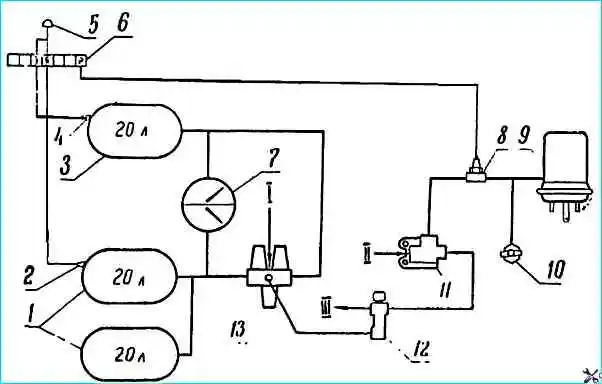

On KamAZ-5320 vehicles, air enters the emergency brake release circuit (Fig. 1) with the engine running directly from the compressor through triple safety valve 13

If the engine is not running, and the pressure in cylinders 1 and 3 of the working brake system is more than 5.0-5.2 kgf/cm 2, air from these cylinders is supplied through a triple safety valve to the emergency valve disinhibition 12.

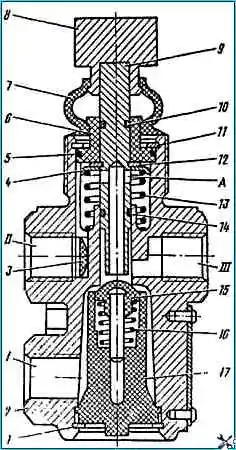

The tap (Fig. 2) is installed under the instrument panel.

Emergency brake release circuit: 1 and 3 - cylinders; 2,4 and 8 - sensors; 5 - buzzer; 6 - block of warning lamps; 7- two-pointer pressure gauge; 9 - energy accumulators; 10 - control valve; 11 - two-line valve; 12 - emergency brake release valve; 13 - triple safety valve; I - air supply from a condensation cylinder; II - air supply from the accelerator valve when the parking brake is released; III - releasing air from energy accumulators after releasing the tap button

When you press the button on tap 12, air through the tap and two-line valve 11 is supplied to energy accumulators 9 and the car is released.

After releasing the valve button, the air from the energy accumulators through the dual-line valve and then through the emergency brake release valve escapes into the atmosphere, the energy accumulators brake the car again.

Pneumatic valve: I - outlet to the receiver; II - atmospheric output; III - output to pneumatic cylinders; 1,11,12 thrust rings; 2 - body; 3 - filter; 4 - rod spring plate; 5,10,14 - sealing rings; 6 - bushing; 7 - protective cover; 8 - button; 9 - pusher; 13 - pusher spring; 15 - valve; 16 - valve spring; 17- valve guide

When the engine is not running, the air reserve in the service brake system cylinders is sufficient to release the parking brake three times.

Reducing the pressure in these cylinders to 5.0-5.2 kgf/cm 2 leads to the closure of the valve in the triple safety valve and the cessation of air supply to the emergency brake release valve.

It must be remembered that to ensure release of the brakes, the pressure in the cylinders must be 0.6-0.8 kgf/cm 3 greater than the specified value 2.

If this excess does not occur, the triple safety valve will shut off the air supply until the energy accumulators are completely released.

On KamAZ-5410 vehicles, air is supplied to the emergency brake release valve directly from the cylinders of the service brake circuit of the rear bogie.

On these vehicles, the parking brake can be released if the air pressure in the indicated cylinders drops during release to at least 4.5 kgf/cm 2.

Let's look at two of the most typical examples of using the emergency brake release circuit

In the control lamp block, the blinking light on the parking brake and lamp III came on, indicating a drop in pressure in the parking brake circuit. At the same time, the car began to lose speed until it came to a complete stop.

If lamps I and II in the control lamp block do not light up, and when you press the emergency brake release valve button, the flashing light goes out, then an air leak has occurred in the parking brake circuit up to the dual-line valve.

In this situation, the driver needs to hold down the crane button, release the brakes and, observing safety precautions, remove the car from the roadway.

On the side of the road in a calm environment, the driver must find and, if possible, eliminate the malfunction.

If the fault cannot be found or eliminated, to ensure the vehicle can be driven or towed, it is necessary to compress the springs in the energy accumulators using the emergency brake release circuit and unscrew the screws in them until they stop.

When returning to the ATP in a faulty vehicle with the power accumulators disconnected, the driver must remember that the parking and emergency brake systems are not working on the vehicle.

Therefore, he must constantly monitor the condition of the working brake system, move at a reduced speed, if necessary, stop on a horizontal platform and place stops under the wheels.