The gearbox is removed to repair the gearbox, as well as to repair clutch parts

The gearbox weighs about 32 kg, so it is better to remove it with two people

If there is no assistant, to be on the safe side, support the box with a hydraulic stop or a reliable stand.

Removing the gearbox

Install the car on an inspection ditch or lift.

Disconnect the wire from the negative terminal of the battery.

Drain the oil

We disconnect the driveshaft from the gearbox, article - How to remove the driveshaft of a Gazelle car

From the cabin, using a slotted screwdriver, lift up the corrugated cover of the gear shift lever.

Use a screwdriver or a socket to pry off the locking sleeve.

Remove the upper part of the lever together with the cover.

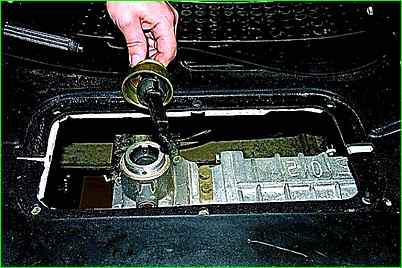

Use two screwdrivers to open the sectors of the spacer sleeve and remove the sleeve.

Remove the rubber cushion

Remove the locking sleeve.

For ease of subsequent assembly, install the parts of the upper arm into its internal cavity in the reverse order of removal and secure them with a locking sleeve.

Use a screwdriver to unscrew the six screws

Remove the floor seal.

Remove the protective cover.

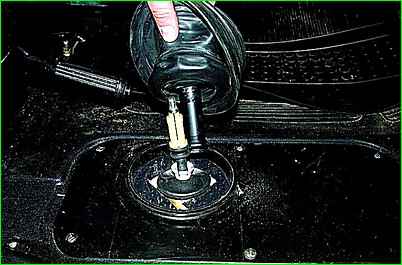

Use your hand or pliers to unscrew the cap

Take out the lever

At the bottom of the car, disconnect the speedometer drive cable and the reverse light switch wires from the gearbox.

Holding the bolt securing the exhaust pipes with a “12” wrench, use a “14” wrench to unscrew its two nuts.

Using a 14mm wrench, unscrew the two bolts to attaching the bracket to the gearbox.

Remove the bracket along with the rubber washers.

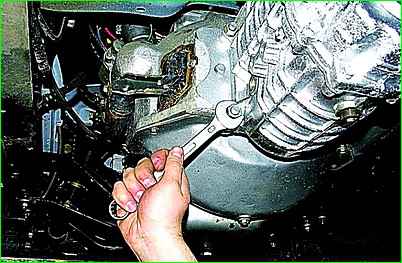

Using a 19mm wrench, unscrew the four nuts securing the gearbox to the clutch housing.

We install a stop under the power unit or place a block between the block head and the engine compartment shield.

Unscrew the two nuts securing the gearbox to the cross member and remove the cross member.

Carefully rocking and moving the box back, remove it.

Install the gearbox in reverse order, lubricating the input shaft splines with CV joint-4 grease.