We have considered disassembling the gearbox in the article: - "Disassembling the gearbox"

After we have washed and inspected the gearbox parts, we proceed to assembly.

We have already installed the bearings and differential.

We simultaneously install the secondary shaft assembly, the first and second gear shift fork and the primary shaft (Fig. 1)

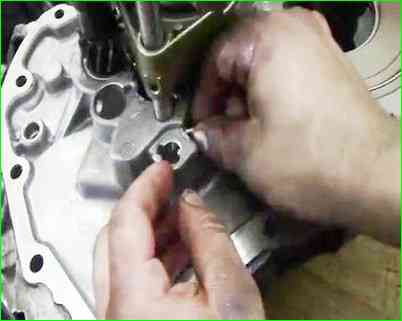

Install the retainers (bosses) in the sockets (Fig. 2)

Install the third and fourth gear forks (Fig. 3)

We hammer in the pin of the third and fourth gear forks (Fig. 4)

All forks must be in neutral, no gear engaged.

Installing the reverse clutch (Fig. 5)

Insert the fifth gear fork guide (Fig. 6)

Hammer in the reverse clutch locking pin (Fig. 7)

Before installing the gearbox housing, you need to engage third gear (Fig. 8)

This is necessary so that the leash, which is located in the housing (Fig. 9) installed in the third gear fork (Fig. 10)

Lubricate the joint of the crankcase with sealant (Fig. 11)

Put the magnet in a special pocket in the gearbox housing (Fig. 12)

Insert the oil gutter into the gearbox housing (Fig. 13)

Move the lever to the third gear position and begin installing the gearbox housing (Fig. 14)

- (This operation is performed by two people) At the beginning of installing the gearbox housing, the fifth gear rod comes out first. Before it comes out, insert the spring and the locking ball and hold it (Fig. 15).

At this time, the assistant lowers the gearbox housing.

The rod comes out of the hole in the housing and the locking ball the torus remains in place.

In the same way, we insert the clamps and the rod of the first and second speeds (Fig. 16)

Next, insert the retainer and the rod for III and IV gears (Fig. 17)

After connecting the housings, you need to check how the gears engage.

If all the gears engage, then the assembly was correct.

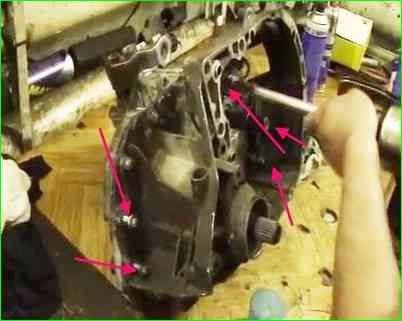

We bait and tighten the 16 bolts for fastening the gearbox housings (Fig. 18).

Before fully tightening the bolts, you need to turn the input shaft to adjust the bearings.

On the input shaft, install a thrust washer (the correct position of the sleeve is in Figure 8 of the article on disassembling the gearbox) and a gear sleeve (Fig. 19)

Install the fifth gear pinion together with the synchronizer and fork (Fig. 20)

Hammer the pin into the fifth gear fork (Fig. 21)

Put a lock washer (Fig. 22)

Fit and tighten the rear end of the primary shaft (Fig. 23) (tighten it with a torque of 190 Nm)

Install the fifth gear driven gear on the secondary shaft (Fig. 24)

We bait and tighten the bolt of the rear end of the secondary shaft (Fig. 25) (tightening torque 70 Nm)

Install a new sealing ring and install the rear cover of the gearbox housing (Fig. 26)

Tighten the three bolts of the rear cover.

Tightening torques of gearbox components:

- Unit – Tightening torque Nm

- Gearbox filler plug 3

- Gearbox housing to clutch housing fastening bolts 25

- Secondary shaft rear end bolt 70

- Primary shaft rear end nut 190

- Rear cover mounting bolts 25

- Reverse light switch 25

- Clutch slave cylinder mounting bolt 21

- Gear shift shaft mounting bolt 20

- Driver mounting bolt 10

- Reverse fork rod bracket mounting bolt 25

- Drain plug 25

- Gear shift shaft lock 21-23

- Gearbox housing to clutch housing mounting bolts with Loctite 63

- Other gearbox housing to clutch housing mounting bolts 52

- Main gear driven gear mounting bolts 120

- Reverse gear fork mounting bracket bolts 15