Installing pistons with connecting rods

Lubricate the upper parts of the cylinders and the connecting rod journals of the crankshaft with engine oil.

Install the pistons in assembly with connecting rods using a ring for installing pistons with piston rings in the cylinder liner, observing the correspondence of pistons and cylinders.

The marks on the pistons should be directed towards the flywheel.

Install the connecting rods on the connecting rod journals of the crankshaft.

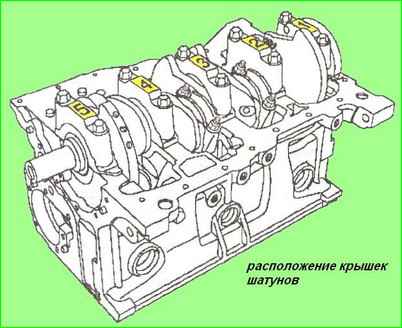

Install the connecting rod caps (see Fig. 13).

Tighten the connecting rod cap stud nuts to a torque of 20 Nm + (45˚±5˚).

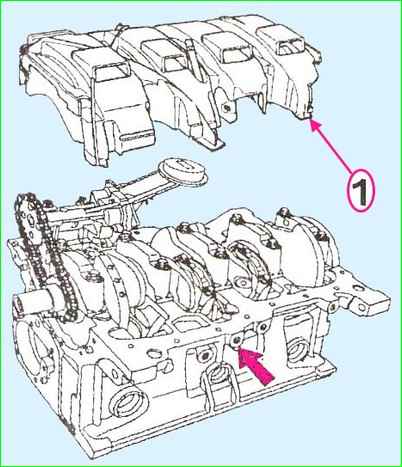

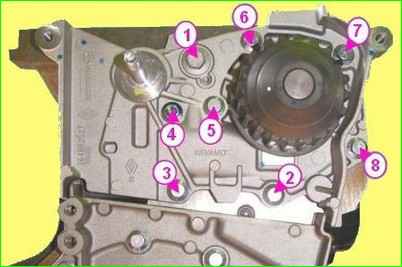

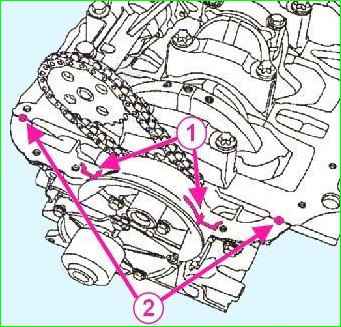

Install the oil pump drive sprocket, oil pump drive chain and oil pump (see Fig. 14).

Tighten the oil pump mounting bolts to the specified torque.

The tightness of the front cover of the engine block can be ensured either by installing a gasket or installing the cover on Loctite 518 sealant.

The seating surfaces of the cylinder block and the front cover of the engine block must be clean, dry and free of oil, do not touch them with your hands.

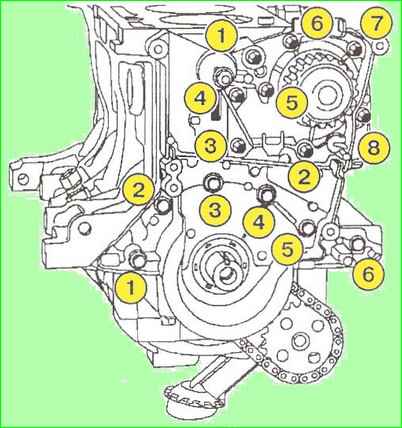

Loctite518 is applied in a 1 mm wide strip, the location of the application is shown in Fig. 15.

Install the front cover of the engine block.

Tighten the bolts securing the front cover of the cylinder block in the order shown in Fig. 16.

The seating surfaces of the cylinder block and water pump must be clean, dry and free of oil, do not touch them with your hands.

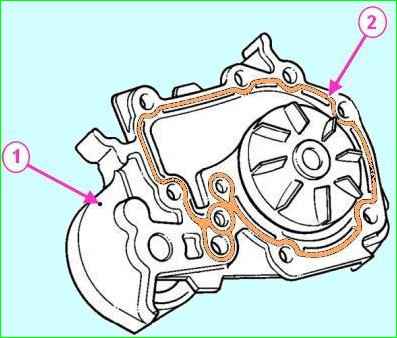

Install the water pump. Instead of a gasket, use Loctite 518 sealant (1 mm wide strip), the place of application of the composition is shown in Fig. 17.

Note. Apply one or two drops of Loctite-Frenetanch to the bolts of the water pump (1) and (4) (see Fig. 18).

Tighten the M6 bolts and the M8 bolt in the order shown in Fig. 18.

Apply four stripes of Rhodorseal 5661, approximately 5 mm wide, to the joints of the front and rear covers and to the seating surfaces of the cylinder block.

See 1, Fig. 19 for the location of the application points. for the rear cover, the application of the compound is similar.

Apply two drops of Rhodorseal 5661 with a diameter of about 7 mm to the seating surface of the front cover and cylinder block (2).

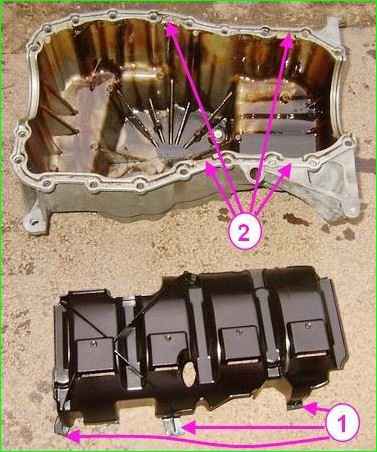

When installing the engine oil pan, make sure that the tongues (1) of the oil separator are installed in the grooves (2) (see Fig. 20).

The cylinder block and the engine oil pan must be aligned on the flywheel side to avoid damaging the clutch housing when connecting the engine to the gearbox.

Install the oil separator.

Install the oil pan with a new gasket.

Tighten the oil pan mounting bolts in the order shown in Fig. 21:

- - First pass, Nm 8;

- - Second pass, Nm 14.

Install the oil level sensor and tighten it to the required torque.

Install the knock sensor and tighten it to the required torque.

Install the oil pressure sensor and tighten it to the required torque.

See the tightening torques at the beginning of the article, see the article - "How to assemble a cylinder block"

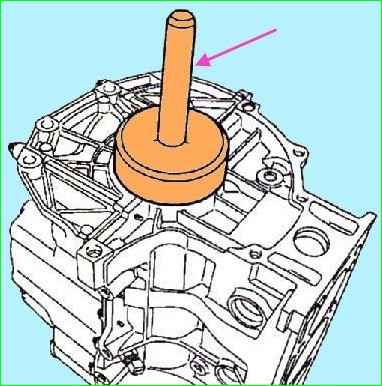

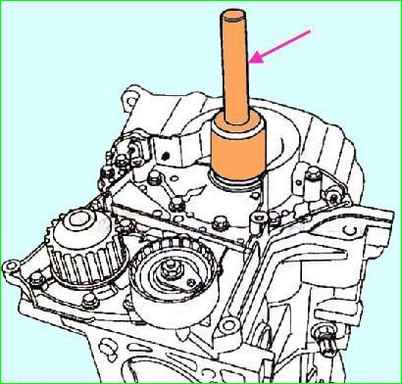

Press in the rear crankshaft oil seal using the Mot.1129-01 tool (see Fig. 22).

Press in the front crankshaft oil seal using the Mot.1385 tool (see Fig. 23).

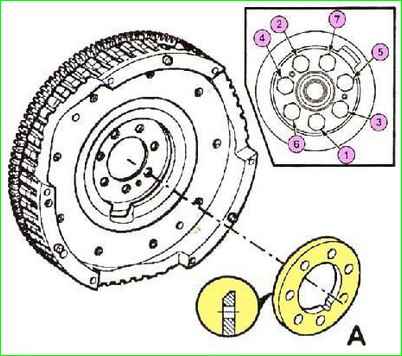

Replace the flywheel mounting bolts. Reusing old bolts is not allowed.

Clean the crankshaft mounting flange and threaded holes for the mounting bolts.

Check the technical condition of the flywheel.

Degrease the flywheel support surface and the counter surface on the crankshaft flange.

Install the spacer sleeve (A, Fig. 24), mounting position - chamfer to flywheel.

Coat the threaded surfaces of the bolt threads with Loctite Frenetanch.

Tighten the mounting bolts by hand until they touch the flywheel, then lock the flywheel with the Mot582-01 or Mot1677 locking agent (see Fig. 25).

Tighten the flywheel mounting bolts to 55 Nm.

Install the clutch slave disk and clutch housing with pressure plate assembly.

Center the slave disk using the Emb1518 mandrel (see Fig. 26), the mandrel is suitable for centering VAZ vehicle disks.

Tighten the clutch housing mounting bolts.

Remove the flywheel retainer.