Cars not equipped with ABS have a rear brake pressure regulator

Removal

Install the car on a lift.

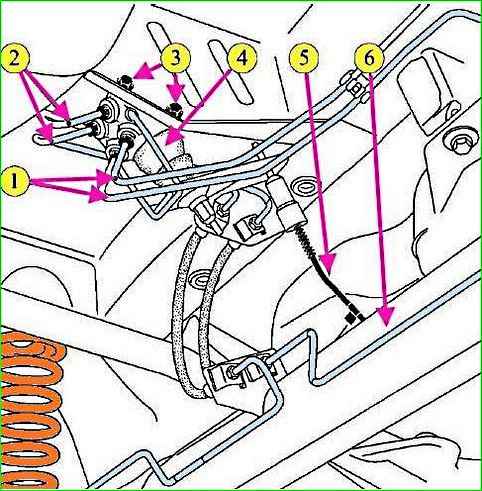

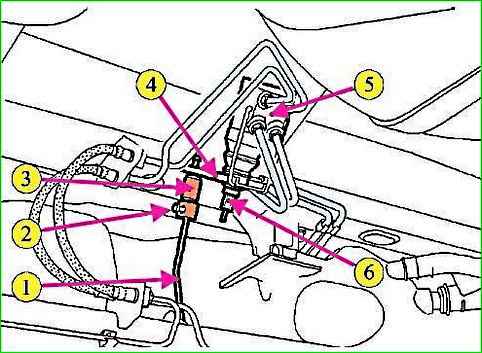

Using a brake pipe wrench, unscrew the brake pipe fittings 1 and 2, Figure 1, from the rear brake gearbox 4 and install plugs on the brake pipes and in the pressure regulator holes.

Disconnect the rod 5 of the rear brake pressure regulator drive from the beam 6 of the rear suspension arms.

Using a 10 mm socket, unscrew the bolts 3 of the pressure regulator and remove the regulator.

Installation

Install the rear brake pressure regulator in place and secure it with bolts. The tightening torque of the bolts is 12 Nm (1.2 kgf.m) (replaceable head 10, extension, torque wrench).

Remove the plugs from the holes of the regulator and brake pipes and screw the fittings of the brake pipes into the holes of the rear brake pressure regulator. Tightening torque of fittings 14 Nm (1.4 kgf.m).

Connect the rear brake pressure regulator drive rod to the rear suspension beam.

Bleed the brake system.

Adjusting the rear brake pressure regulator drive

When adjusting, the car must be in running order and standing on its wheels.

Adjust the rear brake pressure regulator, for which:

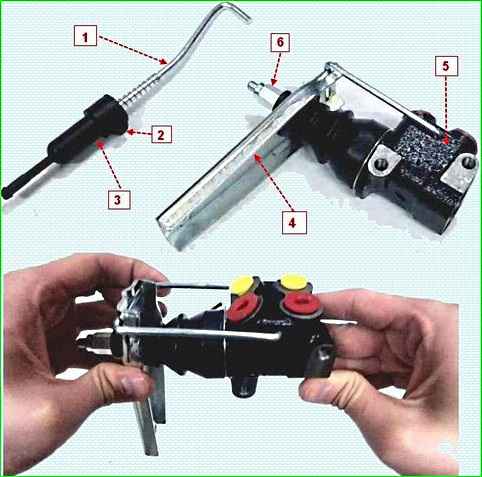

- - unscrew the tightening bolt 2, figure 2, of the adjusting coupling;

- - install the adjusting coupling 3 of the drive lever so that it touches the lever 4 of the rear brake pressure regulator;

- - tighten the tightening bolt. Bolt tightening torque 12 Nm (1.2 kgf.m) (replaceable head 10, torque wrench).

When adjusting, do not apply pressure to nut 6 of the regulator rod

Checking the rear brake pressure regulator

The rear brake pressure regulator is checked with the vehicle standing on its wheels, with one person on board and a full fuel tank.

The pressure is read diagonally by comparing the pressure in the rear brake mechanism with the specified pressure in the front brake mechanism.

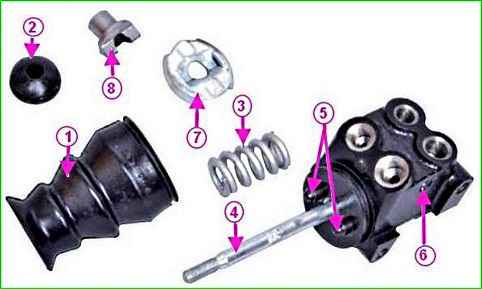

If the pressure value does not correspond to the norm on any of the rear brake mechanisms, replace the rear brake pressure regulator.

Be sure to check both brake circuits. Right front 7 left rear wheel and left front 7 right rear wheel.

Remove the protective caps, unscrew the brake bleed nipples from the right front and left rear brake mechanisms and connect pressure gauges to them.

Bleed the brake system through the bleed nipples on the pressure gauges.

Start the engine.

Press and hold the brake pedal in a position corresponding to the pressure in the front brake working cylinder of 100 bar.

Record the readings of the pressure gauge connected to the rear brake working cylinder.

Repeat the operation on other brake circuit.

If the pressure values exceed the permissible values specified in Tables 1 and 2, the rear brake pressure regulator must be replaced. Repair of the regulator is not provided.

The difference in pressure in the rear brake working cylinders must not exceed 4 bar, regardless of the load on the rear axle.

Control values of pressure in the rear wheel cylinders

Control values of pressure are given in Tables 1 and 2.

Without taking into account the distribution of load on the axles (the pressure check is performed with a full fuel tank)

Car model R90:

Pressure in the rear wheel cylinder, bar. Modification E0 and E1:

- - engine K7M - 37.50-48.40;

- - engine K4M - 29.50–40.40

Pressure in the rear wheel cylinder, bar. Modification E2:

- - K7M engine - 37.00 – 47.90;

- - K4M engine - 28.80 – 39.90

Taking into account the distribution of the load on the axles:

Car model F90:

Pressure in the rear wheel cylinder (with a load on the rear axle of 700 kg):

- - K7M engine - 50.68 – 61.88;

- - K4M engine - Not measured

Pressure in the rear wheel cylinder (with a load on the rear axle of 825 kg):

- - K7M engine - 64.20 – 75.40;

- - K4M engine - Not measured

Car model R90/5-seater:

Rear wheel cylinder pressure (with rear axle load of 700 kg):

- - K7M engine - 50.68 – 61.88;

- - K4M engine - 42.24 – 53.44

Rear wheel cylinder pressure (with rear axle load of 825 kg):

- - K7M engine - 64.20 – 75.40;

- - K4M engine - 57.20 – 68.30

Car model R90/7- local

Rear wheel cylinder pressure (with rear axle load of 700 kg):

- - K7M engine - 48.92 – 60.12;

- - K4M engine - 40.90 – 52.10

Rear wheel cylinder pressure (with rear axle load of 825 kg):

- - K7M engine - 59.90 – 71.10;

- - K4M engine - 52.40 – 63.60

Bleeding the brake system.

Checking the efficiency of the brake system.