The injector is used to inject and atomize fuel supplied to the diesel cylinders.

The MMZ 245.12 diesel engine uses a closed-type injector with hydraulic needle lift control

The injector is strictly fixed relative to the combustion chamber and is secured in the cylinder head with bolts

The diesel engine is equipped with injectors (part number 17.1112010-01).

The injector markings are applied to the body.

The injectors are installed with a sprayer mod. 145.1112110 or Motorpal (Czech Republic).

Use of other models of sprayers is not allowed.

The sprayer is a vulnerable unit of the fuel supply system.

Breach of the seal between the conical surfaces of the sprayer body and the needle, loss of needle mobility; decrease in fuel injection start pressure, deterioration in atomization quality and increase in atomizer throughput due to wear of nozzle holes are the main injector defects,

The injector performance test should be performed during vehicle maintenance.

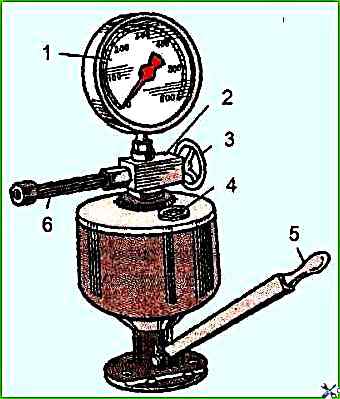

It is recommended to evaluate the injector performance on test benches at a full stroke rate of the manual testing device lever of 60-80 per minute.

Fig. 2 shows a device for checking injector nozzles and adjusting the injection pressure mod. "Motorpal" NS 50.

When using the KI-9917 device, the start of fuel injection by the injectors can be checked without removing them from the diesel engine.

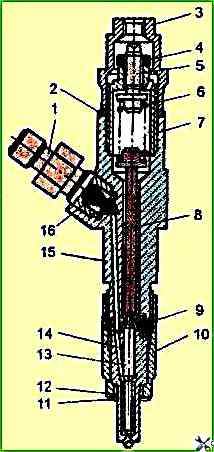

The start pressure of fuel injection is adjusted by turning the adjusting screw 5, having first unscrewed the cap and loosened the lock nut 4, (Fig. 1).

The pressure recorded at the moment of start of fuel injection should be - 21.6-22.4 MPa;

After adjustment, tighten the lock nut and cap. Tightening torque - 80-100 Nm.

The quality of fuel atomization should be checked on the adjusted nozzle.

It is considered satisfactory if the fuel is atomized to a mist-like state and distributed evenly in the cross-section of the jet cone from all five nozzle holes.

Abundantly flying drops, solid streams and thickenings are not allowed. The start and end of injection must be clear.

Fuel leakage from the nozzle after injection is complete is not allowed.

The tightness of the shut-off cone of the nozzle needle must be checked by creating a pressure in the nozzle that is 1.0-1.5 MPa less than the injection start pressure.

The tightness is considered broken if, within 15 seconds, the fuel flows in drops and forms a build-up visible to the naked eye on the nozzle tip under the nozzle holes.

If fuel leaks or the needle jams, the nozzle must be replaced or repaired.

If the nozzle holes are coked, disassemble the nozzle, rinse the nozzle and clean the holes.

It is recommended to clean the nozzle holes with a steel wire with a diameter of 0.3 mm.

Before assembling the nozzle and needle, which are a precision pair, must be thoroughly washed in clean gasoline and lubricated with filtered diesel fuel.

To check the smooth movement of the needle in the sprayer body, it should be pulled out of the body by one third of the length of the guide surface.

When the sprayer is tilted at an angle of 45°, the needle should smoothly, without stopping, completely descend under its own weight.

The nozzle must be disassembled in the following sequence:

- - unscrew the cap 3 (see. fig. 1) and loosen lock nut 4;

- - unscrew adjusting screw 5 by 2-3 turns, thereby loosening spring 6;

- - unscrew nozzle nut 10;

- - remove nozzle 11.

Violation of the disassembly procedure may lead to breakage of the pins centering the nozzle.

Before installation in the injector, new nozzles must be depreserved by washing them in gasoline or under heated diesel fuel.

The injector must be assembled in the reverse order of disassembly. The tightening torque of the nozzle nut is 50-70 Nm.

After assembly, it is necessary to repeat the injector operability check in the sequence specified above.

During assembly, it is necessary to replace the sealing gasket 12.

When installing injectors on a diesel engine, their mounting bolts must be tightened evenly in 2 - 3 steps. The final tightening torque is 20-25 Nm.