Install the gearbox on a special stand or workbench with the rear cover facing up

Using a 13 mm head, unscrew the three bolts securing the rear cover (Fig. 1).

Remove the cover. The cover must be removed carefully along the horizontal axis of the box, since the cover has a lubrication tube that enters the hole in the primary shaft.

Using a 27 mm head, unscrew the nut securing the fifth and reverse gear block gear (Fig. 2)

Use pliers to remove the lock washer (Fig. 3)

Using a punch (you can use an old valve) and a hammer, knock out the fifth gear fork mounting pin (Fig. 4)

Using a puller, remove the fifth gear pinion together with the fork.

If you don't have a puller, you can use two powerful screwdrivers (Fig. 5)

Remove the plug (Fig. 6)

Remove the spacer washer (Fig. 7) (when removing the washer, you need to remember its position so as not to mix it up during assembly,

- the eighth figure shows the correct position of the washer)

Using the internal torxE-16 head, unscrew the bolt of the rear end of the secondary shaft (Fig. 9)

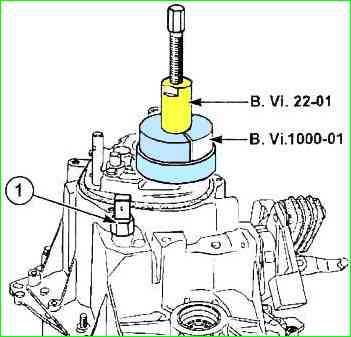

We remove the fifth gear driven gear using a three-finger puller or using B.Vi tools. 22.01 and B.Vi.1000-01 (see Fig. 10).

If there is no puller, you can use two powerful slotted screwdrivers, having first screwed the bolt onto the rear end of the secondary shaft.

The assistant rests the screwdrivers against the end of the gear, and presses the gear off with gentle blows on the bolt (Fig. 11).

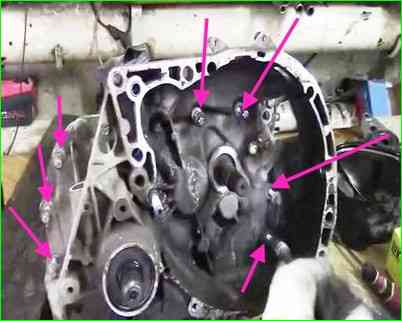

Using a TorxE-12 head (in some cases, a TorxE-14), unscrew the 16 bolts securing the gearbox housing to the clutch housing (Fig. 12).

Five bolts are located inside the clutch housing.

Before disconnecting the crankcases, you need to attach a magnet to the fork rod so as not to lose the balls and springs of the locks (Fig. 13)

We insert a thin slotted screwdriver between the thickened lugs of the crankcases, and use a hammer to disconnect the gearbox crankcases (Fig. 14).

The crankcases are sealed with glue sealanta.

After disconnecting the crankcases, remove the three springs and three retainer balls.

View of the spring and ball in Figure 15.

Remove the magnet installed in the gearbox (Fig. 16).

You can see the wear chips of the gearbox parts on the magnet.

Knock out the pin of the III and IV gears (Fig. 17)

And we extract the rod together with the fork (Fig. 18)

Remove the retainer balls from the technological holes shown in Figure 19.

After this, we take out the secondary shaft (Fig. 20)

With a punch, knock out the pin from the reverse gear fork (Fig. 21)

Remove the primary shaft and reverse clutch (Fig. 22)

After that, wash all the parts and inspect the bearings. If there are signs of wear, replace the parts.

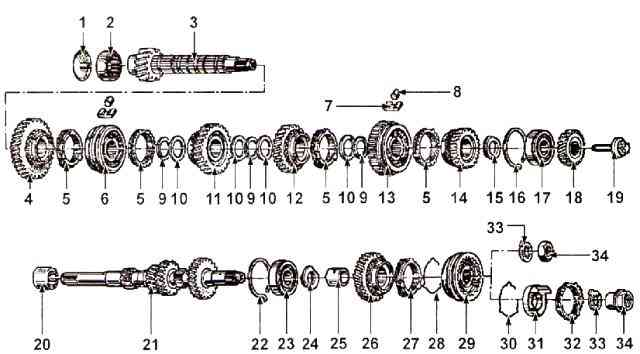

The gearbox shaft parts are shown in Figure 23

JH3 gearbox parts: 1 - oil deflector; 2,17, 23 - bearings; 3 - secondary shaft; 4 - 1st gear pinion; 5 - synchronizer locking ring; 6 - 1st and 2nd gear synchronizer hub; 7, 28, 30 - springs; 8 - cracker; 9,16, 22 - retaining rings; 10 - splined washer; 11 - 2nd gear pinion; 12 - 3rd gear pinion; 13 - 3rd and 4th gear synchronizer hub; 14 - 4th gear pinion; 15 - thrust washer; 18 - 5th gear pinion; 19 - secondary shaft rear end bolt (70 Nm); 20 - front bearing; 21 - primary shaft; 24 - thrust washer; 25 - gear sleeve; 26 - 5th gear pinion; 27 - synchronizer locking ring; 29 - synchronizer hub; 31 - friction cone; 32 - synchronizer locking ring; 33 - washer; 34 - primary shaft rear end nut (190 Nm).

Prepare all parts for gearbox assembly. Gearbox assembly will be discussed in the next article.