Thermal clearances in the valve mechanism are designed to ensure a tight fit of the valve on the seat when the valve drive parts expand during engine operation

The size of the thermal gap at the intake and exhaust valves is set to the same and is adjustable within 0.25-0.30 mm.

When re-checking the clearances after cranking the crankshaft of an adjusted engine, they may change to within 0.20-0.35 mm due to errors in the shape and location of the surfaces of the timing mechanism parts, which is acceptable.

If the thermal clearances are too large, the lift height of the valves decreases, as a result of which the filling and cleaning of the cylinders worsens, shock loads increase and wear on the parts of the gas distribution mechanism increases.

With very small gaps, as a result of thermal expansion of the gas distribution mechanism parts, a tight fit of the valves to the seats is not ensured, gas-dynamic processes in the engine cylinders are disrupted, and the power and technical and economic indicators of the engine deteriorate.

In addition, reducing the clearance in the exhaust valve drive can lead to overheating of the valves and their burnout.

Adjust thermal clearances on a cold engine or no earlier than 1 hour after stopping it.

When adjusting thermal clearances and checking them again, it is recommended to press the valve rocker arms:

- - on the head of the right row of cylinders, the rocker arms of the exhaust valves are to the end of the axle, of the intake valves - to the thrust washer;

- - on the head of the left row of cylinders, the rocker arms of the exhaust valves are to the thrust washer, the intake valves are to the end of the axle.

The exhaust valves of the right bank of cylinders are located closer to the fan, and those of the left bank of cylinders are closer to the flywheel.

Adjustment sequence:

- 1. Turn off the fuel supply.

- 2. Unscrew the bolts securing the cylinder head covers and remove the covers.

- 3. Check the tightening torque of the rocker arm axle bolts, which should be 120-150 Nm (12-15 kgcm).

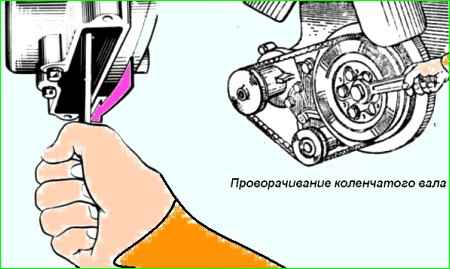

- 4. Rotating the crankshaft clockwise (when viewed from the fan side) from the front with a wrench by the pulley mounting bolt or from the back by a crowbar on the flywheel through the hatch in the lower part of the flywheel housing, using the holes in the flywheel (Fig. 1), set the moment when the intake valve of the first cylinder will rise completely (that is, close).

Continuing to rotate the crankshaft, turn it about ⅓ more turns (120°). This position of the crankshaft corresponds to the compression stroke in the first cylinder and both valves of this cylinder will be closed.

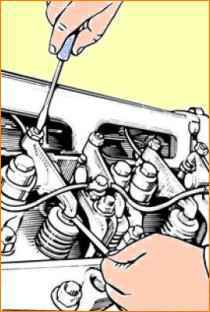

- 5. Using a feeler gauge, check the gap between the valve end and the rocker arm tip at the intake and exhaust valves of the first cylinder and, if necessary, adjust.

- 6. To adjust the gaps, unscrew the nut of the adjusting screw, insert a feeler gauge into the gap and, turning the screw with a screwdriver (Fig. 2), set the gap to 0.25-0.30 mm.

Hold the screw with a screwdriver, tighten the nut and check the gap.

With a correctly adjusted gap, a 0.25 mm thick probe should enter with light pressure, and a 0.30 mm thick probe with force.

- 7. To adjust the valve clearances of the remaining cylinders, turn the crankshaft in the same direction until the intake valve of the adjustable cylinder is completely closed and an additional ⅓ turn. Adjust the gaps as indicated above (see point 6).

It is recommended to adjust the clearances of the cylinders in accordance with their operating order 1-4-2-5-3-6. The cylinder numbering scheme is given in the article “Engine Features.”

- 8. After completing the adjustment of the gaps, start the engine and listen to its operation.

There should be no knocking in the valve mechanism. If there is a characteristic valve knock, stop the engine and repeat the clearance adjustment.

- 9. Install and secure the cylinder head covers, check the condition of the gaskets. Oil should not leak where the covers meet.