When the auxiliary brake valve button is pressed, the engine does not stop, the flaps in the exhaust pipes do not turn, the trailer does not brake

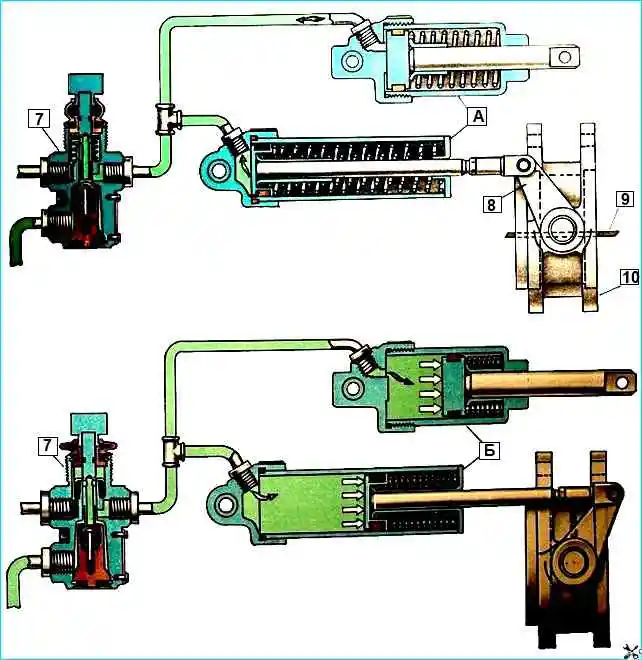

Operation of the KAMAZ auxiliary brake: 7 - auxiliary brake activation valve; 8 - auxiliary brake valve lever; 9 - valve; 10 - valve body; (A) - initial position; (B) – braking position

There may be several reasons: air is not supplied to the auxiliary brake valve, the pipeline from the valve to the pneumatic cylinders is pinched or clogged, the valve itself is faulty.

The malfunction is determined by successive disconnection of the pipelines with subsequent restoration of operability or replacement of faulty elements.

If the fuel is not disconnected when the auxiliary brake is on, and the flaps in the exhaust pipes operate, then check whether compressed air is supplied to the pneumatic cylinder on the fuel pump.

The malfunction may also be in the pneumatic cylinder mount.

Check whether the engine stop lever can be manually turned to the stop bolt.

The mechanisms of the flaps and the pneumatic cylinders that control them operate in the most unfavorable conditions.

Therefore, they often fail, most often the flaps jam.

If this happens with both flaps, the engine does not start, if with one, the engine starts, but smokes and loses power.

Some car models are equipped with one flaps.

The pneumatic cylinders of the flaps drive also have problems, the most common of which is the loss of tightness of the piston cuff.

This occurs due to thermal stress and abrasive wear (dirt gets into the cavity of the pneumatic cylinder).

The sensor for turning on the solenoid valve of the trailer is located in the left side member of the frame next to the clutch housing.

If the sensor or electrical wiring fails, when the auxiliary brake is turned on, the trailer does not brake, skidding and folding are possible road trains.

If the sensor contacts close spontaneously when they are dirty, the trailer will slow down, the brake drums will heat up, and the trailer wheels may lock.

If, after releasing the auxiliary brake valve button, the air from the pneumatic cylinders and the sensor is not released, i.e. the auxiliary brake does not turn off, then check if the atmospheric outlet in the valve is free.

In winter, it often freezes over, and a mud-ice plug forms in the atmospheric outlet, preventing air from escaping from the circuit.

And if in this case the inlet valve in the auxiliary brake valve loses its tightness, the brake will turn on spontaneously, and the engine will stall for no apparent reason.

If there is no air in the auxiliary brake circuit, the engine starts, but after a few minutes it spontaneously stops due to air being supplied through a faulty valve in the pneumatic cylinder of the fuel supply shut-off.

In this case, the valve must be repaired.

If there is no spontaneous engine shutdown, and the engine does not start while driving after releasing the auxiliary brake valve button, it is necessary to clean the atmospheric outlet of the valve.