After removing the engine from the car and removing the cylinder head, you can begin disassembling, repairing and assembling the engine cylinder block

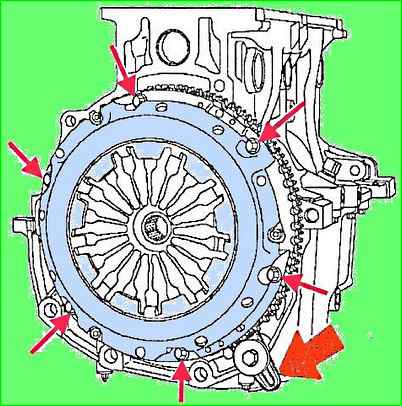

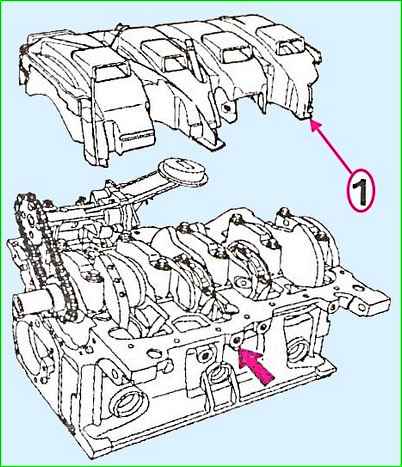

Install the Mot582-01 or Mot1677 flywheel lock (see arrow in Fig. 1).

Remove the pressure and driven clutch discs.

It is recommended to mark the relative positions of the clutch basket and flywheel, so that during assembly there are no problems with their balancing, this is especially important during subsequent assembly of these same parts.

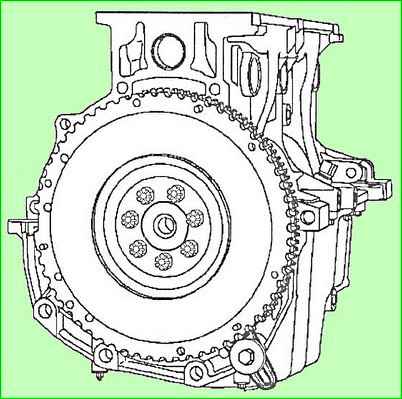

Remove the flywheel (see Fig. 2). It is recommended to mark the flywheel position on the crankshaft flange,

these two parts are balanced as an assembly, so a different relative position may disrupt the balance, especially if repair or replacement of these parts is not envisaged.

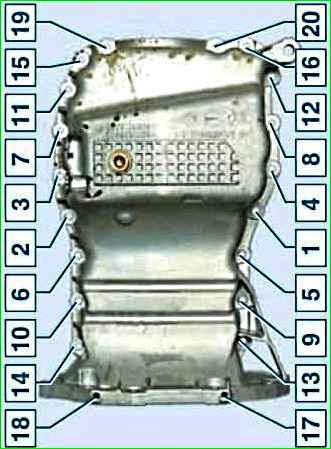

Unscrew and remove the engine oil pan (see Fig. 3).

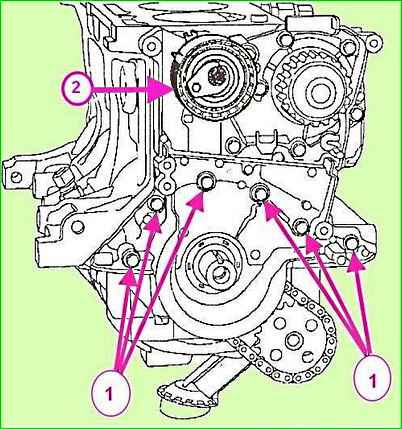

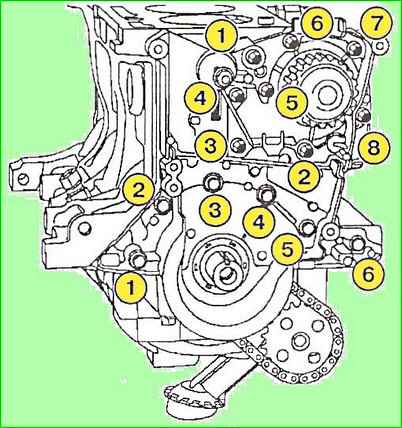

Remove the timing belt tension roller (see Fig. 4).

Unscrew the bolts and remove the water pump (Figure 5)

Remove the front cover of the engine block.

Remove the oil level sensor (see arrow, Fig. 6), oil separator (pan).

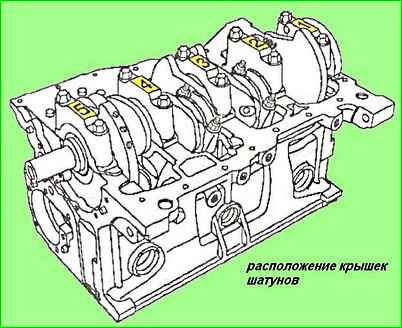

Mark the upper part of the connecting rod and its cover with a marker.

It should be noted that the bearing shells do not have a bent guide lug, but the groove for the lug on the connecting rod is there and serves to orient the connecting rod relative to the piston.

To facilitate assembly, mark the side of the connecting rod facing the flywheel.

Note. Do not use a center punch or engraving machine to mark the top and cap of the connecting rod, as this may cause subsequent destruction of the connecting rod during operation.

Use a permanent marker.

Unscrew the connecting rod cap fastening nuts (see Fig. 7) and carefully remove the connecting rod caps with bearing shells.

Remove the pistons with connecting rods as an assembly, the oil pump drive chain and the oil pump. Set aside the second connecting rod bearing shells.

Note. Remove the pistons with connecting rods toward the cylinder head, wrapping the lower connecting rod head with tape to avoid scratching the cylinder walls.

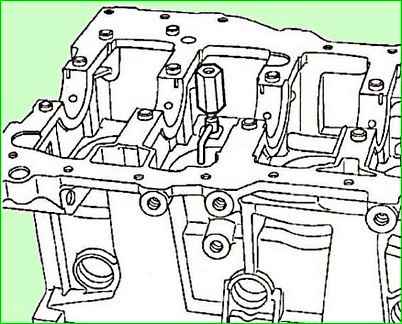

Remove the crankshaft main bearing caps (the bearing caps are numbered 1 through 5) (see Fig. 7).

Remove the main bearing shells from the caps.

Note. Be sure to mark the main bearing shells and crankshaft supports, as liners of different sizes can be installed on one engine.

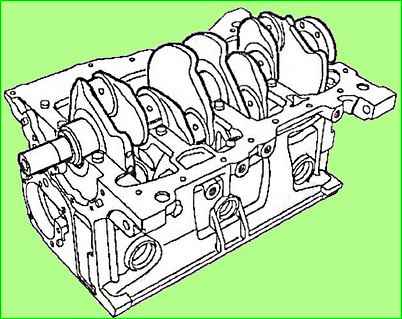

Remove the crankshaft (see Fig. 8) and take out the lower bearing shells.

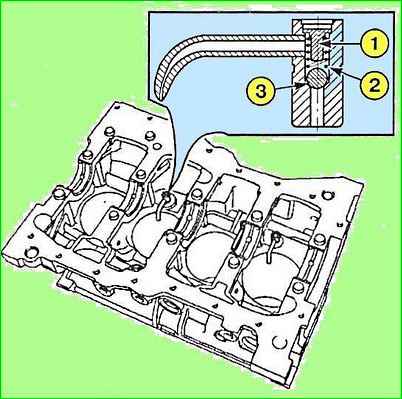

Removing the piston cooling nozzles

The nozzles are used to supply a stream of oil from below to the piston bottoms, this enhances piston cooling during operation, which made it possible to reduce their weight and increase effective engine power.

The injectors can only be removed by destroying them, otherwise there will be no supporting surface for the puller.

When assembling, you will have to replace the injectors ki new ones.

On the other hand, without removing the injectors, it is impossible to clean the engine oil supply channels to the injectors.

With poor maintenance and cheap engine oil, this can lead to a decrease or even cessation of the supply of engine oil to cool the pistons, which is fraught with melting of the pistons during operation.

Drill out the piston cooling nozzle housing from above with a 7 mm drill, remove the rolled edge holding the plug (1) (see Fig. 9).

Do not remove the ball (3) to prevent chips from getting into the oil channel (see Fig. 9).

- - Remove the plug (1) and spring (2).

- - Remove metal filings with a brush.

Screw the adapter Mot1485 or Mot1485-01 into the injector (see Fig. 10).

- - Screw the inertial puller Emb880 into the adapter.

- - Remove the injectors using the inertial puller.

Cleaning the lower part of the engine

Clean the following components with Decapjoint to dissolve adhering gasket residues:

- - cylinder block;

- - crankshaft;

- - engine oil sump;

- - front cover of the engine block;

- - crankshaft main bearing caps.

Apply composition on the surface to be cleaned, wait about 10 minutes, then remove it with a wooden spatula.

Do not clean the mounting surfaces of aluminum parts with tools with a sharp edge.

Do not allow the cleaning agent to come into contact with paintwork.

Clean carefully, do not allow dirt to get into the channels supplying oil to the hydraulic tappets and camshafts (the channels are located in the cylinder block and the cylinder head), and the oil drain channels.

If this requirement is not met, the oil supply channels may become clogged, which will lead to rapid engine failure.

Blow out all oil channels with compressed air, if the channel is blocked, clean it with soft wire and rinse with special agents.

Next, prepare all the parts for inspection and defect detection.

After that, assemble the engine. These points will be discussed in the following articles.