The clutch of the Lada Largus car is single-plate, dry type

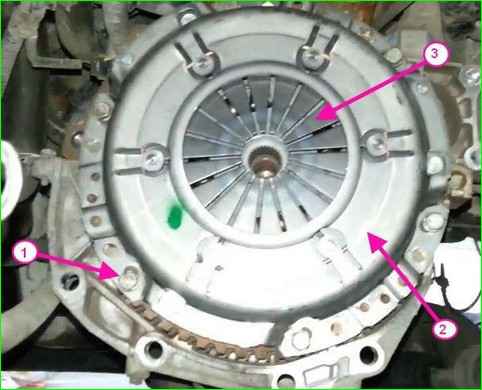

A pressure plate with a central diaphragm spring and a driven plate with friction linings attached with rivets are installed.

The pressure plate is mounted in a stamped steel casing and is attached to the flywheel with six bolts (Figure 1).

This car with a manual transmission has the same clutch. Only the drive differs depending on the gearbox model.

On a car with a JH3 gearbox, the clutch is controlled by a cable, and on a car with a JR5 gearbox, it is controlled by a hydraulic drive.

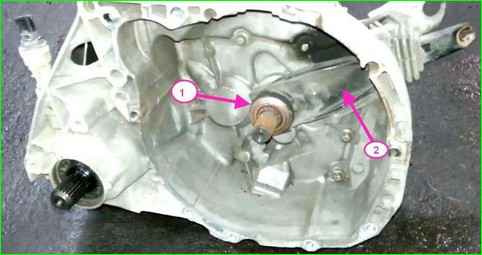

And on a car with a JH3 gearbox, the release bearing moves along the guide sleeve using a fork, and on a car with a JR5 gearbox, a hydraulic slave cylinder is installed directly on the gearbox clutch.

The driven disc (Fig. 2) is installed on splines of the primary shaft of the gearbox and is clamped by a diaphragm spring.

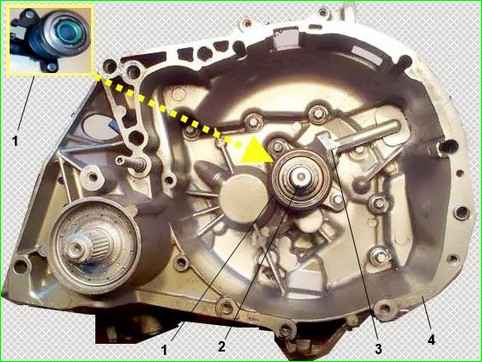

Release bearing 1 (Fig. 3), in the JH3 gearbox is controlled by fork 2.

The release bearing is of a sealed type and does not require lubrication during operation.

The fork is inserted into the grooves of the release bearing sleeve.

A rubber boot is installed on the fork shoulder.

The fork is controlled by a cable, one end of which is inserted into the fork and the other end is attached to the clutch pedal.

The release bearing in the JR5 gearbox is combined with a slave cylinder attached with two bolts to the clutch housing.

The release bearing in the JR5 gearbox in Figure 4.

The hydraulic clutch release drive with the JR5 gearbox consists of a master cylinder, which is installed in the engine compartment, and a slave cylinder.

The hydraulic drive is connected using a tube and a hose. The master cylinder is connected to a reservoir, which is common for the brake system and clutch.

Possible malfunctions of the Lada Largus clutch and how to fix it

Incomplete disengagement of the clutch (clutch drags)

Insufficient full travel of the clutch pedal - Adjust the initial setting of the clutch drive cable

Warping of the driven disk (end runout more than 0.5 mm) - Straighten or replace the disk

Jamming of the driven disk hub on the splines of the input shaft - Clean the splines, wash with solvent.

If the splines are worn, replace the input shaft or driven disk

Skewing or warping of the pressure plate - Replace the pressure plate assembly

Loose rivets or breakage of friction linings driven disk - Replace the linings or driven disk, check the axial runout of the disk

Failure of the clutch drive cable or the mechanism for compensating for wear of the driven disk linings - Replace the cable

Air entering the hydraulic drive system of a car with a JR5 gearbox - Bleed the clutch hydraulic drive

Fluid leaking from the master or slave cylinder - Replace the faulty cylinder

Incomplete clutch engagement (clutch slips)

Increased wear or burning of the friction linings of the driven disk

Oiling of the friction linings of the driven disk, flywheel surfaces and pressure plate - Replace the friction linings or the driven disk assembly

Wash the oily surfaces with white spirit, replace the worn ones or damaged gearbox and engine seals.

Check for oil leaks through the flywheel mounting bolts; if there is a leak, install the bolts with sealant

Damaged or jammed clutch drive ia - Eliminate the causes of seizure. Replace damaged parts

Jerking during clutch operation

Oiling of the friction linings of the driven disk, flywheel surfaces and pressure plate - Thoroughly wash the oiled surfaces with white spirit, replace worn or damaged gearbox and engine oil seals.

Check for oil leaks through the flywheel mounting bolts, if there is a leak, install the bolts with sealant

Seizure in the clutch drive - eliminate the causes of seizure. Replace damaged parts

Damaged or warped pressure plate surface - Replace pressure plate assembly

Increased noise when engaging clutch

Failed damper springs of driven disk - Replace driven disk assembly

Increased noise when disengaging clutch

Worn, damaged, grease leaking from clutch release bearing - Replace bearing