After preparing the units and parts for assembling the cylinder block, we proceed to assembly

Assembling the connecting rod with the piston is discussed in the article - "Assembling the piston"

Defect detection of the block and crankshaft was discussed in the article - "Preparing the block and crankshaft".

Installing piston cooling nozzles

New nozzles must be carefully pressed into the holes of the cylinder block, this operation is complicated by the fact that the nozzles are small, and access to the mounting holes is difficult, so we recommend using devices.

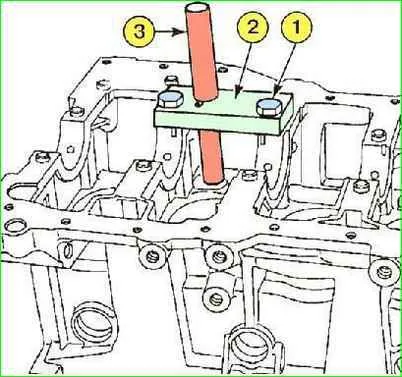

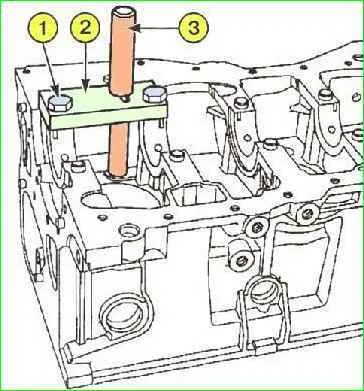

Install the plate (2) of the Mot.1494 device on the cylinder block, without tightening the two mounting bolts (1) (see Fig. 1 and 2).

When installing injectors for cylinders 1 and 3, use the left hole in the support (1) Figure 1.

When installing injectors for cylinders 2 and 4, use the right hole (Figure 2). Everything else is done in the same way.

Install the jig (3) in the plate (2). To center the plate, the end of the jig must enter the hole for the injector.

- - Tighten the two mounting bolts (1).

- - Remove the jig (3).

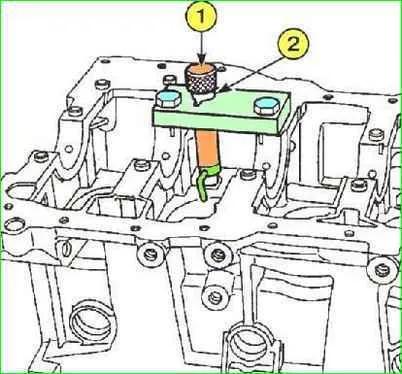

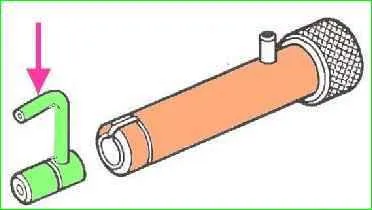

- Install the mandrel (1) instead of the jig (see Fig. 3). Insert the injector into the mandrel.

Note. Pay attention to the direction of installation of the nozzle, the nozzle tip should be directed towards the center of the cylinder (see arrow, Fig. 4).

- Hit the mandrel several times with a hammer until the flange (see 2, Fig. 3) of the mandrel touches the support.

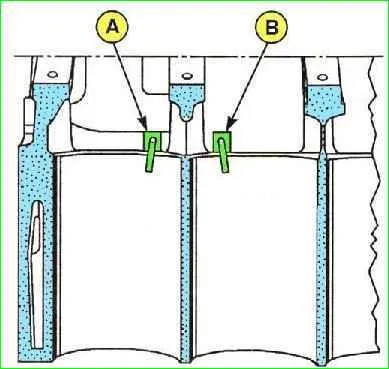

Check that the piston bottom cooling nozzles are oriented correctly. Mark "A" corresponds to the injectors of cylinders 2 and 4, and mark "B" corresponds to the injectors of cylinders 1 and 3 (see Fig. 5).

Crankshaft bearing shells

Reuse of crankshaft bearing shells is not recommended.

During operation, hard wear particles are embedded in the soft layer of the liners, such liners subsequently accelerate the wear of the crankshaft journals.

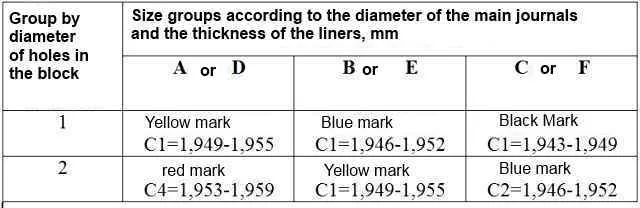

Selection of main bearings

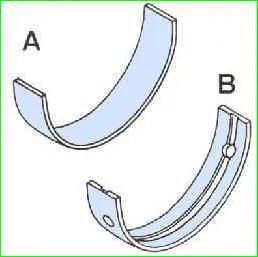

The engine is equipped with liners (see Fig. 6) without guiding elements (without a guide "whisker").

The liners are installed using the Mot1493-01 device.

Main bearing shell dimensions

Installation

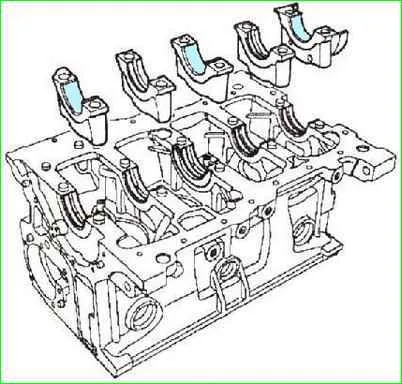

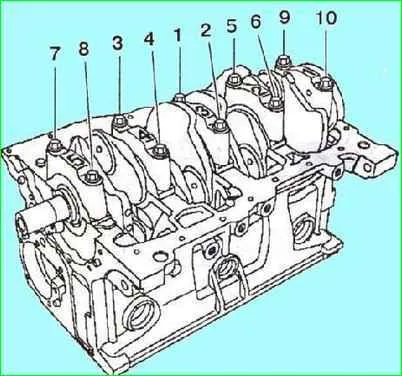

- - Install grooved liners in all cylinder block beds (see Fig. 7).

- - Install the liners with grooves in the caps of main bearings 2 and 4, and the liners without grooves in the caps of main bearings 1, 3 and 5.

At the factory, a guide tool is used to install the main bearing shells (see Fig. 8).

The liner is placed in the tool and fed inward until the front edge of the liner stops against the projection of the tool.

Checking the clearance in the main bearings

Do not turn the crankshaft under any circumstances when checking the clearance.

- - Remove any remaining oil from the main journals and cylinder block supports.

- - Install the crankshaft and crankshaft thrust half rings on the 3rd support (with the grooves facing the crankshaft cheeks).

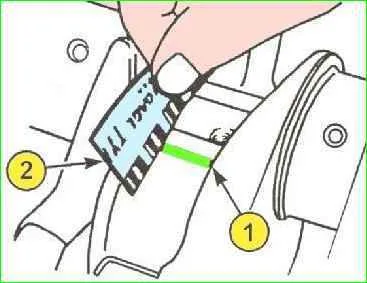

- - Cut several pieces of calibrated plastic wire from a roll (see 1, Fig. 9).

- - Place the wire along the axis of the crankshaft main journals (outside the area of the bearing lubrication holes).

- - Install the crankshaft main bearing caps in their proper places (see Fig. 10).

- - Tighten the crankshaft main bearing cap bolts to the specified order. In this case, the plastic wire will be crushed - it will occupy the entire gap between the liner and the crankshaft journal.

- - Remove the main bearing caps and take the crankshaft out of the bed.

- - Using the width of the flattened calibrated wire, using the standard template, determine the gap between the liners and the main journals (2) (see Fig. 10).

- - Check the gap size, which should be 0.027-0.054 mm.

- - Clean the crankshaft and main bearing shells from the remains of the calibrated wire.

Checking the axial clearance of the crankshaft

- - Lubricate the crankshaft main bearing shells with engine oil. Only the surface facing the crankshaft journal is lubricated.

- - Install the crankshaft.

- - Check for the presence of thrust half rings on the 3rd support (the grooves of the half rings should be facing the crankshaft cheeks).

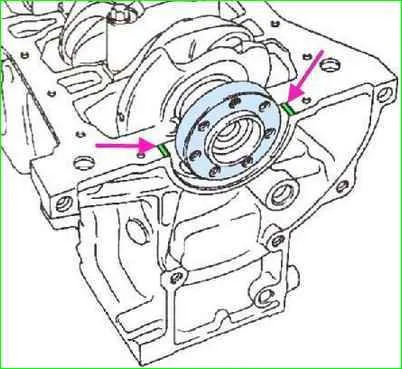

The seating surfaces of the cylinder block support and the main bearing cap No. 1 must be clean, dry, and free of oil.

Excess sealant will be squeezed out when tightening the parts.

If drops of hardened sealant get into the oil or coolant, some components and assemblies (engine, radiator, etc.) may clog.

- - Apply Rhodorseal5661 in 1 mm wide stripes (see arrow, Fig. 11).

- - Install crankshaft main bearing caps, installing cap No. 1 on the flywheel side (see Fig. 10).

- - Tighten crankshaft main bearing cap bolts in the specified order.

- - Check crankshaft axial travel, which should be:

- - new half rings, mm. 0.045—0.252;

- - old half rings, mm. 0.045—0.852.

- - Check the ease of rotation of the crankshaft.

Installing the connecting rod bearing shells

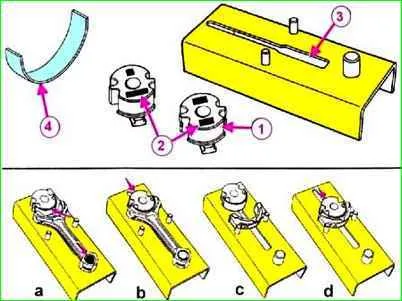

The engine is equipped with smooth shells without guide tabs (see 4, Fig. 12).

The shells are installed using the Mot1492 tool.

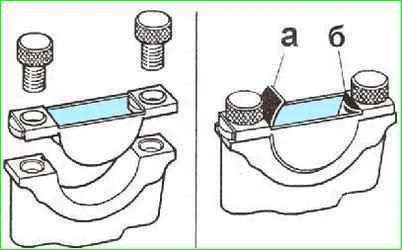

- - Select the mandrel (1) according to the engine model (see the marks (2) for the engine model).

- - Install the mandrel in the housing groove (3).

- - Install the connecting rod on the Mot tool. 1492.

- - Place the upper connecting rod head on the support pin and press the connecting rod in the direction of the arrow (a).

- - Install the bearing shell on the mandrel.

- - Feed the mandrel with the bearing shell into the lower connecting rod head (b).

- - Remove the mandrel from the connecting rod head and repeat the operations with the remaining connecting rods.

- - Install the connecting rod cap on the housing pins.

- - Install the connecting rod bearing shell on the mandrel (c).

- - insert the mandrel with the insert into the connecting rod cap (d).

- - Remove the mandrel from the connecting rod cap and assemble the remaining connecting rod caps in the same way.

Assembly of connecting rods with pistons and installation of rings, is discussed in the article - "Assembly of the connecting rods"

Tightening torques of fasteners

Unit - Tightening torque, Nm

- Bolts for fastening the crankshaft main bearing caps 20+62˚±4˚

- Bolts for fastening the connecting rod caps 20+40˚±6˚

- Bolts for fastening the water pump cover 15

- Bolts for fastening the water pump 17

- Bolts for fastening the pulley water pump 20

- Idler pulley mounting bolt 50

- Oil calmer and oil pump bolts 24

- Oil pan mounting bolts 14

- Oil level sensor 16-24

- Oil filter nipple (without cooler) 10-20

- Oil filter nipple (with cooler) 55-60

- Knock sensor 20

- Oil pressure sensor 30

- Oil filter 10-14

- Coolant supply line mounting bolts 9

- Conventional flywheel mounting bolts 50-55

- Dual damping flywheel 18-22, +50˚±6˚

- M6 bolts for fastening the clutch housing 15±10%

- M7 bolts for fastening the clutch housing 20±10%

- M8 bolts for fastening the clutch housing 25±10%

Continuation of the article on the assembly of the K4M cylinder block in the next article.