If during the next maintenance or when changing a wheel it is found that the wear of the pads has exceeded the standards specified in the table, then it is necessary to change the pads

The pads must be changed as a set on one axle, regardless of the fact that one wheel has less wear than the other.

Removal

Place the car on a lift or lift it with a jack.

Remove the front wheels.

Clean the front brake parts with a wire brush.

Use a flat-head screwdriver to spread the pads, while unscrewing the cap of the reservoir on the master cylinder and monitoring the brake fluid level.

If the level increases above the norm, it can be removed with a syringe.

For cars with a K7M engine

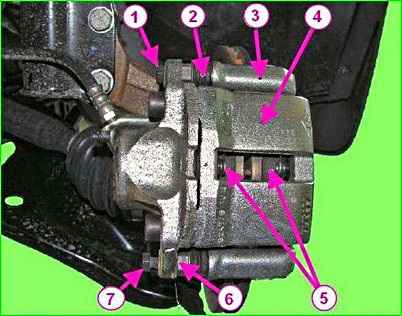

Unscrew and remove the lower bolt 7, Figure 1, securing the guide pin, holding the guide pin 6 with a wrench (17 spanner, 13 replaceable head, ratchet wrench).

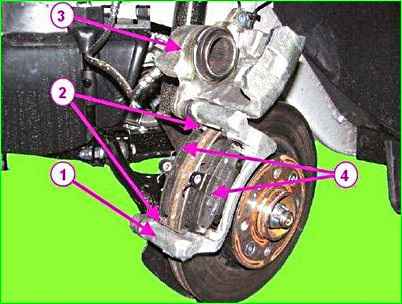

Turn the caliper 3, figure 2, upward and remove the brake pads 4 and noise-suppressing plates 2.

For cars with the K4M engine

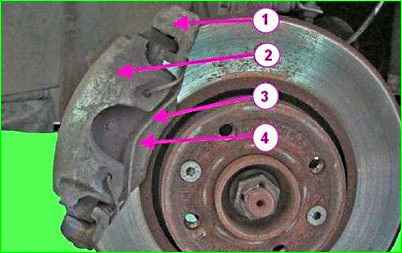

Remove spring 3, figure 3, from the holes in front brake caliper 2 (flat-head screwdriver, pliers).

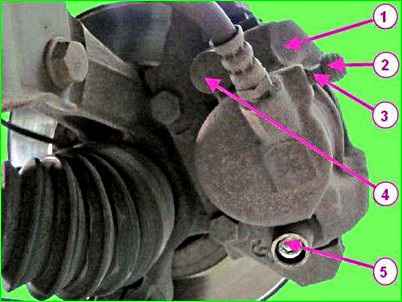

Using a flat-head screwdriver, remove the protective caps 4, Figure 4, from the guide pin wells.

Using a 7 mm Allen key, unscrew and remove the guide pins 5.

Remove and hang the front brake caliper on the suspension spring.

Be careful with the brake hose so as not to stretch or twist it.

Remove the front pads.

Table 1. Parameters of brake pads

Nominal thickness of brake pads (including backing):

- - engine model K7M - 18.0 mm;

- - engine model K4M - 17.7 mm

Minimum permissible thickness of brake pads (including backing) - 6.0 mm

Installing pads

Check the thickness of the brake pads in accordance with table 1 and replace if necessary.

Check the condition of the dust cap of the working piston, dust covers of the guide pins and replace if necessary.

For cars with the K7M engine

After removal, bolts 1, Figure 1, fastening the guide pins must be replaced, since the bolts are fixed adhesive compound applied to the threaded surface of the bolt. Reuse of bolts is not allowed.

When replacing the pads, replace the noise-suppressing plates 2, Figure 2.

Install new noise-suppressing plates in the front brake guide, install the brake pads.

Turn the caliper down and secure it with the guide pin mounting bolt, first apply 1 g of Frenetanche adhesive to the threaded part of the bolt. Tightening torque of the bolt 34 Nm (3.4 kgf.m) (17 spanner, 13 replaceable head, ratchet wrench, torque wrench).

For cars with K4M engine

Install the brake pads in the front brake guide.

Install the front brake caliper on the guide and secure it with the guide pins. Tightening torque of guide pins 28 Nm (2.8 kgf.m).

Install protective caps in guide pin wells.

Install spring in caliper holes (pliers, flat screwdriver).

Install front wheels.

Press brake pedal 2-3 times, check and adjust if necessary and the brake fluid level in the brake hydraulic reservoir to the norm. Install the brake fluid reservoir cap.

Check the efficiency of the working brake system.