Anti-lock braking system provides more efficient braking of the car by reducing the fluid pressure in the brakes at the moment of their locking

Fluid from the brake master cylinder enters the ABS unit, and from there it is supplied to the brake mechanisms

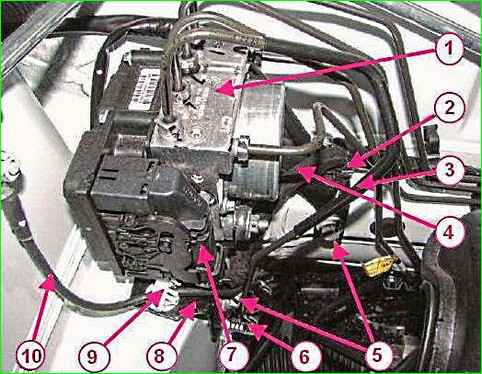

The hydraulic unit itself is mounted on the right side member, near the front shield, consists of a modulator, a pump and a control unit.

The unit operates depending on the readings of the wheel speed sensors.

When braking the car, the ABS unit determines the beginning of the wheel lock and opens the corresponding electromagnetic valve of the modulator to release the pressure of the working fluid in the channel.

The valve opens and closes several times per second to make sure that the ABS is working, you can tell by the slight tremor of the brake pedal at the moment of braking.

Removing the ABS unit

Installing car on a lift or inspection pit.

Disconnect the negative battery terminal.

Unscrew the three nuts securing the soundproofing to the front panel and right mudguard and move the soundproofing aside to gain access to the hydraulic unit (flat-head screwdriver).

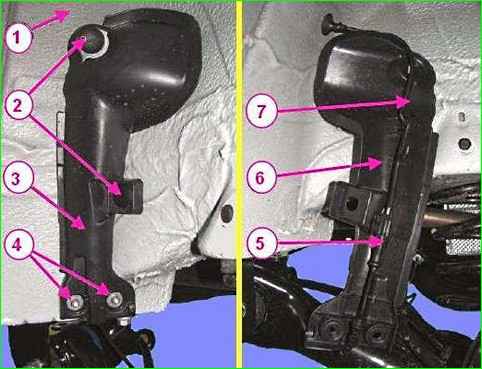

Disconnect the plug 7, Figure 1, of the front wiring harness from the hydraulic unit.

Disconnect the brake pipes from the hydraulic unit of the anti-lock braking system.

Install plugs in the holes of the hydraulic unit and on the brake pipes (key for brake pipes, technological plugs).

Remove the front wiring harness 4 from clamp 2, the ground wire 10 from clamp 9 and the brake pipe 3 from the clamp 6 for fastening to the hydraulic unit bracket (flat-head screwdriver).

Unscrew the bolts 5 for fastening the hydraulic unit bracket to the body and remove the hydraulic unit 1 assembled with the bracket 8 (replaceable head 13, Ratchet wrench).

Unscrew the bolts securing the hydraulic unit to the mounting bracket and remove the hydraulic unit (replaceable head 10, ratchet wrench).

Installation

Attention. When replacing the hydraulic unit, perform the ABS ECU parameter programming procedure.

To ensure the tightness of the hydraulic unit control unit connector, the hydraulic unit ground wire terminal must be oriented downwards.

Install the hydraulic unit on the mounting bracket and secure with bolts. The tightening torque of the bolts is 8 Nm (0.8 kgf.m) (replaceable head 10, ratchet wrench, torque wrench).

Install the hydraulic unit assembled with the bracket on the vehicle and secure with bolts. Tightening torque of bolts 22 Nm (2.2 kgf.m) (replaceable head 13, ratchet wrench, torque wrench).

Connect the plug-in block of the front wiring harness to the hydraulic unit connector.

Install the wiring harness, ground wire and brake pipe in the mounting brackets on the hydraulic unit bracket (flat-head screwdriver).

Remove the technological plugs from the openings of the hydraulic unit and brake pipes and connect the brake pipes to the hydraulic unit. Tightening torque of fittings 14 Nm (1.4 kgf.m) (brake pipe wrench, torque wrench).

Connect the ground wire terminal to the battery (10 spanner).

Bleed the brake system.

Removing and installing the front wheel speed sensor

Removal

Remove the front wheel. Raise the vehicle to a height convenient for performing work.

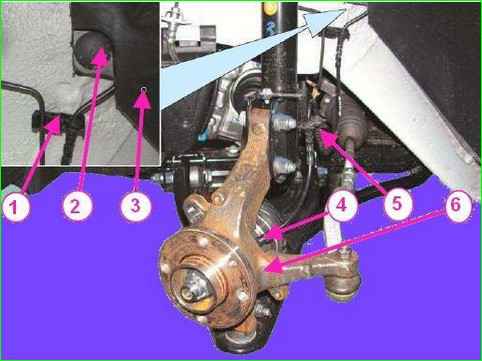

Remove retainer 2, figure 2, of the front wheel arch protective cover in the area where the speed sensor wiring harness is located (flat-head screwdriver).

Remove the speed sensor wiring harness from the slots of bracket 5 of the front suspension strut and from holder 1 on the engine compartment mudguard.

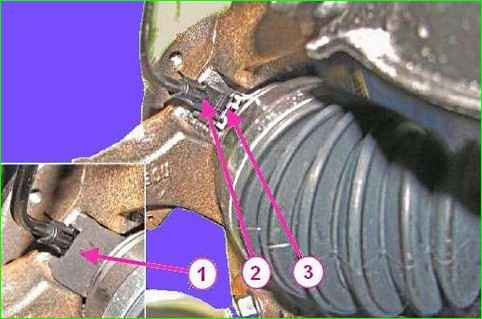

Remove the insulating foam 1, Figure 3, from the steering knuckle speed sensor mounting socket (flat-head screwdriver).

Remove the speed sensor 2 from the mounting hole on the steering knuckle by pressing the tab of the sensor retainer 3 with a screwdriver (flat-head screwdriver).

Disconnect the speed sensor wiring harness block from the front wiring harness and remove the sensor.

Installation

The insulating foam of the wheel speed sensor must be replaced.

Install the insulating foam into the speed sensor mounting groove on the steering knuckle.

Connect the speed sensor wiring harness block to the front wiring harness.

Install the speed sensor in mounting hole on the steering knuckle until the latch engages.

Install the speed sensor wiring harness into the slots of the front suspension strut bracket and into the holder on the engine compartment mudguard.

Secure the front wheel arch protective cover with a latch.

Install the front wheel.

Removing and installing the rear wheel speed sensor

Removal

Remove the rear wheel.

Raise the vehicle to a height convenient for performing work.

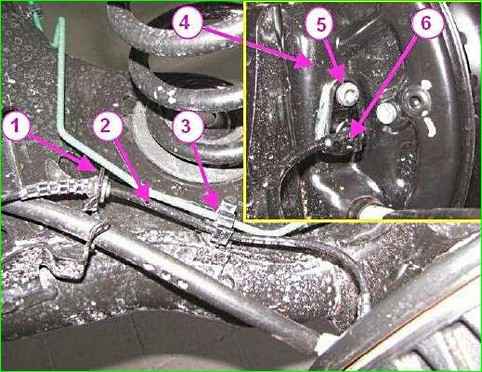

Remove harness 2, Fig. 4, of the speed sensor wires from the groove in bracket 1 and from the clamp 3 on the rear suspension arm.

Unscrew bolt 5 securing the speed sensor to the rear brake shield and remove sensor 6.

Unscrew two nuts 4, Figure 5, securing the rear wheel speed sensor protective wiring harness casing (13 mm socket, ratchet wrench).

Remove two clips 2 securing the casing and unfold casing 3 (6) to gain access to the speed sensor wiring harness connector (flat-head screwdriver).

Remove the speed sensor wiring harness from the casing holders, disconnect connector 5 of the sensor harness from harness 7 of the rear wires and remove the sensor.

Connect the speed sensor wiring harness connector to the rear ABS wiring harness and secure the sensor wiring harness in the holders casing.

Install the protective casing of the speed sensor wiring harness in place and secure it to the rear wheel arch with two clamps and two nuts.

Tightening torque of the nuts is 14 Nm (1.4 kgf.m) (replaceable head 13, ratchet wrench, torque wrench).

Installation

Install the speed sensor in the hole of the brake shield and secure it with a bolt. Tightening torque of the bolt is 14 Nm (1.4 kgf.m).

Install the speed sensor wiring harness in the bracket groove and in the holder on the rear suspension arm.

Install the rear wheel.