Over time, tarry deposits from crankcase gases accumulate in the engine crankcase ventilation system, making it difficult to remove these gases into the engine cylinders for combustion

As a result, the gas pressure inside the engine increases and oil leaks appear through the seals

To avoid this, periodically clean and flush the system

You will need a flat blade screwdriver.

Loosen the clamps and remove the crankcase ventilation and oil separator purge hoses from the cylinder head cover pipes.

Loosen the clamps and remove the crankcase ventilation hose from the throttle body.

Rinse the hoses with gasoline or kerosene, blow with compressed air and dry.

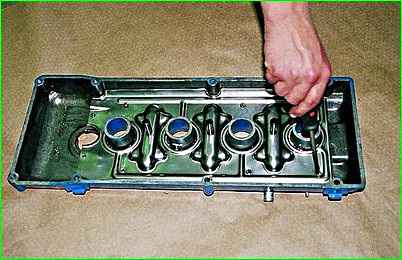

Use a screwdriver to unscrew the six screws securing the oil deflector

Removing the oil deflector

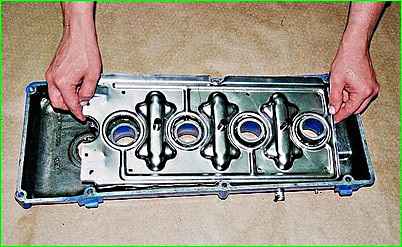

We wash the oil separator and the cylinder head cover in kerosene. We degrease the mating surfaces and screws securing the oil deflector and valve covers

Apply glue and sealant to the oil deflector

Place the oil deflector in place and press firmly

Tighten the oil deflector mounting screws, applying anaerobic sealant to their threads.

Clean the holes in the fittings for connecting the hoses.

Install all parts in reverse order

The operation of the crankcase ventilation system can be checked as follows: when the engine is running at minimum crankshaft speed at idle, there should be a vacuum in the engine crankcase.

This is determined using a water piezometer connected to the engine crankcase through a pipe for the oil dipstick.

If the system is not operating normally, there will be pressure in the crankcase. This is possible in case of coking of the ventilation channels or excessive breakthrough of gases into the engine crankcase.