Fix the starter in a vice

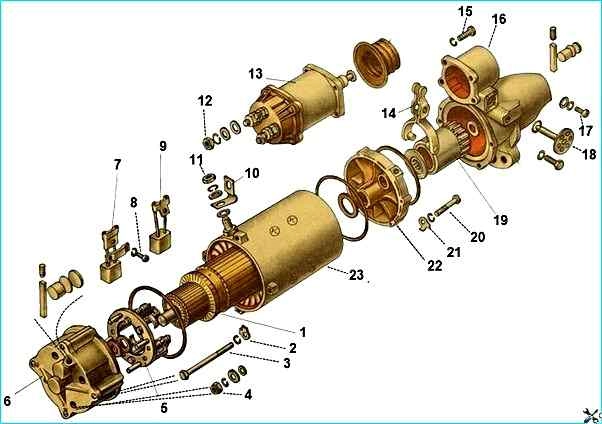

Unscrew the nuts, remove the jumper 10 connecting the relay and the housing

Unscrew the four nuts on the cover 6 on the collector side, securing the crossmember 5

Bending back the lock washers 2, unscrew the four bolts 3 and remove the cover 6

Unscrew the screws 8, securing the terminals of the excitation winding and brushes to the crossmember. Remove brushes 7 and 9 and crossmember 5

After unscrewing two screws 17 from the flange, remove the axis 18 of the lever

Unscrew four screws 15 and remove relay 13 together with the relay anchor

After bending back the lock washers 21, unscrew the bolts 20 securing the cover 16 on the drive side and remove the cover

Remove the drive 19 and lever 14 from the cover

Remove the bearing holder 22

Remove the anchor 1 of the starter from the housing 23

Wash and dry the starter parts

Check the technical condition of the parts

The following is not allowed on the starter housing:

- - soldering or breakage of contact connecting buses;

- - wear of the pole surface;

- - breakage of the contact terminal tip

Resolder the unsoldered connecting buses

Repair damage to the insulation of the pole coil windings with tack tape

Replace the broken contact terminal tip. If the insulating washers or contact terminal gaskets are damaged, replace them

Clean up nicks and burrs on the seating areas of the covers

Assembled anchor. The following is not allowed:

- - armature shaft bending more than 0.25 mm;

- - collector working surface diameter less than 52.26 mm;

- - shaft splines twisting, shaft breakage;

- - collector plates short-circuiting with each other;

- - dents on the collector surface;

- - winding turns short-circuiting with the housing or with each other;

- - winding turns protruding from the sleeve stack

Remove bending by straightening under a press

Remove wear and burnout of the collector by turning

Remove short-circuiting of the armature winding turns with the housing or with each other by rewinding the winding or replacing the anchors

Covers from the collector side. Not allowed:

- - cracks on the cover;

- - inner diameter of the bronze-graphite bushing more than 16.3 mm;

- - felt clogging;

- - cover insulation burnout;

- - brush height less than 13 mm;

- - brush spring pressure on the brushes more than 1.5-2.05 kgf;

- - brush holder groove width more than 12.25 mm

Covers from the drive side. The following is not allowed:

- - breakage of the bracket of the boss or the starter mounting eye;

- - breakage of the seat flange;

- - the inner diameter of the bronze-graphite bushing is more than 19.4 mm;

- - clogging of the felt

Starter drive. The following is not allowed:

- - cracks or breakages of the drive wheel teeth;

- - breakage of the springs;

- - wear of the wheel teeth;

- - deformation of the lead-in part of the teeth (eliminated by cleaning the ends and grinding the leads);

- - the outer diameter of the lever pins is less than 11.5 mm

Starter relay. Not allowed:

- - wear of the bellows, melting of the relay cover, burnout of the relay coil;

- - the height of the contact bolt is less than 3.5 mm;

- - the thickness of the contact disk is less than 3.5 mm

If necessary, clean the contact bolts and disks without disturbing the plane of the contact surfaces

Assembled bearing holder. The following is not allowed:

- - felt clogging;

- - cuff wear;

- - inner diameter of bronze-graphite bushing more than 25.5 mm

Starter assembly

Fix the starter housing in a vice

Install the bearing holder 22 in the starter housing

Install the anchor 1 of the starter in the housing

Install the drive 19 on the splines of the anchor shaft

Install the lever 14 in the drive

Install the cover 16 on the drive side. Install new lock washers 21 and tighten bolts 20 for fastening the cover on the drive side with a torque of 6.28-7.75 Nm (0.64-0.79 kgfm)

Install relay 13 with lever 14 and secure with screws 15 on the cover on the drive side with a torque of 2.94-4.4 Nm (0.3-0.47 kgfm)

Secure the excitation winding terminals on crossbar 5

Install crossbar 5 on the collector, place brushes 7 and 9 in the brush holders

The brushes should move easily in the brush holders without jamming and be ground to the surface of the collector. The fit of the brushes to the collector should be over the entire surface of the brushes

We install cover 6 from the collector side, install new lock washers 2 and screw in cover mounting bolts 3 with a torque of 6.28-7.75 Nm (0.64-0.79 kgfm)

We install and secure jumper 10 with nuts 11 and 12, connecting relay 13 and starter housing 23.

The tightening torque of nuts 11 is 17.6-21.6 Nm (1.8-2.2 kgfm), nuts 12 is 2.94-4.4 Nm (0.3-0.47 kgfm)

We adjust the operation of the drive by turning the axis 18 of the lever, which has two (or six) adjustment grooves

For adjustments:

- - when turning on the relay, turn the flange of the axis 18 of the lever until there is a gap of 0.5-1.5 mm from the washer on the armature shaft to the end of the drive guide. In this case, the flange grooves must match the threaded holes in the cover 16 on the drive side

- - screw in the screws 17 for fastening the lever axis flange

The starter relay contacts must not close when the drive sleeve rests on a 6 mm thick gasket inserted between the drive guide and the washer

The starter is tested on a stand

Technical conditions

In idle mode:

- - current consumption no more than 130 A;

- - voltage at the starter terminals no more than 24 V

In braking mode:

- - current consumption no more than 800 A;

- - voltage at the starter terminals no more than 18 B;

- - braking torque no more than 49 Nm (5 kgfm)