Reinforced version of the ZIL-5301 clutch

Since April 2001, a reinforced version of the clutch has been installed on vehicles.

The damper part of the driven disk has been reinforced: the damper springs are vulcanized with rubber and look like a rubber cylinder

Asbestos-free friction linings are used (asbestos friction linings can be installed).

To reduce wear of the friction linings and improve the smoothness of clutch engagement, an elastic fastening of one lining to the driven disk from the short part of the driven disk hub has been introduced.

The thickness of the working part of the disk in a free state has increased to 11.6 mm instead of 9.8 mm.

The outer diameter of the driven disk has not changed - 340 mm.

Externally, reinforced driven disks can be distinguished from disks of the previous design by rubberized damper springs, greater thickness of the working part and the presence of additional elastic plates between the lining and the metal driven disk, as well as the location of the rivets of the friction linings.

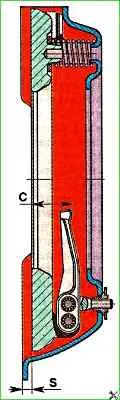

In the pressure plate with the casing assembly, the amount of movement has been increased. pressure plate by changing the adjustment of the lever position (Fig. 1), the size has been increased from 40.2 to 44 mm, and springs with increased force have been installed to transmit increased torque.

They differ from the previously installed springs in their greater length in the free state - 65 mm instead of 63 mm and the load when compressing the spring to a spring height of 45 mm - 735 ÷ 815 N instead of 628 ÷ 736 N.

The designation of the pressure plate with the casing has remained unchanged - 130-1601090 and it can be installed on cars of previous releases together with driven disks 130-1601130 or 431900-1601130.

One washer 3250-1601127 is installed under the clutch mounting bolts between the casing and the flywheel 1 mm thick (8 pcs. per set), the bolts do not need to be changed.

On previously manufactured vehicles, a reinforced driven clutch disc can be installed (driven disc designation - 3250-1601130). To do this, you need to:

- - change the adjustment of the pressure plate levers - 44 mm instead of 40.2 mm;

- - install washers 3250- 1601127 between the flywheel and the pressure plate casing;

- - replace the existing clutch release fork lever - 494560-1602043 with the 3250-1602043 lever;

- - replace the existing pneumatic hydraulic booster mounting bracket 5301-1606621 or 5301-1609621-01 with the bracket - 3250-1609621;

- - adjust the free play of the clutch release fork lever, measured along the axis of the connecting pin within 5-6 mm.

ATTENTION!

When installing the driven disk, the short part of the hub should be facing the pressure plate and gearbox.

In stores, you should ask for a disk from "Zubrenok" and install it, as practice has shown, it is the most durable.