During operation, it is necessary to regularly check the oil level in the pump tank and rinse the pump filters within the time limits specified in the chemmotological card

Externally check the tightness of connections and hoses of the steering hydraulic system daily

For the hydraulic system, you need to use only clean, filtered oil, indicated in the chemical chart.

The oil must be filled through a funnel with a double mesh and a filler filter installed in the neck of the pump reservoir cover.

The use of contaminated oil causes the steering wheel to jam and rapid wear of pump and steering gear parts.

When checking the oil level, the front wheels of the vehicle must be set to a position corresponding to straight-line movement.

Before removing the filler plug to check the oil level, top up or change it, the plug or cap must be thoroughly cleaned of dirt and washed.

Oil is added while the engine is idling to the level between the indicator marks.

Power steering pump filters must be washed in gasoline.

If the filters are significantly clogged with resinous deposits, they must be additionally washed with solvent No. 646.

The articulated joints of the rods are regularly lubricated through grease nipples until a fresh layer of lubricant is squeezed out from under the rubber seals of the hinges.

Daily, by external inspection, it is necessary to check the fastening of the steering parts and their cotter pins:

- steering gear bipod on the shaft, steering rod ball pin nuts, levers in the steering knuckles,

- threaded tie rod end caps,

- steering wheel on the steering column shaft.

If the fastening is unreliable and they are poorly pinned, the parts may become separated when the vehicle moves, which can lead to an accident.

It is periodically necessary to check the absence of play in the steering rod joints, joints and splined joints of the propeller shaft, as well as the free play of the steering wheel, which should not exceed 25° (with the engine running).

Faults in the steering system manifest themselves in a decrease in vehicle stability when additional work is required by the steering wheel to maintain it, usually due to an increase in the free play of the steering wheel.

Increased free play of the steering wheel is caused by increased clearances in the joints of parts from the wheels of the steering mechanism and in the mechanism itself.

The amount of free play of the steering wheels is also affected by violation of the chassis adjustments, wear of the front wheel hub bearings and pin bushings, articulated joints of rods, etc.

To regulate the free play of the steering wheel, it is first necessary to eliminate play in the steering drive.

If there is no play in the drive, then the reason for the increased free play of the steering wheel may be the steering mechanism. It needs to be adjusted.

A sharp increase in effort on the steering wheel when driving a car is usually explained by malfunctions in the hydraulic part of the steering.

In particular, there may be air in the hydraulic system, the safety valve seat may come loose, or the pump bypass valve may become stuck. Oil leaks are also possible.

Checking and adjusting the steering mechanism is carried out with the longitudinal link disconnected and the engine not running.

The force on the steering wheel rim is measured with a dynamometer in its various positions.

When turning the steering wheel more than two turns from the middle position, the force should be within 6-16 N.

When turning the steering wheel ¾ of a turn from the middle position, the force should not exceed 23 N.

When the steering wheel passes through the middle position, the force on the rim should be 4-6 N greater than in the second position, but not exceed 28 N.

Adjustment of these parameters begins in the middle position by shifting the gear sector when rotating the adjusting screw in the steering mechanism cover.

When the screw is rotated clockwise, the force when turning the steering wheel increases, and when rotated in the opposite direction, it decreases.

A decrease in the force of turning the steering wheel in the middle position indicates wear of the steering gear in the gearing, and the car has poor road holding.

Inconsistency between the forces on the steering wheel rim in the first position indicates the need to adjust the propeller thrust bearings.

The bearings are adjusted by tightening the nut with the front cover removed.

A change in the forces on the steering wheel rim in the second position may be caused by wear or damage to the ball screw parts.

To eliminate this problem, complete disassembly of the steering mechanism is required.

The steering gear is checked and, if necessary, adjusted toe and maximum angles of rotation of the steered wheels.

To check the toe-in of the steered wheels, it is necessary to place the car on a horizontal platform in a position for straight-line movement, check and adjust the air pressure in the tires to normal.

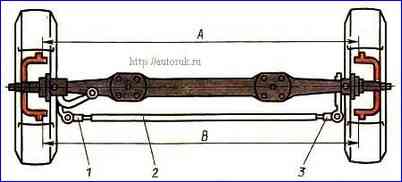

Install a telescopic ruler in front of the front axle beam horizontally between the rims at the height of the wheel axles and measure distance A

To eliminate the influence of wheel runout on the measurement results, move the car forward so that the ruler is installed behind the axle at the same height, and take a second measurement B.

The difference between the second and first measurements on a KamAZ-5320 vehicle should be within 1-3 mm, on KamAZ-4310 vehicles - 1-2 mm.

The toe-in of the wheels is adjusted by changing the length of the tie rod, rotating it with a pipe wrench with the pinch bolts of the tips loosened.

Since the curved transverse rod of the KamAZ-4310 vehicle cannot be rotated, its length is changed by rotating the tips.

To do this, in addition to loosening the coupling bolts, it is necessary to disconnect them from the steering knuckle arms.

In one revolution, the left end of the rod moves along the thread by 2 mm, and the right end by 1.5 mm.

It must be borne in mind that the trouble-free and efficient operation of the steering is determined not only by the serviceability of its components, but also by the correct operation of other components (assembly units) of the car, especially its supporting system.