KAMAZ gearbox - maintenance

Maintenance of gearboxes includes periodic checking of their tightness; tightening the fastening of the support support to the ten-speed gearbox and the car frame

levers to the remote drive rods and flange on the secondary shaft; checking and adjusting the distance between the stop and the gear divider control valve rod, which should be 20-21 mm with the clutch pedal free; checking the condition and operation of the divider control cable (the cable should move easily in the shell).

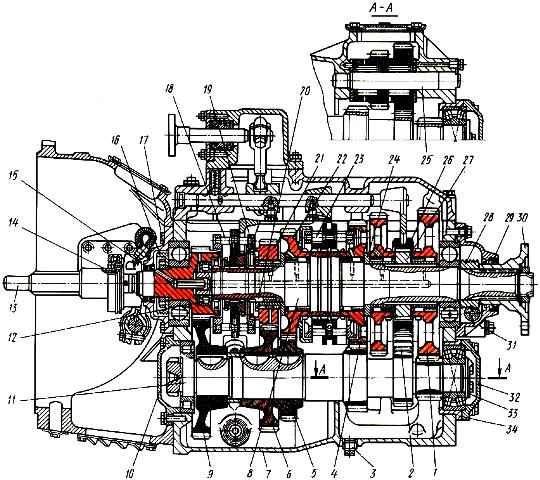

Five-speed gearbox with clutch housing in the c6ore: 1 - first gear gear of the secondary shaft; 2 - reverse gear block; 3 - drain plug; 4 - second gear of the secondary shaft; 5 - third gear of the intermediate shaft; 6 - fourth gear of the intermediate shaft; 7 - crankcase; 8 - secondary shaft; 9 - intermediate shaft drive gear; 10 - cover of the front bearing of the intermediate shaft; 11 - intermediate shaft; 12 - ring nut for fastening the bearing; 13 - input shaft; 14 - clutch release clutch; 15 - cuff; 16 - oil injection ring; 17 - cover of the rear bearing of the input shaft; 18 - synchronizer for fourth and fifth gears; 19 - thrust washer; 20 - lock key of the thrust washer; 21 - fourth gear gear of the secondary shaft; 22 - third gear gear of the secondary shaft; 23 - synchronizer for second and third gears; 24 - reverse gear bushing; 25 - axis of the reverse gear block; 26 - reverse and first gear clutch; 27 - first gear bushing; 28 - speedometer drive worm; 29 - cuff of the secondary shaft bearing cover; 30 - flange; 31 - cover of the rear bearing of the secondary shaft; 32 - rear cover of the intermediate shaft; 33 - thrust washer; 34 - bearing cup

The cable must be periodically lubricated by disconnecting it from the switch and pouring transmission oil into the cable sheath using an oil can.

In accordance with the chemical map, it is necessary to lubricate the supports of the front and intermediate links of the remote control drive through grease fittings, maintain the required oil level in the crankcase and change the oil in the gearbox crankcase once a year.

To check the oil level, you need to unscrew the plug with the indicator. When checking, the pointer should be inserted into the hole until the end of the plug stops in the crankcase.

Oil from the crankcase of a ten-speed gearbox must be drained through three holes, two of which are located in the lower part of the main box crankcase, and the third in the lower part of the divider crankcase.

The five-speed gearbox housing is drained through two holes.

When changing the oil, you should wash the gearbox crankcases with engine oil in the amount of 8.5 liters for a five-speed gearbox and 12 liters for a ten-speed gearbox, clean the magnetic plugs from metal particles and fill the oil to the top mark on the indicator.

The oil level is measured 3-5 minutes after filling it.

When the car is moving, the gearbox should operate without noise and vibration, the gears should be easy to switch and securely locked.

Strong uniform or pulsating noise may indicate excessive wear of gear teeth and shaft bearings, looseness of the shaft bearing caps, insufficient level or poor quality of oil in the crankcase.

Difficulty engaging all gears is usually a consequence of incomplete disengagement of the clutch. To eliminate the malfunction, you need to adjust the clutch and its drive.

Engagement of second, third, fourth and fifth gears with shocks and grinding noises occurs when the cone rings blocking the chamfers of the pins and carriages of the corresponding synchronizers are severely worn.

To eliminate the malfunction, you need to replace worn parts.

Shocks and grinding noises observed when turning on the gear divider can be caused by a malfunction of its synchronizer, as well as an increase in pressure in the pneumatic system for controlling the divider due to contamination of the air channels of the ventilation cap in the gear shift valve of the divider.

The pressure reducing valve must provide an outlet pressure of 395-445 kPa.

If it is determined that there is no air release in the gear shift valve of the divider, then it is necessary to remove and disassemble the valve, wash all its parts including the ventilation cap.

The gears in the gearbox do not engage due to wear of parts and improper adjustment of the mechanical remote drive, destruction of the secondary shaft bearings or broken; adjusting the stop position of the divider gear shift valve.

Gears They can turn off spontaneously when the vehicle is moving due to wear of some parts, malfunction and violation of the remote drive adjustments, as well as due to malfunction of the switching mechanism clamps, loosening of the blocks and levers.

Oil leakage from the gearbox housing occurs when the cuffs of the output shafts wear out and lose elasticity, which must be replaced in these cases, and when the pressure in the crankcase increases due to a clogged breather.

If there is leakage along the sealing surfaces, it is necessary to tighten the fasteners and replace the gaskets.