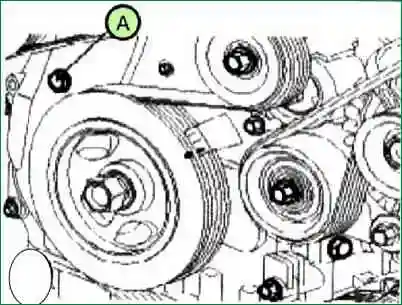

- Turn the crankshaft pulley and align the selection on the pulley with the "T" mark on the plate, as shown in the figure.

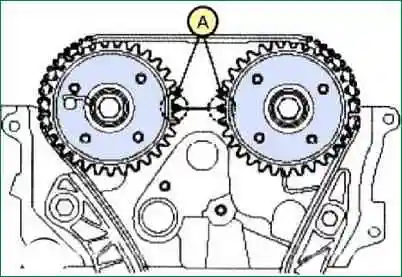

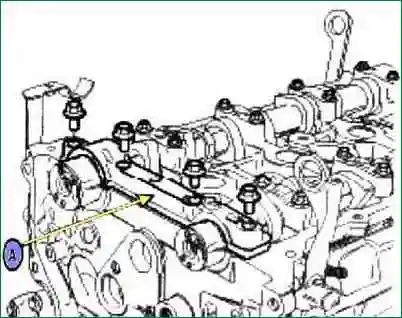

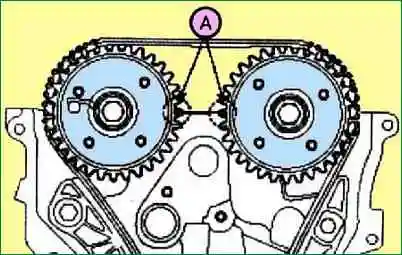

- Check and make sure that the mark on the camshaft sprocket (A) is aligned in a straight line with the surface of the cylinder head.

If the hole does not match the mark, rotate the crankshaft 360˚.

Measure the valve clearance. For this:

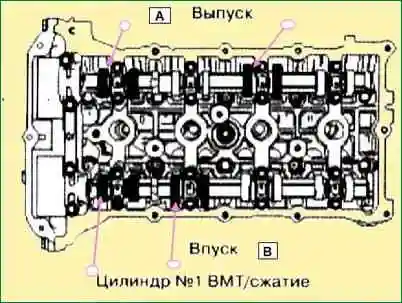

- - Check the valve marked in the picture (cylinder #1, TDC/compression). Measure valve clearance.

- - Use a feeler gauge set to measure the gap between the cam and the main circumference of the camshaft.

Record your measurements. They will be needed to determine the required position of the replaced cam. Engine coolant temperature 20˚С.

Maximum clearance:

- 0.10 - 0.30 mm (inlet),

- 0.20 - 0.40 mm (outlet).

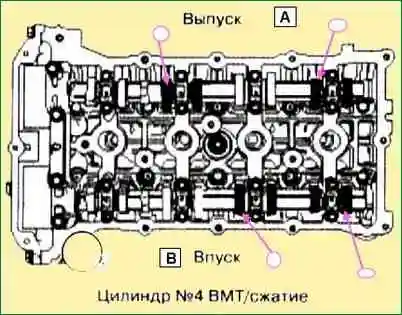

- - Rotate the crankshaft pulley 360˚ and align the groove with the “T” mark on the lower timing chain cover.

- - Check the valves marked in the picture (cylinder #4, TDC/compression). Measure the valve clearance.

Adjust the clearance in the exhaust and intake valves. For this:

- - Set the piston of cylinder No. 1 to TDC on the compression stroke.

- - Put a mark on the timing chain and camshaft sprockets.

- - Remove the bolt (A) of the service hole of the timing chain cover. (The bolt can only be installed once).

- - Insert the special tool into the service hole of the timing chain cover and release the ratchet.

- - Remove the front bearing cover (A) of the camshafts.

- - Remove the exhaust camshaft bearing cap and exhaust camshaft.

- - Remove the intake camshaft bearing cap and intake camshaft.

Hold the timing chain while disconnecting from the camshaft sprocket.

- - Fix the timing chain by linking it.

Be careful not to drop the parts inside the timing chain cover.

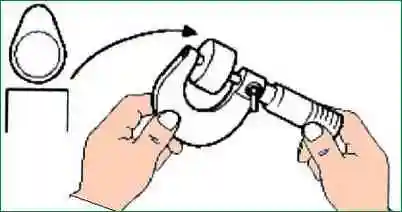

- - Measure the thickness of the removed cam using a micrometer.

- - Calculate the thickness of the new cam, the value should not exceed the standard one

Valve clearance (at 20°C engine coolant temperature). T is the thickness of the removed cam, A is the measured valve clearance, N is the thickness of the new cam.

- Inlet: N = T + [A - 0.20 mm].

- Outlet: N = T + [A - 0.30 mm].

- Select the thickness of the new cam as close as possible to the standard value.

The gasket size should be between 3 and 3.69 ± 0.015 mm, size number 47.

- - Install a new cam on the cylinder head.

- - holding the timing chain, install the intake camshaft and timing chain sprocket.

- - Align timing chain marks and camshaft sprocket.

- - Install intake and exhaust camshafts.

- - Install the front bearing cap.

- - Install the service hole bolt. Tightening torque 11.8 - 14.7 Nm.

- - Rotate the crankshaft 2 turns clockwise and move the marks (A) of the crankshaft and camshaft sprocket.

- - Check the valve clearance again.

Valve clearance (at engine coolant temperature: 20˚ C).

- Inlet: 0.17 - 0.23 mm.

- Outlet: 0.27 - 0.33 mm.