For every hour of operation, more than 800 m3 of air is sucked into the engine cylinders, which, especially in conditions of heavy dustiness, is clogged with many tiny grains of sand, which are stronger than steel in their hardness

If these particles get into the engine cylinders together with air, then it. abrading the surface of the cylinders, piston rings and fingers, in a short time will bring the engine to an inoperable state.

On KamAZ vehicles, a two-stage dry-type air cleaner is used in the air supply system; passing through it, the sucked air is cleaned of dust by inertial method and filtration.

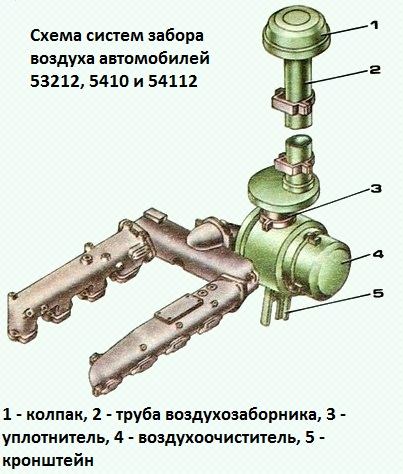

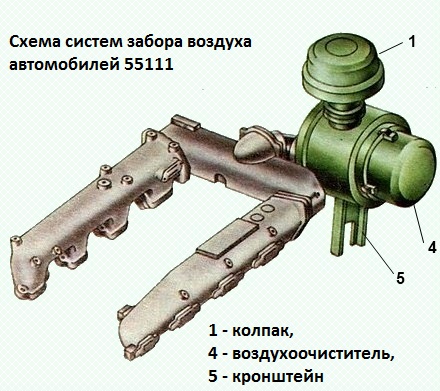

The figure shows the air intake systems used on various models of KamAZ vehicles.

Air is taken into the engine through the air intake.

Between the coarse air intake and the air ducts mounted on the engine, a seal is provided - a corrugated rubber pipe, inside of which a pressure disk is inserted, which serves as a support for the spacer spring. The latter ensures the tightness of the connection between the seal and the coarse air intake when the cab is in a tailor-made position.

The air cleaner for 4 KamAZ-5320 and KamAZ-55102 vehicles is attached to the left side member of the frame.

On other vehicles, the air cleaner is mounted on bracket 5.

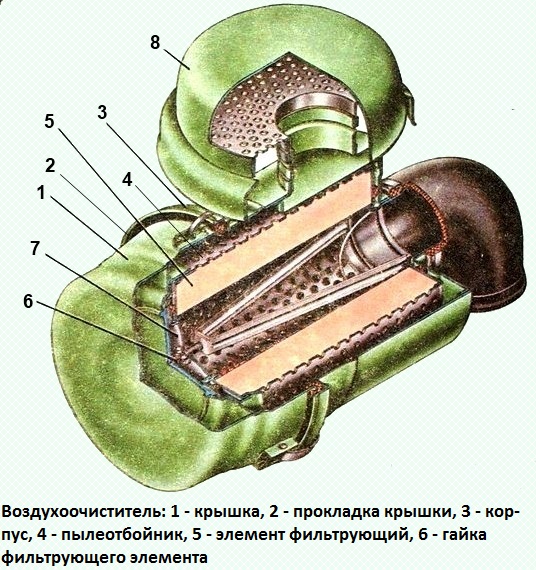

Dry type air cleaner, two-stage. The first stage is centrifugal - a monocyclone with the collection of separated dust in a hopper, the second stage - a paper filter element.

The air cleaner consists of a body 8, a filter element 5, a cover 1 attached to the body with four latches.

The tightness of the connection is ensured by gasket 2

In the inner cavity of the cover there is a partition with a slot and a plug, which forms a dust collection cavity (bunker).

At the inlet pipe of the air cleaner there is a dust deflector 4. The filter element is fixed in the housing with a self-locking nut 6.

Sucked air through the inlet pipe enters the filter.

The dust separator creates a rotational movement of the air flow in the annular gap between the housing and the filter element, due to the action of centrifugal forces, dust types are thrown to the housing wall and collected in the hopper through a slot in the partition.

Then the pre-cleaned air: passes through the filter element where it is finally cleaned.

To clean the hopper from dust, remove the cover, remove the plug from the hole in the baffle, remove dust and wipe the hopper.

The cover should be installed so that the arrow on the bottom points upwards with the filter horizontal (KAMAZ-55111, KamAZ-5410, KamAZ-54112 vehicles).

Clean air from the air cleaner enters the engine intake manifolds.

In order to increase the efficiency of cleaning the air entering the engine and increase the life of the filter element, a pre-cleaner is installed in the air cleaner.

The pre-cleaner is a sheath made of non-woven filter cloth, which is put on the filter element before installing it in the filter housing.

The intake air ducts are bolted to the side surfaces of the cylinder heads from the camber side through sealing paronite gaskets and connected to the intake channels of the cylinder heads.

The air intake ducts of the left and right halves of the unit are connected to each other by a connecting pipe. The branch pipe is bolted to the air duct flanges.

The connections between the spigot and the intake air ducts are sealed with rubber gaskets.

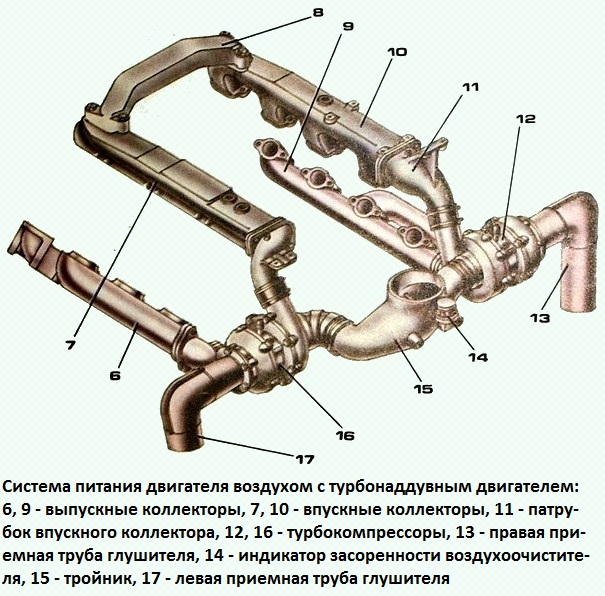

The air supply system of the KAMAZ-7403 engine differs from the KAMAZ-740 engine in the installation of an air cleaner, the design of air ducts, intake manifolds and pipes.

Clean air from the air cleaner through the tee enters the two centrifugalpressors and under an overpressure of 70 kPa (0.7 kgf / cm2) in maximum power mode is supplied through the intake manifolds to the cylinders.

The connection of the air supply tee with compressors and compressors with intake manifolds is provided by rubber pipes and hoses, which are tightened with clamps.

Dust Indicator

The degree of clogging of the air cleaner is judged by the indicator signal. It is installed in the cab and is connected by a pipeline to the engine intake manifold.

When the air cleaner is contaminated above the permissible norm, the vacuum in it increases so much that the indicator is triggered, i.e. the red drum 2 closes the indicator window and does not return to its original position after the engine is stopped.

This signal indicates the need for maintenance of the air cleaner.

To reset the drum 2 to its original position, just turn the disk 1 until it clicks in the direction indicated by the arrow.

When the limit vacuum of 6.86 kPa (0.07 kgf/cm2) is reached in the intake manifolds of the engine, the indicator is triggered - the red section of the drum closes the indicator window and remains in this position after the engine is stopped.

This indicates the need for air cleaner service.

Air filter maintenance

Clean the air cleaner paper element, precleaner and hopper, to do this:

To remove dust, remove the cover, unscrew the fastening nut, unscrew the plugs from the holes in the partition, remove dust and wipe the hopper.

The cover must be installed with the arrow pointing up when the air cleaner is horizontal (models 55111, 5410, 54112).

The filter element and the pre-cleaner can be cleaned by blowing or washing, after removing the pre-cleaner from the filter element.

Purge is effective in case of dust pollution without soot.

For purging, it is necessary to direct dry compressed air inside the filter element at an angle to the surface of its inner casing under a pressure of no more than 3 kgf/cm2. The element must be blown until dust is completely removed.

Clean the precleaner by shaking or blowing.

To check the condition of the filter element cardboard, you need to illuminate it from the inside with a lamp and inspect the cardboard through the holes in the outer casing. For convenience, you can move the filter curtain.

If there are tears or other through damage to the cardboard, the element must be replaced.

Rinsing the filter element

Rinsing is used when the pre-cleaner and filter board are contaminated with dust, soot, oil, fuel.

Rinse the filter element in a warm (temperature 40-50 °C) aqueous solution of neutral detergents (20-25 g of powder per 1 liter of water), followed by rinsing in clean water.

Since rinsing leaches phenolic resins from the filter curtain cardboard, as a result of which the strength of the cardboard decreases, it is recommended to wash the filter element no more than 3 times.

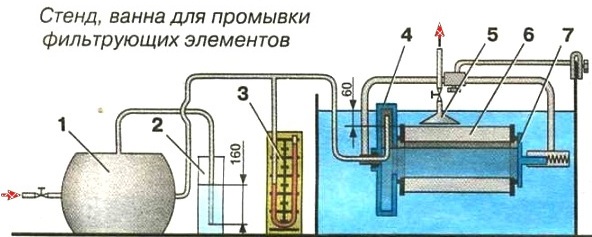

After washing, it is recommended to check the filter element by pressing it with compressed air in water in the following order:

- install a wet filter element 6 between covers 4 and 7, then immerse it in water to a depth of 60 mm.

Before testing or directly in the test facility, soak the dry filter element in water for 5-10 minutes to fill the pores in the cardboard with water; supply air at a pressure of 1.6 kPa (160 mm w.c.) to the air cylinder 1 and thus inside the element.

This pressure is maintained by a constant liquid valve 2, the tube of which is immersed in water to a depth of 160 mm and is controlled by a pressure gauge 3.

In order to avoid destruction of the filter curtain element, the air pressure should not increase even briefly above 2.0 kPa (200 mm of water column);

- slowly rotate the element, paying attention to the release of air bubbles from its outer surface; bring a transparent cap 5 filled with water to the place where air bubbles are released and measure the time it takes to fill it with air.

When filling the cap with a volume of 0.5 l in less than 20 seconds through one damage to the filter element incull.

Dry the serviceable filter element, as well as the precleaner, thoroughly before installing it on the car.

Do not dry with an open flame or hot (temperature over 50 °C) air.

When installing the filter element and precleaner on the car, check the integrity of the rubber gaskets.

It is not allowed to contact the outer casing with the precleaner (the casing can be straightened).

If, after servicing the filter element and pre-cleaner by washing or blowing, the clogging indicator is triggered when the vehicle mileage is less than before the next TO-1, replace the filter element and pre-cleaner.

Once a year, check the accuracy of the air cleaner clogging indicator.

If the vacuum deviation at the moment the indicator is triggered is more than 0.5 kPa (50 mm w.c.) from the vacuum set for the engine of 7.7 kPa (700 mm w.c.), replace the indicator.