Install the car on a lift

Remove the crankcase guard and protective screen

Drain the liquid from the cooling system

Drain the oil from the gearbox

Drain the refrigerant from the refrigeration circuit using a refrigerant filling station.

Remove the noise muffler

Remove the air filter housing

Remove the battery

Remove the electronic control unit of the automatic transmission and the injection system ECU

Unscrew and remove the battery shelf

Unscrew and remove the front wheels of the car

Unscrew and remove the front wheel arch liners

Remove the front bumper

Tie the radiator to the upper cross member using a belt.

Remove the thrust rod

Remove the left front wheel drive shaft

Remove the front subframe

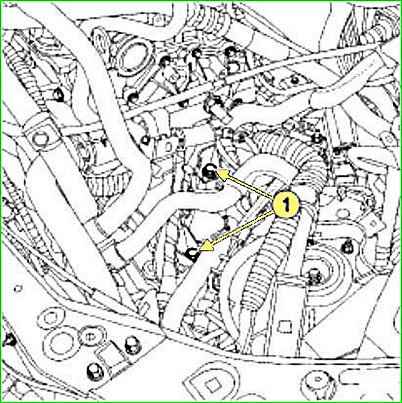

Unscrew the mounting bolts (1) of the engine wiring harness channel (Fig. 1)

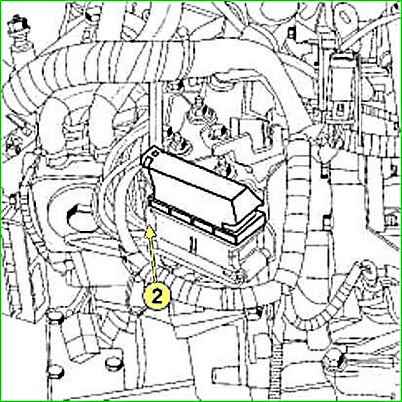

Disconnect the automatic transmission connector by pulling out the movable part (2), (Fig. 2)

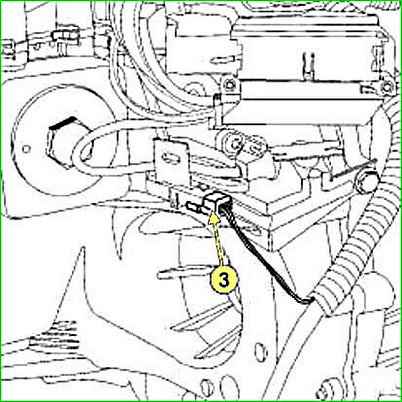

Disconnect the connector (3) from the electromagnetic valve for regulating the supply (Fig. 3)

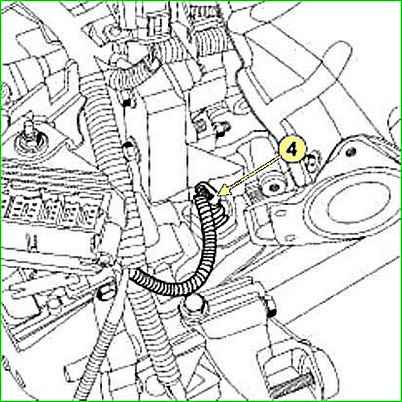

Disconnect the connector (4) from the tachometer

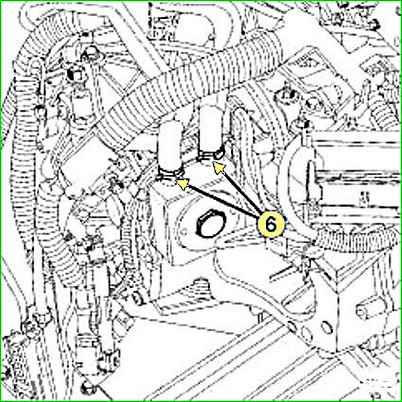

We loosen the clamps and disconnect the hoses (6) of the gearbox oil cooler (Fig. 5)

Remove the crankshaft position sensor

Unscrew and remove the engine starter

Through the hole for the starter, unscrew the torque converter mounting nuts (donut)

Next, remove the engine together with the gearbox, you can, of course, not remove the engine.

Remove the automatic transmission and immediately tie up the torque converter so that it does not disconnect (Fig. 6)

If remove the torque converter, it is necessary to take into account that it is quite heavy.

Disassembly of the automatic transmission is described in the article - Disassembly of the DPO automatic transmission.

Installation of the automatic transmission

When installing the automatic transmission, it is necessary to replace the torque converter mounting nuts

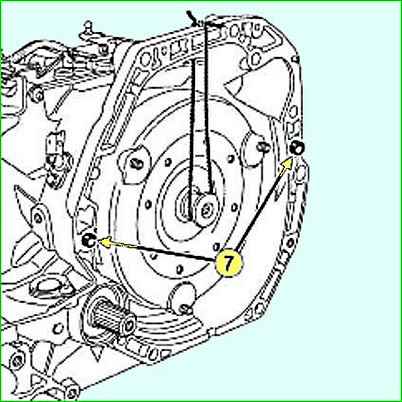

We check the presence of installation bushings (7) figure 7

We check the position of the torque converter in relation to the plane of connection of the engine with the gearbox.

We use a ruler for this, the value should be within (X) = 18.22 mm ± 1.

Before installing the gearbox, install the torque converter bolts opposite the holes in the drive disk.

Tighten to the required torque:

- - gearbox mounting bolts and nuts – 44 Nm

- - torque converter mounting nuts – 24 Nm.

Assemble all units and parts in the reverse order.