Engine removal was discussed in the article - "Removing the K7M engine"

Place the trolley with the engine and gearbox assembly under the car, which is raised on a lift.

Lower the car to the engine level and install the engine mount stops.

Install according to the marks on the body made during removal:

- - right engine mount support;

- - left engine mount support.

Install:

- - front suspension subframe;

- - use an 18 mm head to tighten the two bolts securing the steering gear to the front suspension subframe.

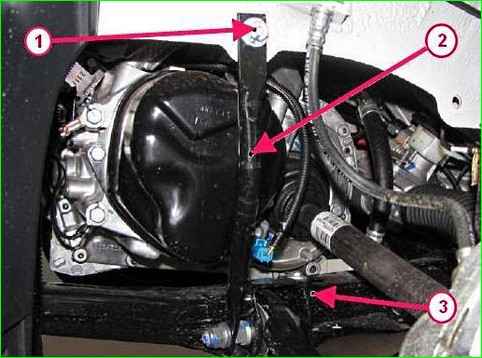

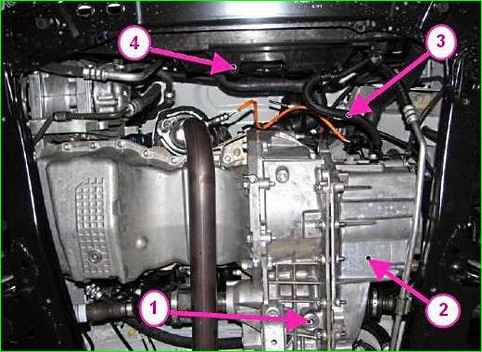

Using a 13 mm socket, tighten bolts 1 (Fig. 1) for the upper mount of the front suspension subframe braces.

Install the front wheel drives.

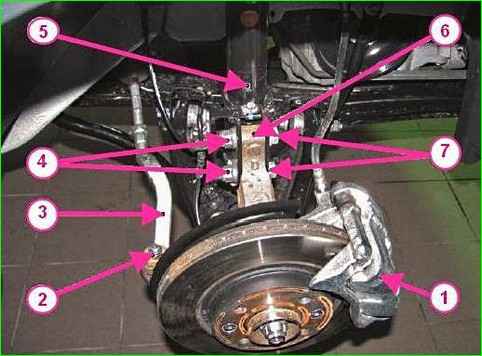

Using a 18 mm head, tighten bolts 7, securing shock absorber struts 5 to steering knuckles 6 (Fig. 2).

- - with a 16 mm head, ball joints of outer ends 3 of steering rods;

- - with a 18 mm head, front brakes;

Tightening torques:

- - steering gear mounting bolts to front suspension subframe 105 Nm (10.5 kgf.m) (replaceable head 18);

- - upper bolts securing front suspension subframe struts 21 Nm (2.1 kgf.m) (replaceable head 13);

- - mounting bolts shock absorber strut to steering knuckle 105 Nm (10.5 kgf.m) (replaceable head 18);

- - nuts for fastening ball joint pins of steering rod ends 37 Nm (3.7 kgf.m) (replaceable head 16);

- - front brake fastening bolts 105 Nm (10.5 kgf.m) (replaceable head 18).

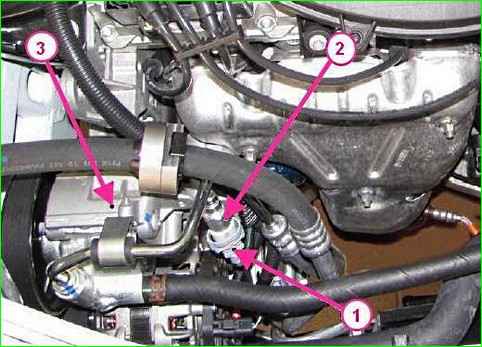

Install the ground wires on the gearbox (replaceable head 13, extension, ratchet).

Tightening torque of bolts 1, figure 2-17, fastening wires 2 "ground" on the gearbox 21 Nm (2.1 kgf.m) (replaceable head 13, extension, key torque).

Install the exhaust system.

Install the rear engine mount, article - "How to replace engine mounts"

For cars with a JH3 gearbox

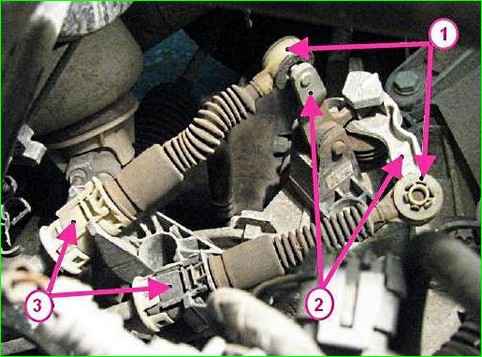

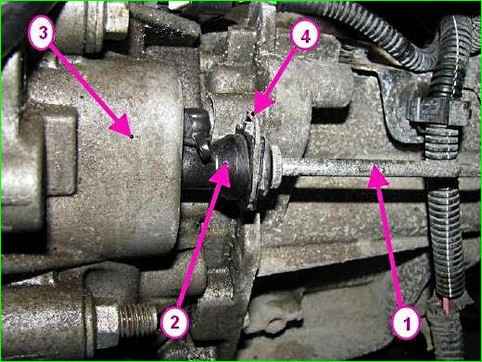

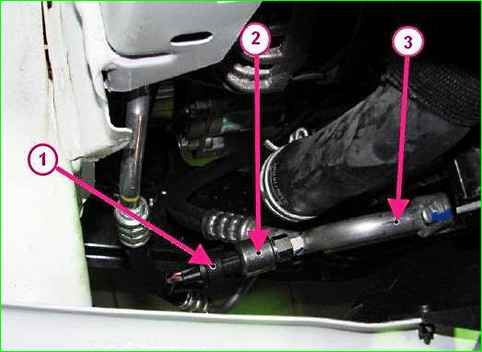

Apply MOLYKOTE 33 grease to bolt 2, fastening the gearbox control rod.

Attach rod 3 of the gearbox control rod to the gearbox.

Tightening torque of the bolt fastening the gearbox control rod to the gearbox 27.5 Nm (2.75 kgf.m) (replaceable head 10, extension, torque wrench).

Install protective cover 1 on the gearshift lever.

Install the clutch cable

For vehicles with a JR5 gearbox

Install stoppers 3, gear selection and shift cable sheaths on the gearbox bracket.

Attach joints 1 of the gear selection and shift cables to the levers on the gearbox.

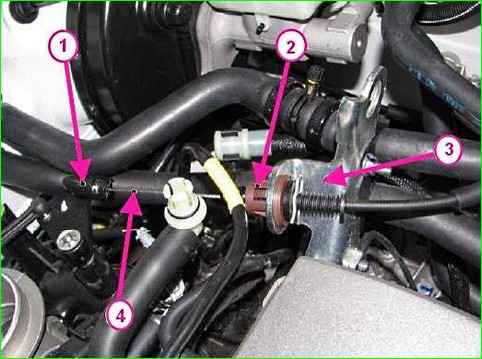

Remove plugs from the openings in the pipeline and the clutch hydraulic drive slave cylinder.

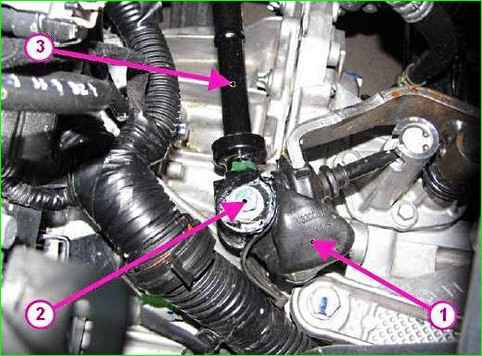

Connect the pipeline 1, clutch hydraulic drive to the slave cylinder 2, by pressing the lock 4 (Fig. 5).

Bleed air from the clutch hydraulic drive circuit.

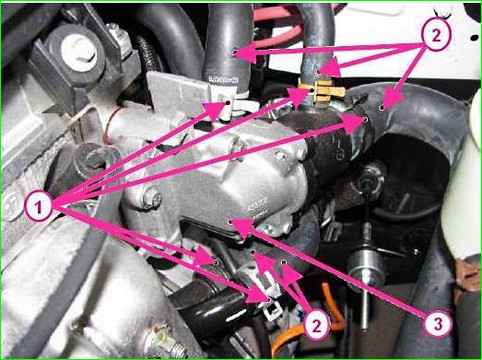

Install the power steering reservoir.

Install and connect the high- and low-pressure lines of the power steering.

Connect connector 2 of the wiring harness to the pressure sensor in the power steering system (Fig. 6).

Install the cooling system hoses in the holder.

Connect hoses 2 (Fig. 7), engine cooling system with new clamps:

- - to thermostat housing 3;

- - to coolant supply pipe;

- - to engine cooling system radiator.

Connect:

- - brake booster vacuum hose to intake manifold;

- - crankcase ventilation hose to intake manifold;

Connect:

- - fuel supply line 1, to the fuel rail 2 (Fig. 8);

- - wiring harness block to the electromagnetic valve of the adsorber purge;

Attach:

- - retainer 2, throttle drive cable sheath (Fig. 9);

- - ball end 1 of the drive cable to the throttle valve unit;

Connect:

- - connectors of the wiring harness 3, to the electric fan 4 of the engine cooling system (Fig. 10);

- - wiring harness to the fan of the cooling system.

Replace the sealing gasket of the plug 1 of the drain hole and install the plug with a new gasket. Tightening torque of the drain hole plug 22 Nm (2.2 kgf.m) (wrench for an internal square of 8 mm, replaceable nozzle for an internal square of 8 mm, torque wrench).

Unscrew the plug of the filler hole.

Fill the gearbox with oil. The oil level should reach the lower edge of the filler hole (filling unit S-223-1, transmission oil according to the current "Codifier of the main and auxiliary materials used in maintenance and repair of LADA cars" K 3100.25100.00018-2008, filling rate: for JH3 - 2.8 l; for JR5 - 2.5 l).

Install the filler plug.

Pour fluid into the cooling system.

For vehicles with an air conditioning system, additionally connect connector 1, wiring harness to refrigerant pressure sensor 2 (Fig. 11)

Remove the process plugs and connect the pipeline to the air conditioning compressor.

Install the hub fastening nuts using the device. Tightening torque of the hub fastening nut 280 Nm (28.0 kgf.m) (device Rou. 604-01, replaceable head 32, ratchet, torque wrenchny).

Install:

- - side mudguards and pads;

- - engine sump guard;

- - front wheels;

- - injection system ECU.

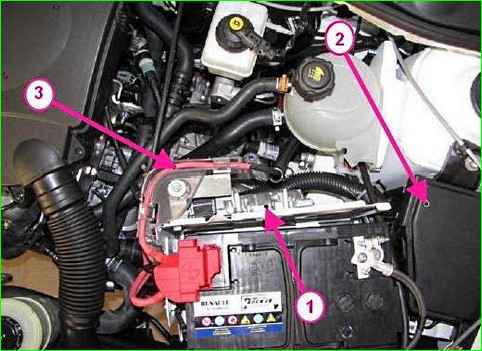

Install:

- - fuse holders and relay blocks in block 1, relays and fuses;

- - fuse and relay box cover.

Install the 3 engine wiring harness into the mount on the shelf under the battery.

Install housing 3, air filter, air intake pipe 1, battery pan, battery

Additionally for vehicles with power steering:

Fill the power steering system with working fluid (Mobil ATF 52475 power steering oil).

Bleed air from the power steering system by turning the steering wheel from the extreme left position to the extreme right.

Start the engine and bleed air from the power steering system by turning the steering wheel from the extreme left position to the extreme right.

Add the working fluid level in the power steering pump reservoir to normal.

Make sure there are no working fluid leaks.

Bleed air from the cooling system engine

For vehicles with air conditioning - fill the refrigerant into the air conditioning system circuit.