Automatic transmission disassembly should be carried out in a place protected from dust. When disassembling, it is necessary to check the condition of the parts for wear and damage.

Only plastic hammers should be used to separate the crankcase parts

Do not use rags when disassembling: rag fibers can clog the fluid channels. Some parts are similar to each other, so when disassembling, arrange them so as not to mix them up.

If the clutch or brake band is burnt or the quality of the fluid in the box has deteriorated, then it is imperative to clean the valve block.

Before disassembling, you need to clean the outer surface of the box with a cleaner or solvent.

You need to clean the removed parts with a solvent and dry them with compressed air.

We install the gearbox on a special stand or workbench.

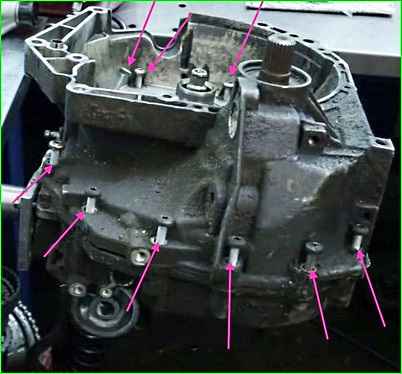

We unscrew the bolts securing the clutch housing to gearbox housing (Fig. 1)

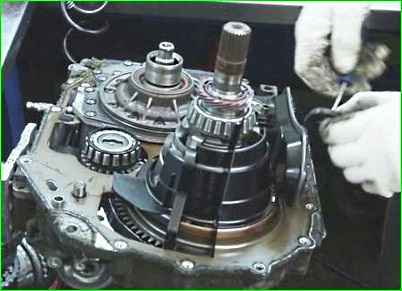

We separate the gearbox housing (Fig. 2)

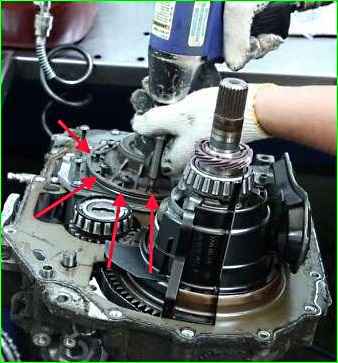

Remove the magnet from the automatic transmission filter (Fig. 3)

Unscrew the pump (Fig. 4)

Remove the pump and separate the filter from it (Fig. 5)

Disassemble the pump, remembering the position of the parts, and determine their wear (Fig. 6)

Removing the gearbox housing gasket (Fig. 7)

Removing the differential (Fig. 8)

Remove the parking lever (parking pawl) (Fig. 9)

Using thin pliers, remove the band brake servo piston (Fig. 10)

Remove the first and second gear brake band (Fig. 11)

Remove the first and second gear drum (Fig. 12)

Removing the secondary shaft (idler gear) (Fig. 13)

Turn the transmission over and unscrew the screws securing the hydraulic unit pan (Fig. 14)

Remove the hydraulic unit pan and inspect the magnets for chips (Fig. 15)

Unscrew the valve body mounting screws (Fig. 16)

Remove the valve body plate, the valve body itself (Fig. 17) and the sealing gaskets

Continued in the next article - "DPO Automatic Transmission Disassembly"