Failure of the timing belt (breakage or shear of the teeth) will lead to the valves hitting the pistons due to the misalignment of the rotation angles of the crankshaft and camshaft and, as a result, to expensive engine repairs

Therefore, in accordance with the vehicle maintenance regulations, we replace the belt every 120 thousand km or after 6 years (whichever comes first), regardless of its condition.

We recommend checking the condition of the belt at each maintenance.

The surface of the toothed part of the belt should not have folds, cracks, undercuts of the teeth and delamination of the fabric from the rubber.

The reverse side of the belt should not have wear that exposes the cord threads and signs of burning.

There should be no delamination on the end surfaces of the belt. The belt must be replaced if traces of oil are found on it.

To assess the condition and replace the timing belt, remove the right support of the power unit and the right mudguard of the engine compartment.

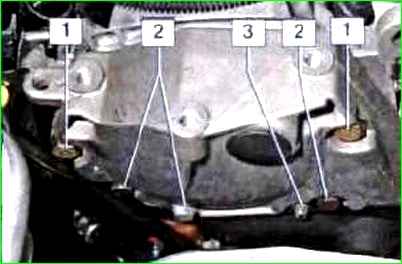

Unscrew the six bolts securing the upper drive cover with a 16 head

— two bolts 1, with a 13 head — three bolts 2 and with an 8 head — bolt 3.

Remove the upper timing belt cover

Use an 18 mm head to turn the crankshaft clockwise and visually inspect the condition of the belt.

You can determine the belt tension without a device.

If you can twist the leading branch of the belt (at the point located between the toothed pulleys of the camshaft and the coolant pump) more than 60°—70° with the force of your thumb and forefinger, then the belt is weak and needs to be tightened.

To adjust the belt tension, remove the lower cover.

Using an 8 mm head with a ratchet, unscrew the two bolts securing the lower timing belt cover.

Remove the lower cover timing belt.

After loosening the tension roller mounting nut with a 16 spanner, turn the roller counterclockwise with a special spanner (the timing belt tensioner for front-wheel drive VAZ cars is suitable), tensioning the belt.

In this position of the roller, tighten the nut that secures it.

After turning the crankshaft clockwise by the bolt securing its pulley by two turns, we check the belt tension again and repeat the adjustment if necessary.

We install the removed parts in the reverse order.

To replace the timing belt, we remove the accessory drive belt, the upper and lower timing belt covers. Article on replacing the accessory drive belt - "How to replace the alternator belt"

When unscrewing the crankshaft pulley mounting bolt, it is necessary to block the shaft from turning.

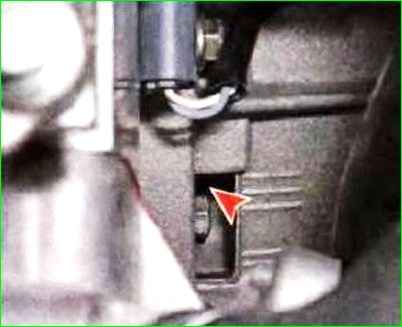

To do this, you can use the window in the clutch housing, located above under the thermostat housing.

While turning the crankshaft (you will need an assistant), watch the clutch housing movement in the window.

We achieve that one of the six bolts fastening the housing to the flywheel appears in the window.

We stop the crankshaft from turning by inserting the blade of a power slotted screwdriver between the upper wall of the window in the clutch housing and the head of the bolt fastening the housing.

With an "18" head, unscrew the bolt crankshaft pulley mounts and remove the screwdriver from the clutch housing window.

Removing the crankshaft pulley

If you have difficulty removing the pulley, pry it evenly from different sides with a mounting blade.

To turn the crankshaft further, you need to screw the pulley mounting bolt back into place.

To ensure that the bolt is completely screwed into the threaded hole in the crankshaft nose, install a spacer (bushing or set of washers).

Before removing the belt, in order not to disturb the valve timing, it is necessary to set the crankshaft and camshaft to the TDC (top dead center) position of the compression stroke of the 1st cylinder.

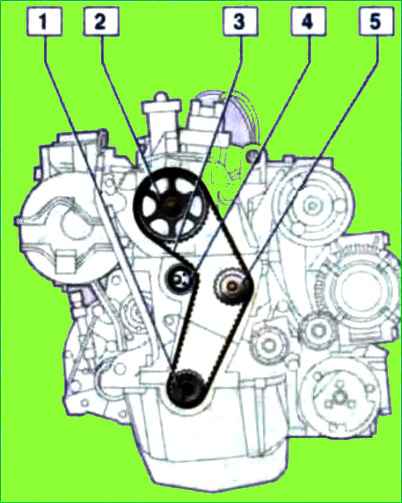

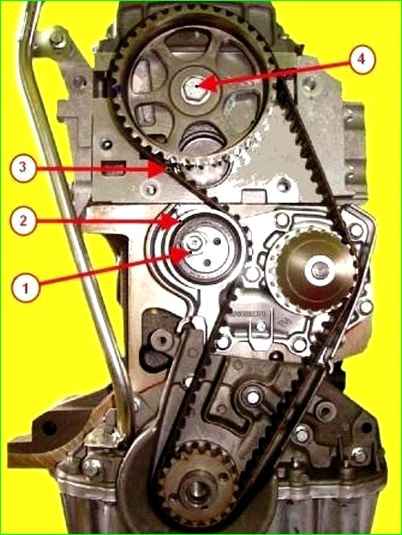

Turn the crankshaft by the bolt securing its pulley clockwise until mark 1 (a hole in the shape of a triangle) on the toothed pulley of the camshaft coincides with mark 2 (the Dacia logo), through which the imaginary vertical axis of the pulley on the cover passes. cylinder heads.

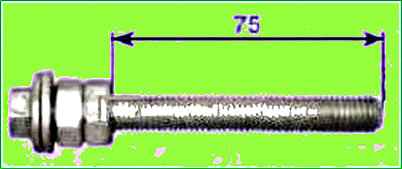

To check the crankshaft position at TDC for pistons of cylinders 1 and 4, the cylinder block has a hole with an M10 thread, into which a special installation pin with a threaded section length of 75 mm must be screwed.

When the crankshaft is at TDC for pistons of cylinders 1 and 4, the pin must rest against the milled area on the crankshaft cheek and block the shaft when trying to turn it clockwise.

Using a 14 mm socket, unscrew the plug from the threaded hole in the cylinder block, located on the block side, in the area of the 1st cylinder - under the oil pressure alarm sensor.

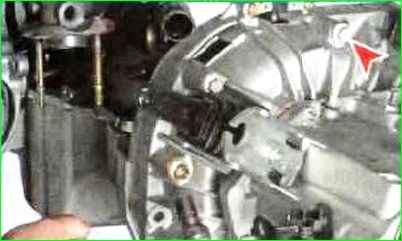

You can use the upper gearbox mount bolt to the cylinder block as an installation pin.

We screw two nuts onto the bolt and lock them so that the length of the threaded part is 75 mm.

We screw the manufactured device - the installation pin into the threaded hole of the block cylinders.

When the crankshaft is in the TDC position of the pistons of the 1st and 4th cylinders, the adjusting pin 1 will screw into the hole to the end of its thread and rest against the milled area 2 on the crankshaft cheek (shown for clarity on a dismantled engine and with the oil pan removed).

In this case, the crankshaft cannot be turned clockwise

If, when screwing in the adjusting pin, you you will feel that it has stopped, and the end of the nut on the finger will not touch the end of the boss of the hole in the cylinder block (there will be a gap between the nut and the boss), then turn the crankshaft a littleth shaft counterclockwise by the pulley mounting bolt.

Then screw the mounting pin into the block hole all the way (until the ends of the pin nut and the hole boss in the block touch) and turn the crankshaft clockwise until the cheek pad stops at the pin.

Having loosened the tension roller mounting nut, turn the roller clockwise, reducing the tension of the timing belt.

Remove the drive belt Timing belt.

After removing the belt, the shafts must not be rotated so as not to bend the valves.

To replace the tension roller, unscrew the nut that secures it and remove the tension roller.

Install the new tension roller and timing belt in the reverse order

When installing a belt with arrows on it, orient it so that the arrows match the direction of belt movement (clockwise)

After installing the belt on the crankshaft pulley, place the belt under the tension roller and put it on the camshaft and coolant pump pulleys fluids.

Tighten the timing belt as shown above.

Having unscrewed the installation pin from the hole in the cylinder block, turn the crankshaft two turns clockwise by the pulley mounting bolt until the mark on the camshaft pulley coincides with the mark on the cylinder head cover.

Then screw the installation pin into the hole in the cylinder block to check the correct installation of the crankshaft in the TDC position of pistons of the 1st and 4th cylinders and, if necessary, repeat the installation of the belt.

Unscrew the pin from the hole in the cylinder block and install the plug in place. The removed parts are installed in the reverse order.

Replace the auxiliary drive pulley mounting bolt with a new one and tighten it to the specified torque.

For reliable engine operation and to ensure the specified service life of the timing belt, it is better to check the belt tension using a strain gauge.

Tightening torques for fasteners when replacing the timing belt:

- - timing belt tension roller mounting nut – 50 Nm;

- - M10 timing belt upper cover mounting bolt – 44 Nm;

- - M8 timing belt upper cover mounting bolt – 22 Nm;

- - timing belt lower cover mounting bolt – 8 Nm;

- - auxiliary drive pulley mounting bolt – 30 Nm, tighten further by 80˚±5˚.