The piston pins are installed with tension in the upper heads of the connecting rods and rotate freely in the piston bosses, so heat the upper head of the connecting rod to a temperature of 250˚ C

During assembly, it is convenient to use the Mot. 574-22 kit and the Mot. 574-24.

Disassembly and inspection of the K4M engine CPG was discussed in the article - "Disassembly and defect detection of the CPG".

Visually check the condition of the connecting rods (twisting and bending) and the cleanliness of the bearing surfaces of the cover and the crank head of the connecting rod.

To heat the upper head of the connecting rods, use an electric stove with a power of 1500 W.

Place the upper heads of the connecting rods on the stove.

Make sure that the upper heads of the connecting rods touch the stove over the entire surface.

Put a piece of tin solder on each head of the connecting rod as a temperature indicator.

The melting point of tin solder is approximately 250 ° C.

Heat the upper heads connecting rods until the solder melts.

Preparing the piston pins

Check that the piston pins rotate freely in the bosses of the corresponding new pistons.

For installation, use the C13 and A13 mandrels from the Mot. 574-22 kit for piston pins without a flange or the C13 and A13 mandrels from the Mot574-24 kit for piston pins with a flange.

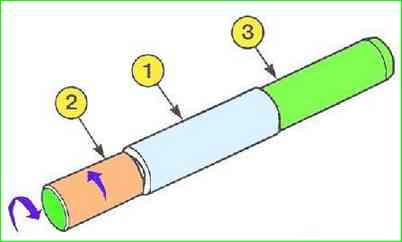

Install the piston pin (1) on the mounting mandrel (2) (see Fig. 1).

- - Tighten the mandrel (3) until the assembly is tightened.

- - Loosen the mandrel (2) a quarter of a turn.

Position of the pistons in relation to the connecting rods

The pistons are marked with a "V" mark on the head, which should be located on the flywheel side.

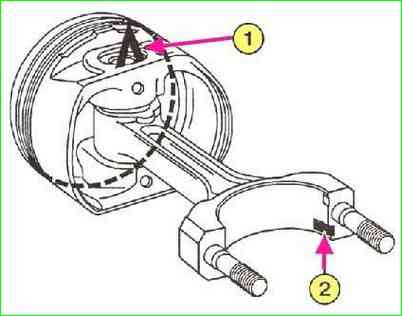

- - Position the piston head with the "V" mark facing up (see 1, Fig. 2).

- - Direct the groove for the connecting rod bearing retaining tab downwards (see 2, Fig. 2).

Assembly

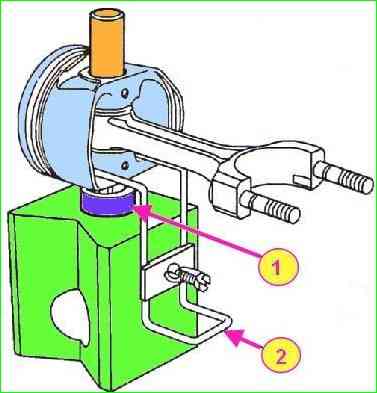

Install the "B10" ring (see 1, Fig. 3) on the prism, the piston with the support on the ring and fasten all the parts with a clamp (2).

Make sure that the piston pin hole matches the "B10" ring hole.

Lubricate the mandrel and the piston pin with engine oil.

Leave the piston pin in the assembly and check if it rotates freely. If necessary, center the piston.

The following operations must be performed quickly to prevent the connecting rod head from cooling.

When the solder piece has melted, remove the solder.

Insert the centering mandrel into the piston,

Insert the correctly oriented connecting rod into the piston.

Quickly press the piston pin until the centering mandrel stops at the bottom of the fixture.

Make sure that the piston pin does not protrude from the piston in any position of the connecting rod.

Installing the piston rings

The piston rings are matched to the piston and must move freely in the piston grooves.

Observe the direction of installation of the rings (the "TOP" mark must be facing up).

Observe the position of the lock of each ring (see Fig. 4). The locks of the compression rings must be rotated by 180˚, the locks of the oil scraper ring parts - by 120˚.