The Lada Largus is equipped with two independent braking systems: service and parking

The first, equipped with a hydraulic drive with a vacuum booster, provides braking when the car is moving, the second brakes the car when parked.

The service system is dual-circuit with a diagonal connection of the brake mechanisms of the front and rear wheels.

One hydraulic drive circuit ensures the operation of the right front and left rear brake mechanisms, the other - the left front and right rear.

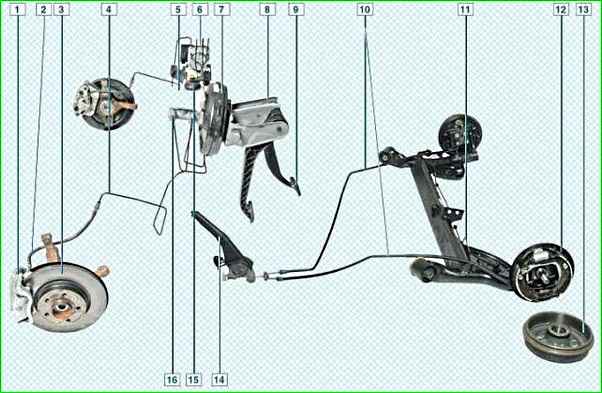

4x2 vehicle braking system components: 1 - floating caliper; 2 - front brake hose; 3 - front brake disc; 4 - front brake pipe; 5 - hydraulic fluid reservoir; 6 - ABS unit; 7 - vacuum booster; 8 - pedal assembly; 9 - brake pedal; 10 - rear parking brake cable; 11 - rear brake mechanism pipe; 12 - rear brake mechanism; 13 - rear brake drum; 14 - parking brake lever; 15 - low fluid level indicator sensor; 16 - brake master cylinder

If one of the circuits of the service brake system fails, the second circuit is used, which ensures that the car stops with sufficient efficiency.

The brake pedal is of the suspended type.

A brake light switch is installed in the bracket of the pedal assembly above the brake pedal - its contacts close when the pedal is pressed.

A vacuum booster is used to reduce the force on the brake pedal, using the vacuum in the receiver of the running engine.

The vacuum booster is located in the engine compartment between the pedal pusher and the brake master cylinder and is attached with four nuts (through the front shield) to the pedal bracket.

The vacuum booster is non-separable, if it fails, it is replaced.

The master brake cylinder is secured with nuts to two studs of the vacuum booster housing.

A hydraulic brake fluid reservoir is installed on top of the cylinder, which contains a reserve of working fluid.

The reservoir body has marks for the maximum and minimum fluid levels, and a sensor is installed in the upper part, which turns on the indicator in the instrument cluster when the fluid level drops below the MIN mark.

When the brake pedal is pressed, the pistons of the master cylinder move, creating pressure in the hydraulic drive, which is supplied through pipes and hoses to the working cylinders wheel brake mechanisms.

The front wheel brake mechanism is a disc brake with a floating caliper, which includes a support made together with a single-piston wheel cylinder.

The brake shoe guide is attached to the steering knuckle with two bolts, and the caliper is attached with two bolts to the guide pins installed in the holes of the shoe guide.

Protective rubber covers are installed on the pins.

Plastic grease is placed in the holes for the pins of the shoe guide.

When braking, the fluid pressure in the hydraulic drive of the brake mechanism increases and the piston, moving out of the wheel cylinder, presses the inner brake shoe to the disc.

Then the caliper (due to the movement of the guide pins in the holes of the shoe guide) moves relative to the disc, pressing it outer brake shoe.

A piston with a rectangular rubber sealing ring is installed in the cylinder body.

Due to the elasticity of this ring, a constant optimal gap is maintained between the disc and the brake pads.

Rear wheel brake mechanism with the drum removed on a 4x2 vehicle: 1 - brake shield; 2 - rear brake shoe with parking brake drive lever; 3 - pressure spring shoe; 4 - spring cup; 5 - support post; 6 - upper tension spring; 7 - wheel cylinder; 8 - spacer bar with clearance adjuster; 9 - adjuster spring; 10 - front shoe; 11 - parking brake cable; 12 - lower tension spring

The rear wheel brake mechanism is a drum, with a two-piston wheel cylinder and two brake shoes, with automatic adjustment of the gap between the shoes and the drum.

The brake drum is also the rear wheel hub and has a pressed-in bearing.

Elements of the automatic adjustment mechanism for the gap between the shoes and the drum of a 4x4 vehicle: 1 - a threaded tip coil spring; 2 - threaded end of the spacer bar; 3 - spring lever of the regulator; 4 - spacer bar; 5 - coil spring of the spacer bar; 6 - leaf spring; 7 - ratchet nut

The mechanism for automatic adjustment of the gap between the pads and the drum consists of a composite spacer bar of the pads, a regulator lever and its spring.

It starts working when the gap between the pads and the brake drum increases.

When the brake pedal is pressed, under the action of the pistons of the wheel cylinder, the pads begin to diverge and press against the drum, while the projection of the regulator lever moves along the cavity between the teeth of the ratchet nut.

When the pads are worn to a certain extent and the brake pedal is pressed, the regulator lever has enough travel to turn the ratchet nut by one tooth, thereby increasing the length of the spacer bar and simultaneously reducing the gap between the pads and the drum.

Thus, the gradual lengthening of the spacer bar automatically maintains the gap between brake drum and shoes. The wheel cylinders of the rear brake mechanisms are identical.

The front brake shoes of the rear wheels are identical, but the rear ones are different - they have mirror-symmetrical non-removable parking brake levers.

The spacer bar and ratchet nut of the brake mechanisms of the left and right wheels are different.

The ratchet nut and the end of the spacer bar of the left wheel have a left-hand thread, and the ratchet nut and the end of the spacer bar of the right wheel have a right-hand thread.

The brake adjuster levers of the left and right wheels are mirror-symmetrical.

The car is equipped with an anti-lock braking system (ABS), which provides more effective braking by reducing the fluid pressure in the brake mechanisms of the wheels at the moment of their locking.

The fluid from the main brake cylinder enters the ABS unit, and from there it is supplied to the brake mechanisms of all wheels.

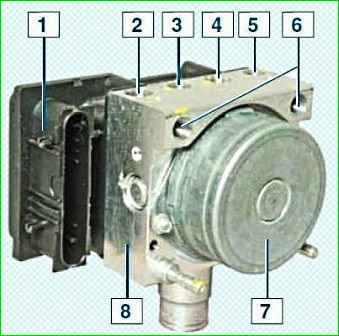

ABS unit: 1 - control unit; 2 - hole for connecting the brake mechanism pipe of the front right wheel; 3 - hole for connecting the brake mechanism pipe of the rear left wheel; 4 - hole for connecting the brake mechanism pipe of the rear right wheel; 5 - hole for connecting the brake mechanism pipe of the front left wheel; 6 - hole for connecting the pipe of the master brake cylinder; 7 - pump; 8 - hydraulic unit

The ABS unit, mounted in the engine compartment on the right side member, near the front shield, consists of a hydraulic unit, a modulator, a pump and a control unit.

The ABS operates depending on the signals from the wheel speed sensors. The sensors are of the inductive type.

The front wheel speed sensor is located in the wheel hub assembly - inserted into the groove of a special sensor mounting ring, clamped between the end surface of the outer ring of the hub bearing and the flange of the hole in the steering knuckle for the bearing.

The setting disk of the front wheel speed sensor is the protective washer of the hub bearing, located on one of the two end surfaces bearing.

This dark-colored washer is made of magnetic material. On the other end surface of the bearing is a regular light-colored protective washer made of thin sheet metal.

When the car brakes, the ABS control unit detects the start of wheel locking and opens the corresponding electromagnetic valve of the modulator to release the working pressure fluid in the channel.

The valve opens and closes several times per second, so you can make sure that the ABS is working by the slight tremor of the brake pedal when braking.

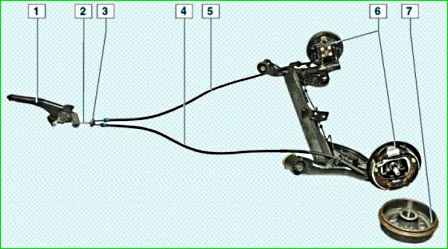

The parking brake drive is manual, mechanical, cable, on the rear wheels.

It consists of a lever, a front cable with an adjusting nut on its tip, an equalizer, two rear cables and levers in the brake mechanisms of the rear wheels.

The parking brake lever, fixed between the front seats on the floor tunnel, is connected to the front cable.

An equalizer is attached to the rear tip of the front cable, into the holes of which the front tips of the rear cables are inserted.

The rear tips of the cables are connected to the levers of the parking brake drive, fixed to the rear shoes.

During operation (until the pads of the rear brake mechanisms are completely worn out), adjustment of the parking brake drive is not required, because the extension of the brake mechanism spacer bar compensates for wear of the pads.

The parking brake drive must be adjusted only if the cables or parking brake lever are replaced.

Possible brake system malfunctions and methods of correction

Cause of malfunction - Method of elimination

Increased working stroke of the brake pedal

Brake fluid leaking from the working brake cylinders - Replace the failed working brake cylinders, flush and dry the pads, discs and drums

Air in the brake system - Remove air by bleeding the system.

Damaged rubber sealing rings in the master brake cylinder - Replace the master cylinder

Damaged rubber hoses of the brake hydraulic drive - Replace the hoses and bleed system.

Increased runout of the brake disc (more than 0.03 mm) - Grind or replace the disc if the thickness of the brake discs at the front of the wheels is less than 19.8 mm

Insufficient braking efficiency

Oiling of the brake pad linings - Wash and dry the pads

Jamming of the pistons in the working cylinders - Eliminate the causes of jamming, replace damaged parts

Complete wear of the brake pad linings - Replace the brake pads

Overheating of the brake mechanisms - Stop immediately and let the brake mechanisms cool down

Use of low-quality pads - Use original pads or products of companies specializing in the production of brake system parts

Breach of the tightness of one of the circuits (accompanied by a failure brake pedal) - Replace damaged parts, bleed the system

Brake pedal position is out of alignment - Determine the cause of the increase in full travel and replace damaged parts

Brake booster rod protrusion adjustment is out of adjustment - Contact a service center to adjust the booster

Anti-lock braking system (ABS) malfunction - Contact a service center to check the anti-lock braking system

Incomplete release of all wheels

No free travel of the brake pedal - Replace the master brake cylinder

Brake booster rod protrusion is increased - Contact a service center to adjust the booster

Swelling of the rubber seals of the master cylinder due to gasoline, mineral oils, etc. getting into the fluid. - Flush and bleed the entire hydraulic drive system, replace rubber parts

Jamming of the master cylinder pistons - Check and replace the master cylinder if necessary

Brakes one wheel with the pedal released

Broken or weakened tension springs of the parking brake shoes - Replace the spring

Jamming of the piston in the working cylinder due to contamination or corrosion of the housing - Replace the working cylinder and bleed the brake hydraulic drive system

Swelling of the sealing rings of the working cylinder due to foreign impurities getting into the fluid - Replace the working cylinder and bleed the brake hydraulic drive

Violation of the position of the caliper relative to the brake disc when the mounting bolts are loosened - Tighten the mounting bolts, replace damaged parts if necessary

Incorrect adjustment of the parking brake system - Adjust the parking brake system

Malfunction of the anti-lock braking system - Contact the service to check the anti-lock braking system

Skidding or pulling the car to the side when braking

Jamming of the piston of the working cylinder - Check and fixte piston sticking in the cylinder

Any tube is clogged due to a dent or blockage - Replace or clean the tube

Discs, drums and brake shoe linings are dirty or oily - Clean the brake parts

Wheel alignment is incorrect - Adjust the wheel alignment

Uneven tire pressure - Set the required tire pressure

One of the brake system circuits is not working (accompanied by a decrease in braking efficiency) - Replace the damaged parts and bleed the system.

If this does not lead to the desired result, contact the service to check the anti-lock braking system (if installed on the car)

Increased force on the brake pedal when braking

Vacuum booster is faulty - Replace booster

The hose connecting the vacuum booster and the engine intake pipe is damaged or loose - Replace the hose

Swelling of the rubber cylinder seals due to gasoline, mineral oils, etc. getting into the fluid - Replace the cylinders, flush and bleed the system

Squeaking or vibration of the brakes

Oily fouling of the friction linings - Clean the linings with a wire brush using warm water and detergents. Eliminate the causes of fluid or grease getting on the brake pads

Worn pads or foreign inclusions in them - Replace the pads

Excessive runout or uneven wear (felt by vibration of the brake pedal) of the brake disc - Grind or replace the disc if the thickness of the front brake discs is less than 19.8 mm