The nozzle is an electromechanical valve in which the shut-off valve needle is pressed to the seat by a spring

When an electrical impulse is applied from the control unit to the electromagnet winding, the needle rises and opens the nozzle hole, through which fuel is supplied to the engine inlet pipe.

The amount of fuel injected by the injector depends on the duration of the electrical pulse.

Reduce the pressure in the power system if the engine has just been stopped.

Disconnect the wire from the negative terminal of the battery.

Remove the receiver.

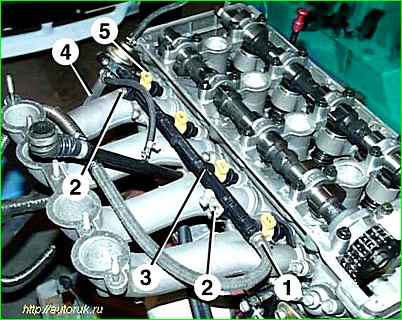

Loosen the clamps and disconnect the fuel supply hose 1 from the engine fuel line 3.

Disconnect fuel drain hose 4 from the pressure reducing valve.

Disconnect the connectors with wires from connectors 5 of the four injectors

Remove the injector from the engine fuel line. The injector is fixed in the hole in the fuel line only with the help of an O-ring.

Unscrew the two fastening bolts 2 and carefully remove the fuel line 3 of the engine, removing the injectors from the holes in the intake pipe.

The injectors are fixed in the holes of the intake pipe only with the help of O-rings.

Install the new injector in reverse order.

Checking the injectors

To check the tightness of the injector valve, you need to lower the sprayer of 1 injector into a container with gasoline or kerosene and apply compressed air under pressure (~3 kgf/cm 2).

If air bubbles come out of the injector nozzle, the injector valve is leaking and the injector must be replaced.

To check the serviceability of the injector electromagnet winding, apply a direct current of 12 V to the injector connector.

In this case, a characteristic click should be clearly audible, indicating the opening of the nozzle valve.

If this does not happen, then the injector is faulty and must be replaced.

This check can be carried out without removing the injector from the vehicle.

The resistance of the injector solenoid winding can be checked with an ohmmeter by connecting it to the contacts of the injector connector.

Resistance should be within 15.5-16 Ohms.

If the resistance value does not fall within the specified limits, replace the injector.

For more details, see the article - How to check and replace the engine injectors of a Gazelle car